1/5 scale K2 black panther tank

#27

Thread Starter

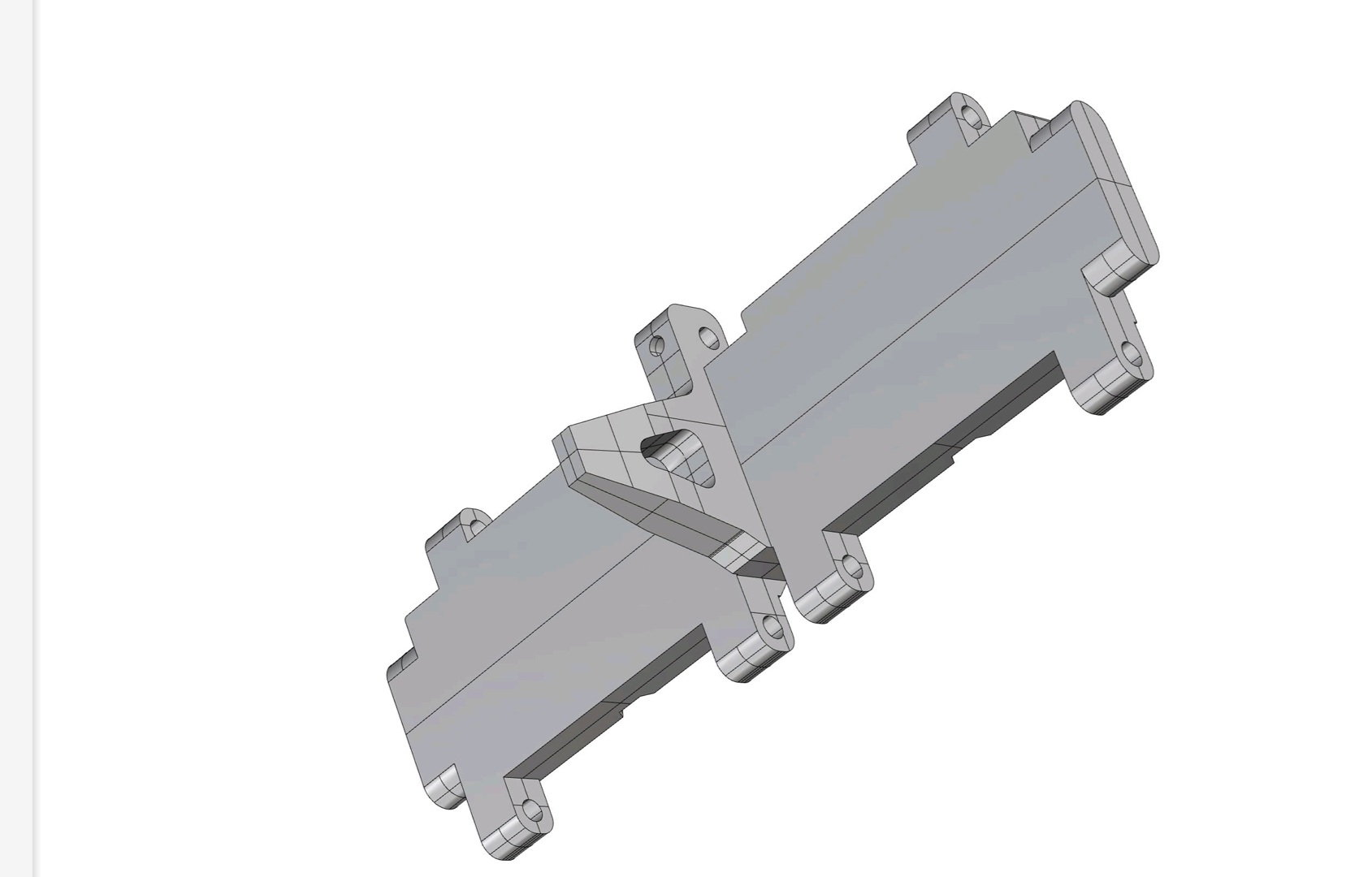

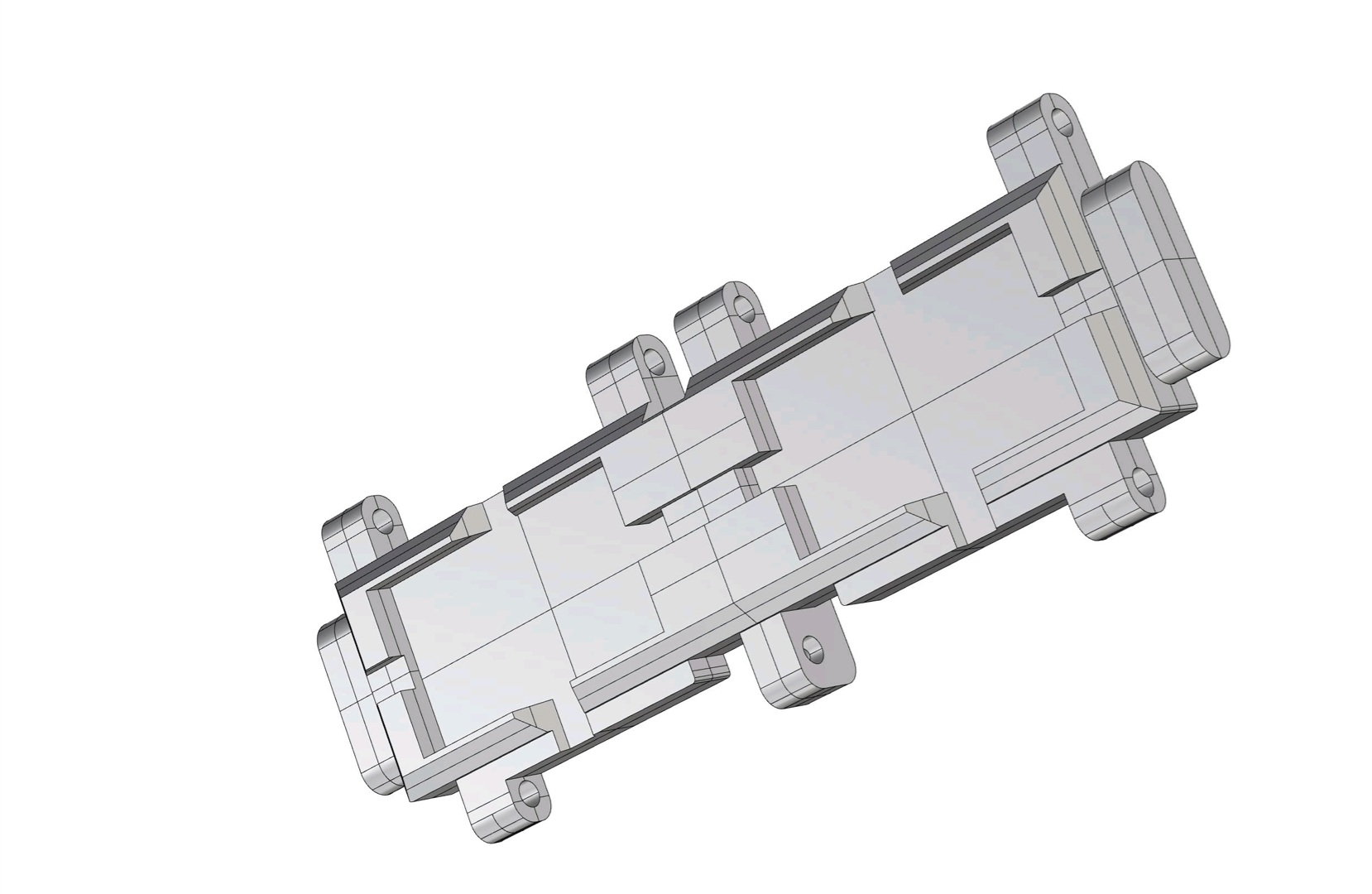

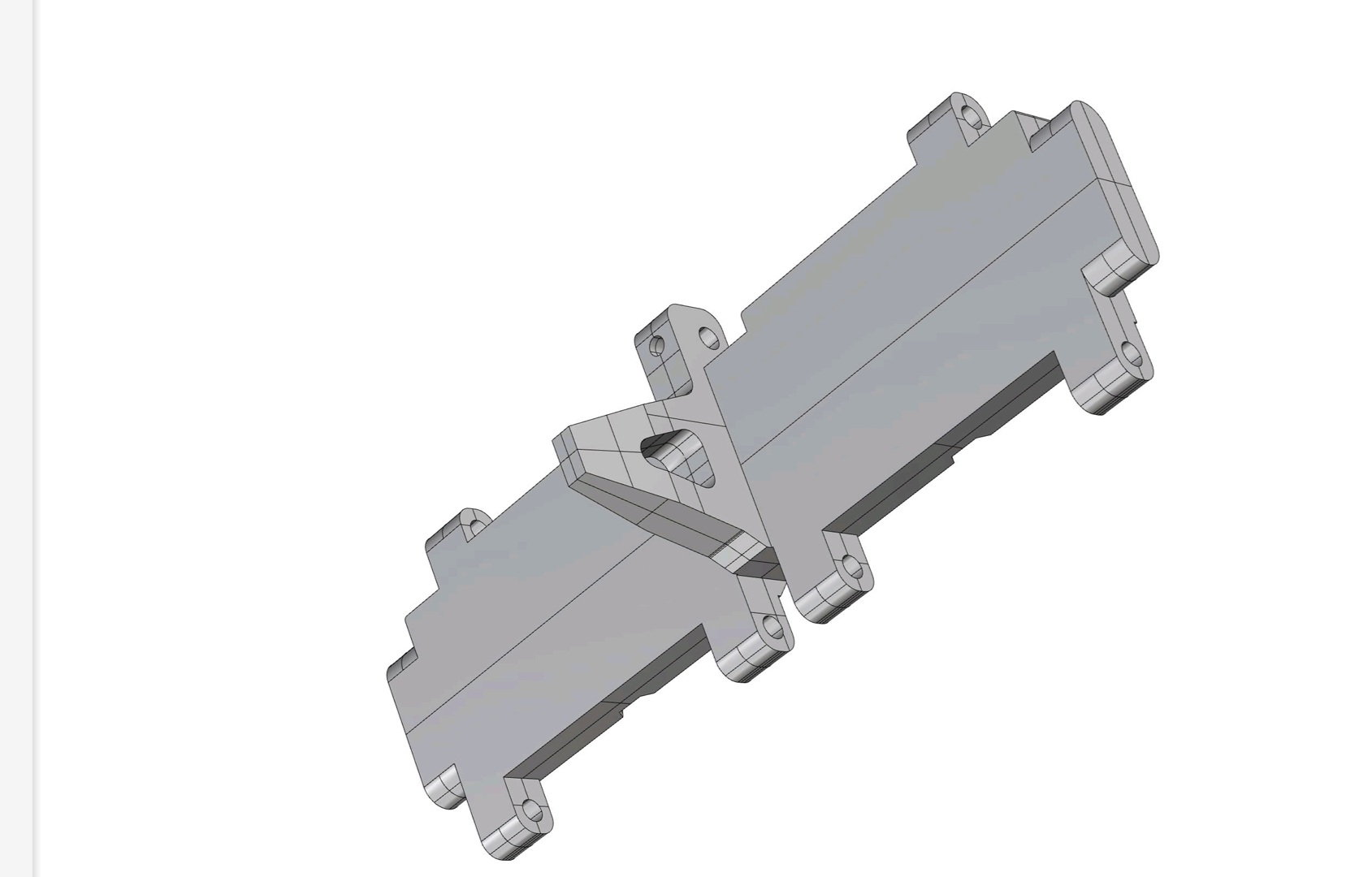

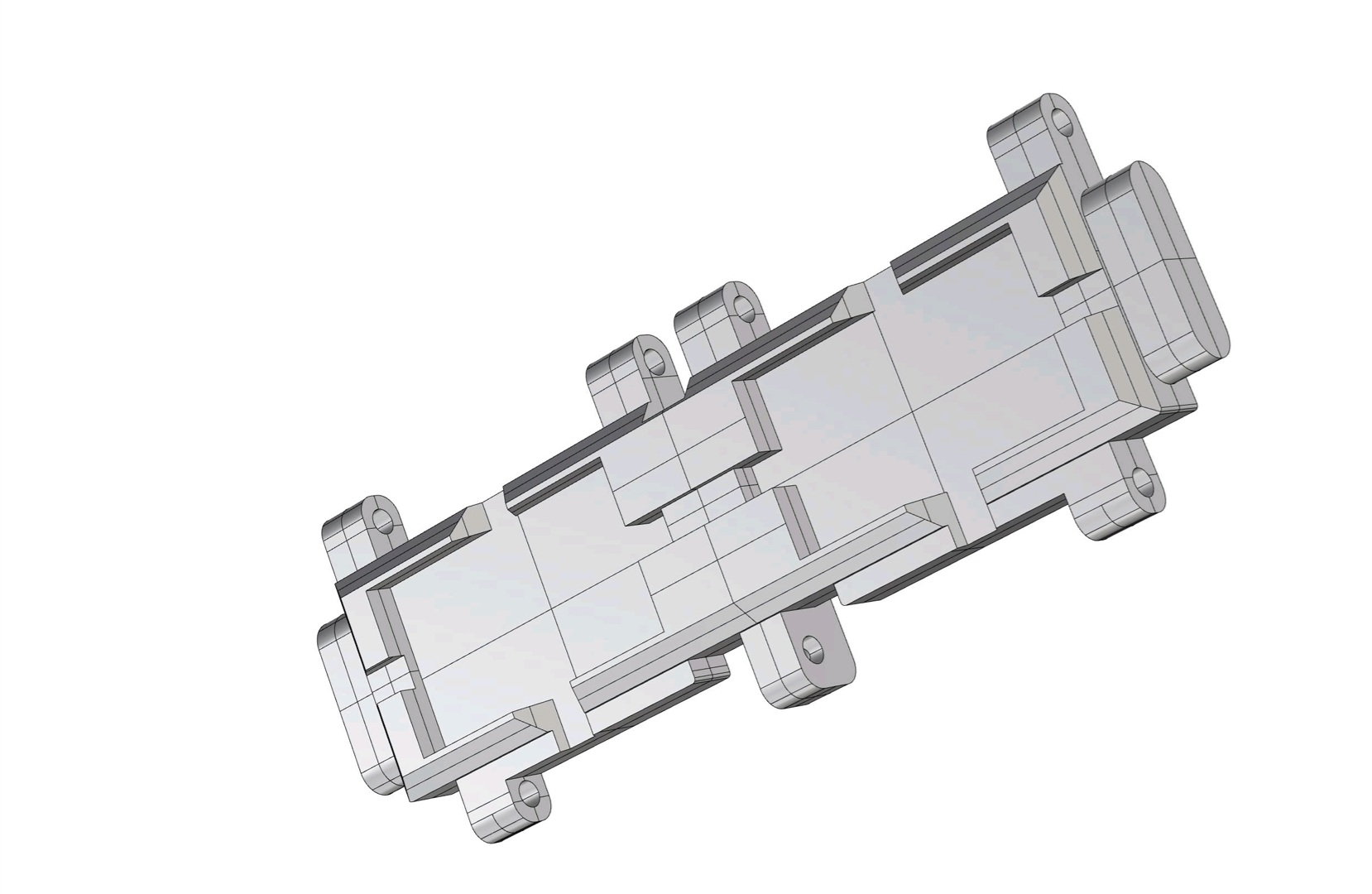

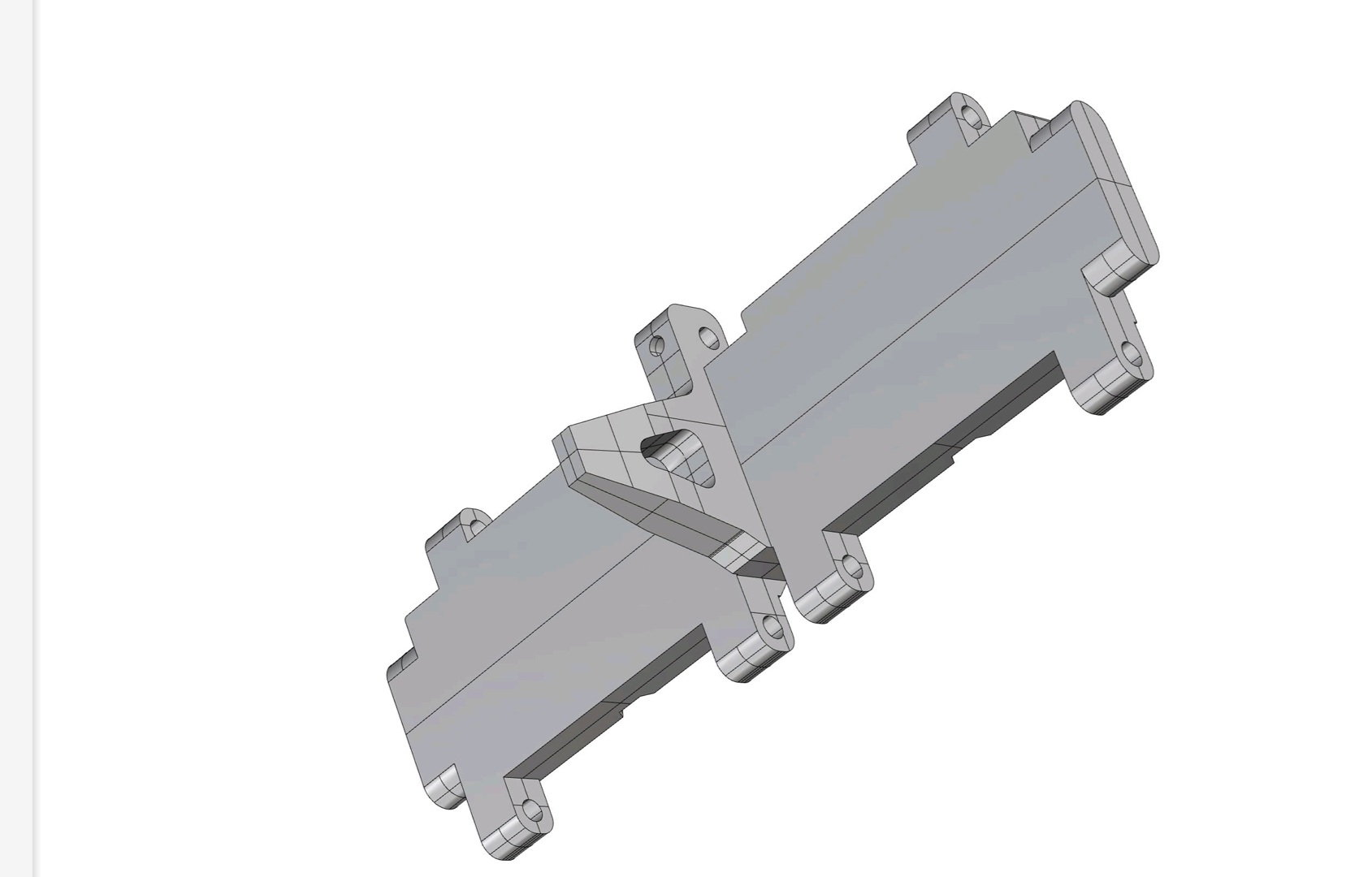

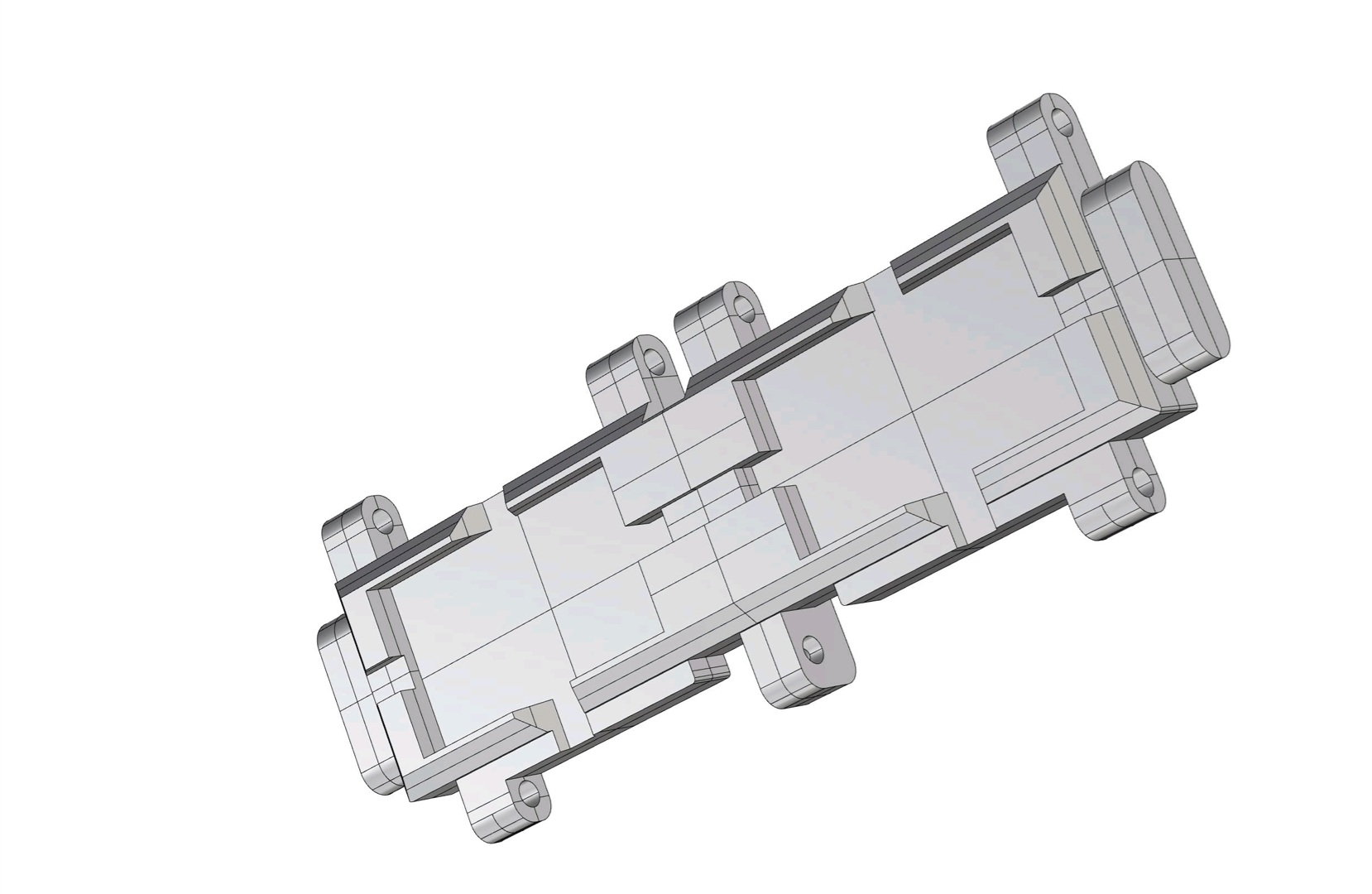

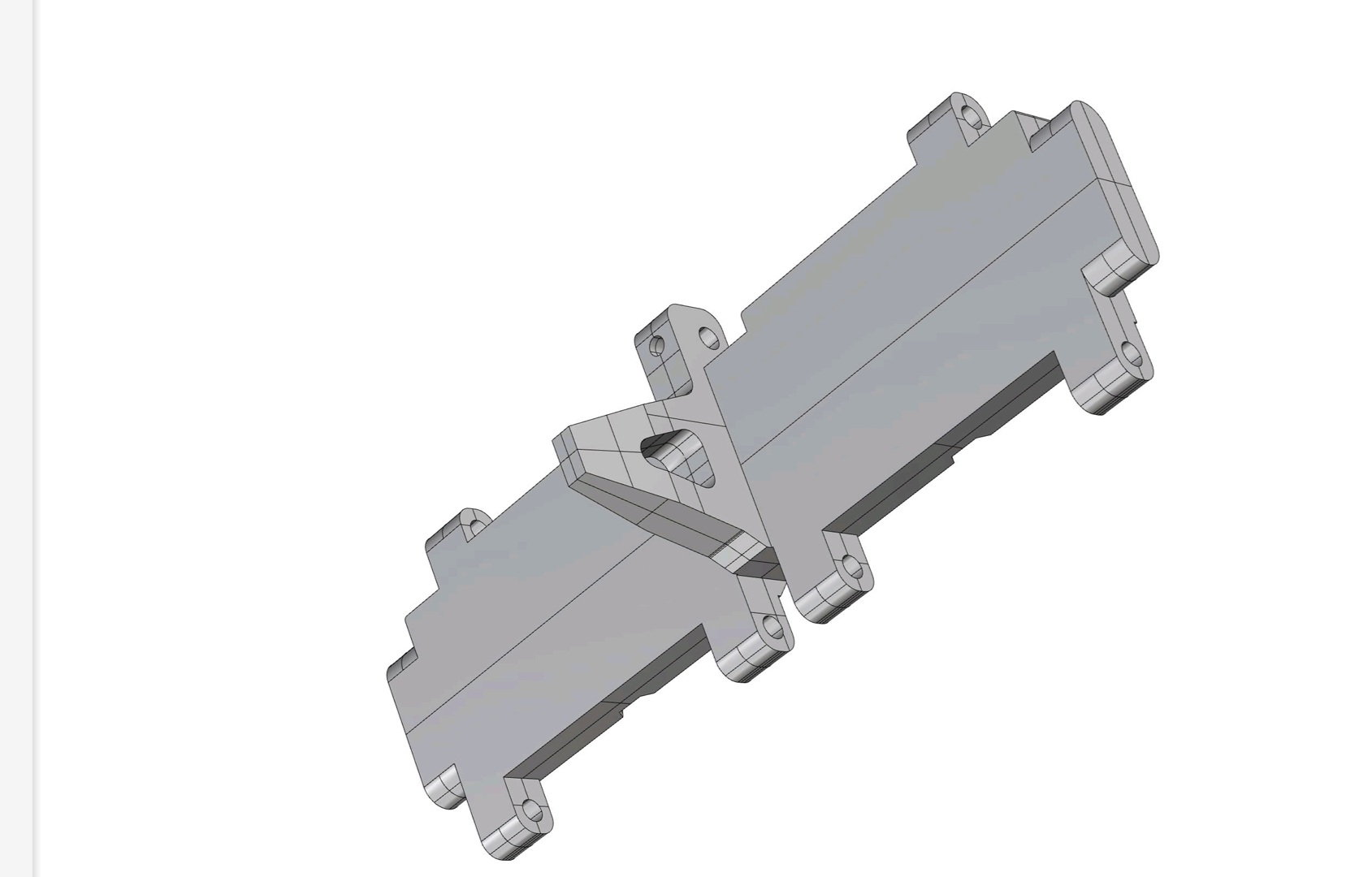

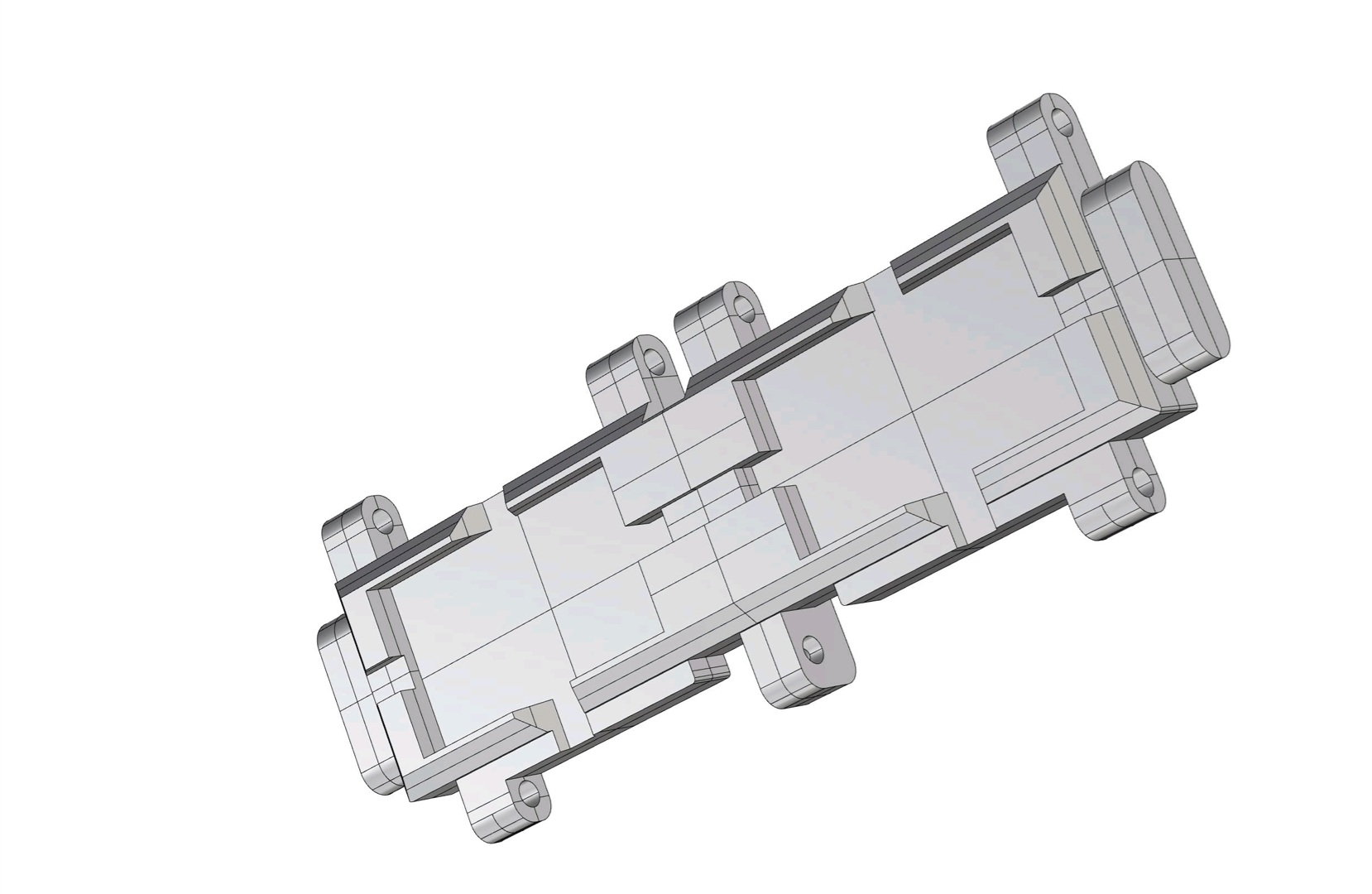

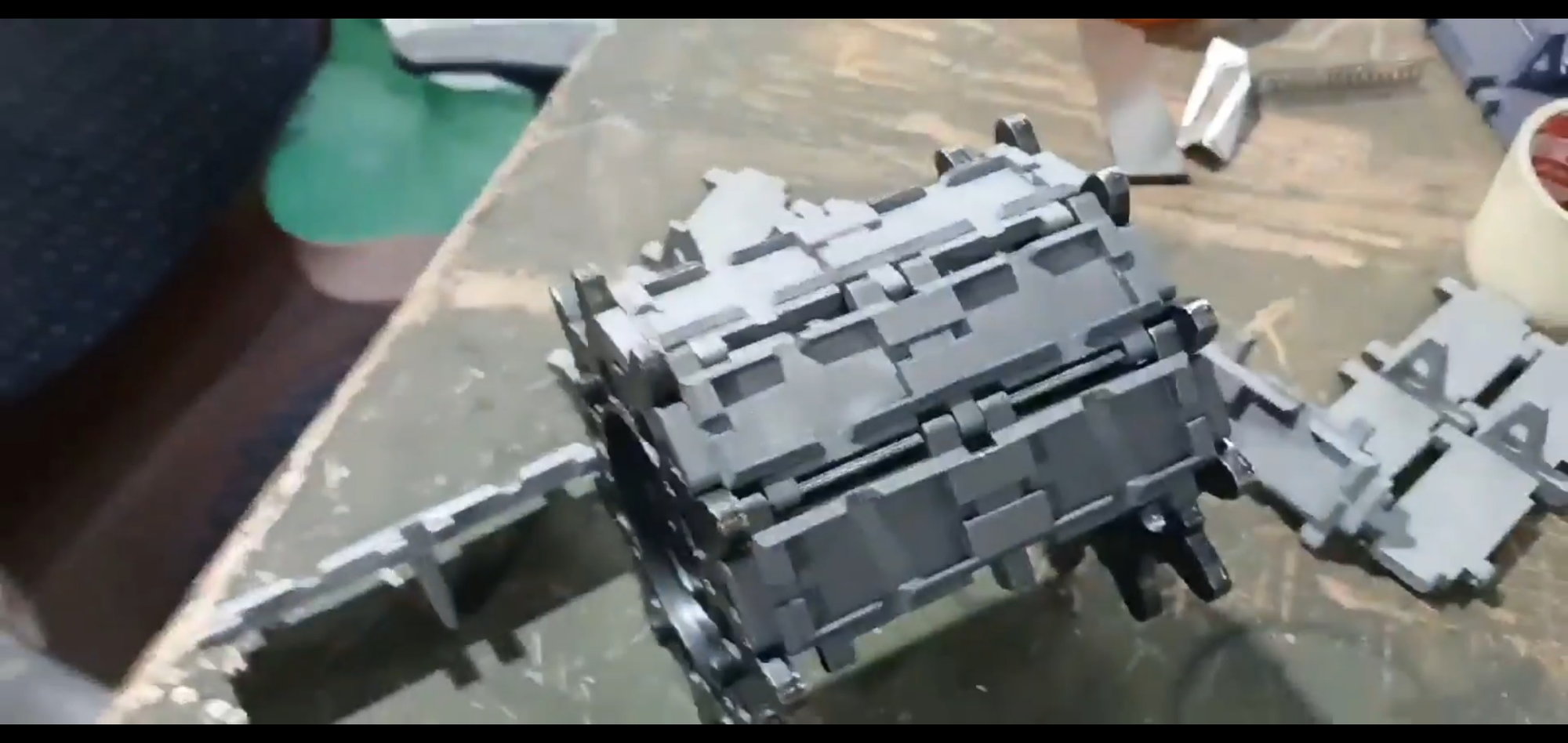

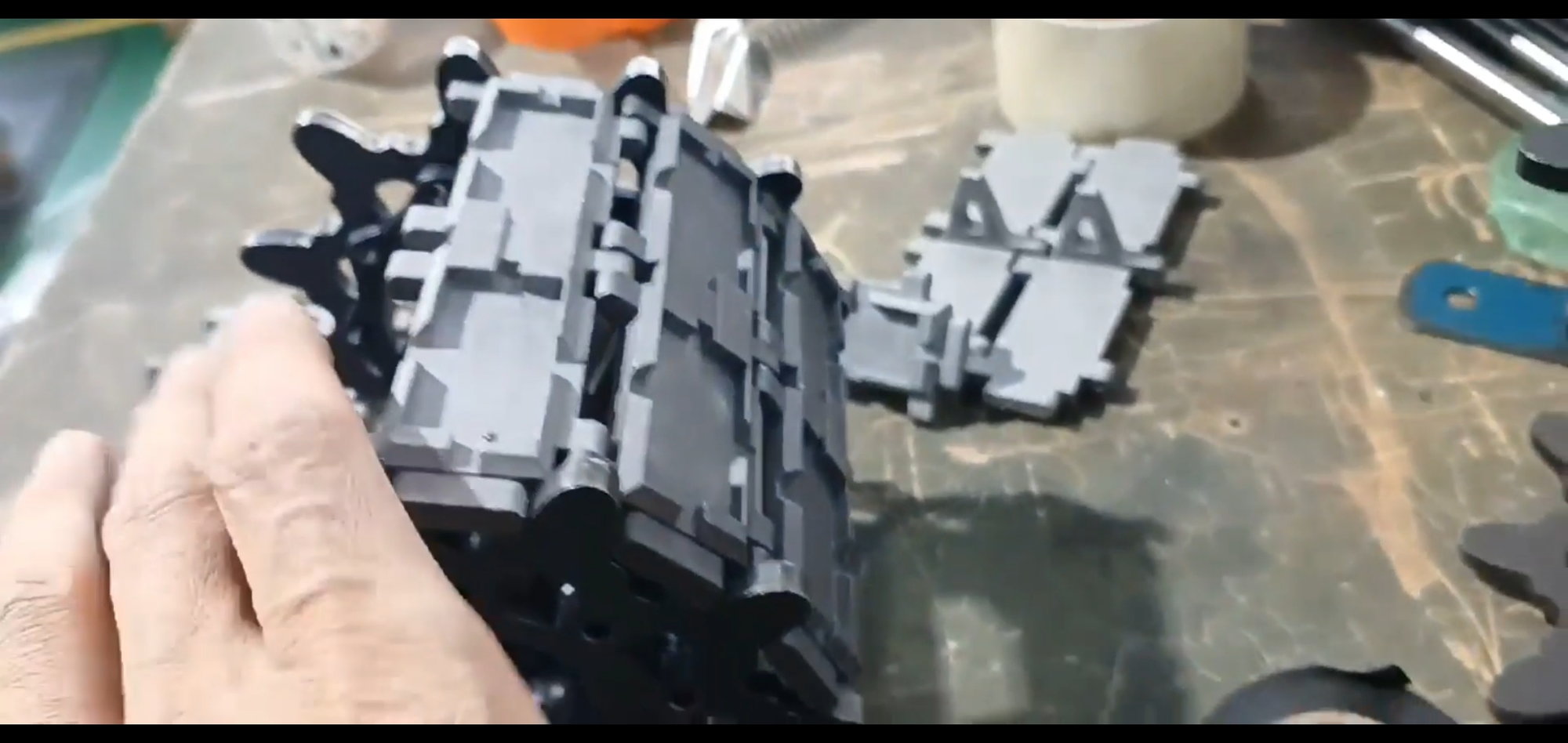

The tank manufacturer decided to manufacture and install the caterpillar of the 2023 1/5 scale Black Panther tank (project name: ic2504) by casting method. The optimal method is to increase production efficiency and reduce the number of iterations.

The shape of the track is somewhat different from the actual one, but it is strong and has increased assembly efficiency.

The production is outsourced processing, and the outsourced production has been requested today.

Regards,

Young

Upper shape of caterpillar

the lower appearance of the caterpillar

The shape of the track is somewhat different from the actual one, but it is strong and has increased assembly efficiency.

The production is outsourced processing, and the outsourced production has been requested today.

Regards,

Young

Upper shape of caterpillar

the lower appearance of the caterpillar

Last edited by PE YOUNG; 03-13-2023 at 12:53 AM.

#28

Some pretty awesome work there. Very motivating for me!

#29

Thread Starter

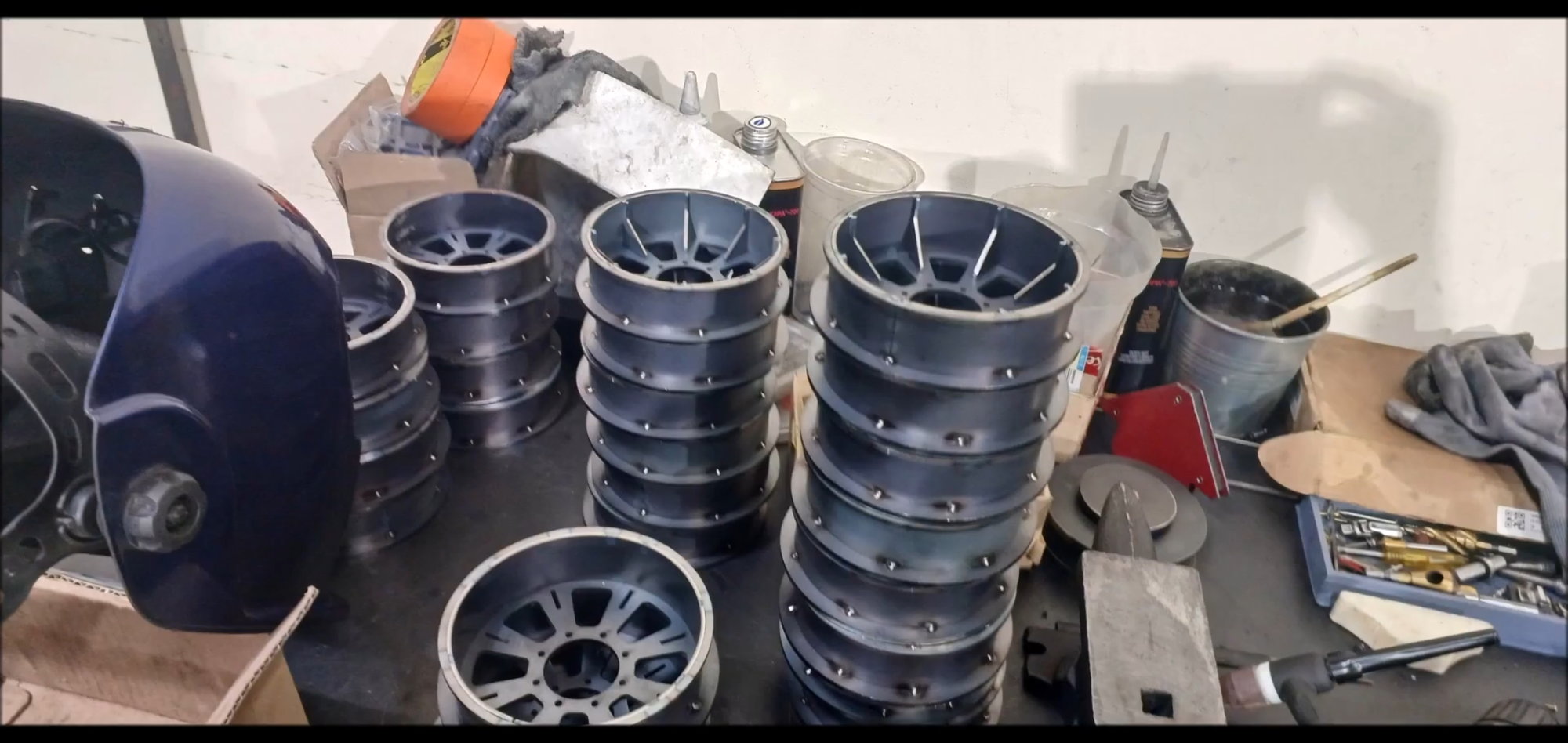

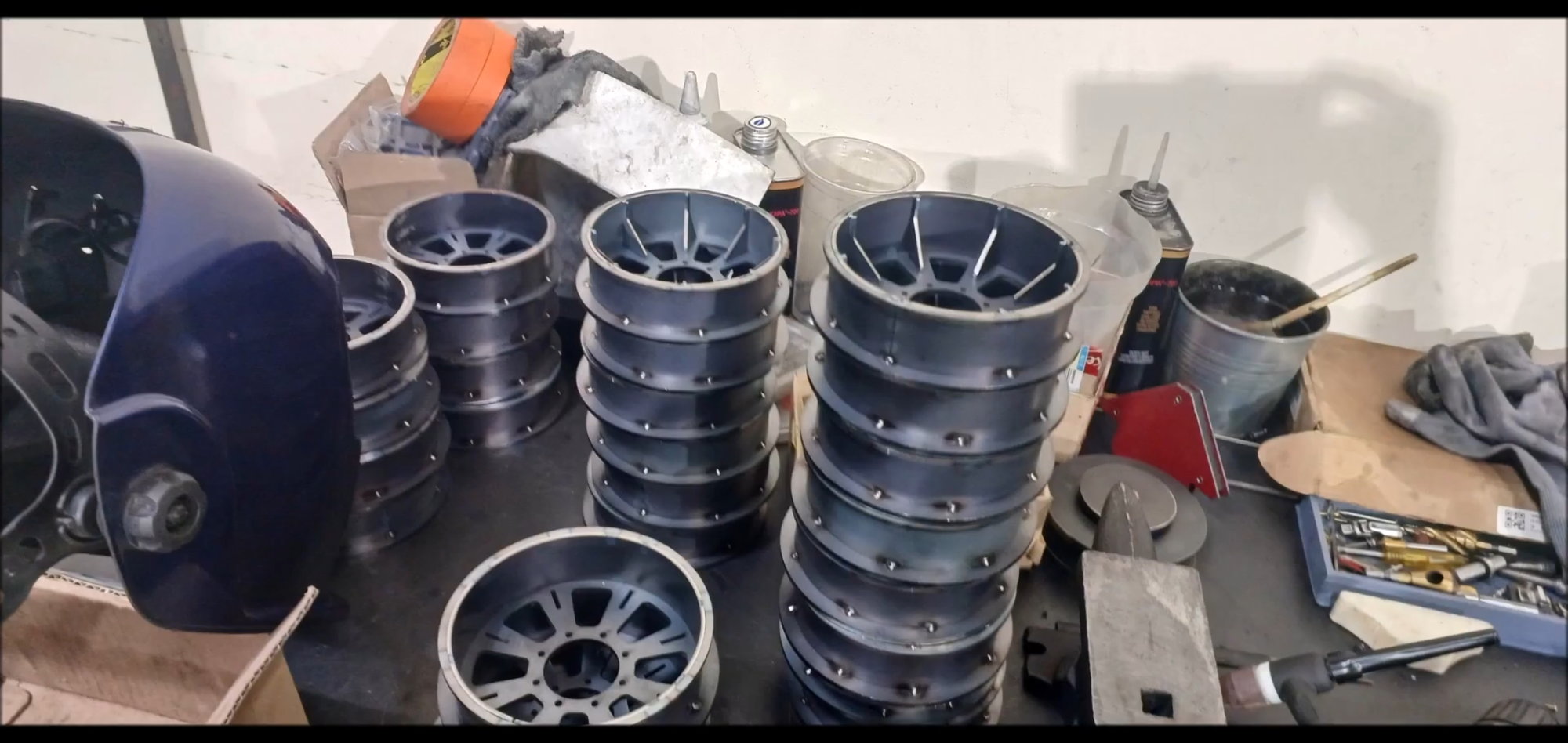

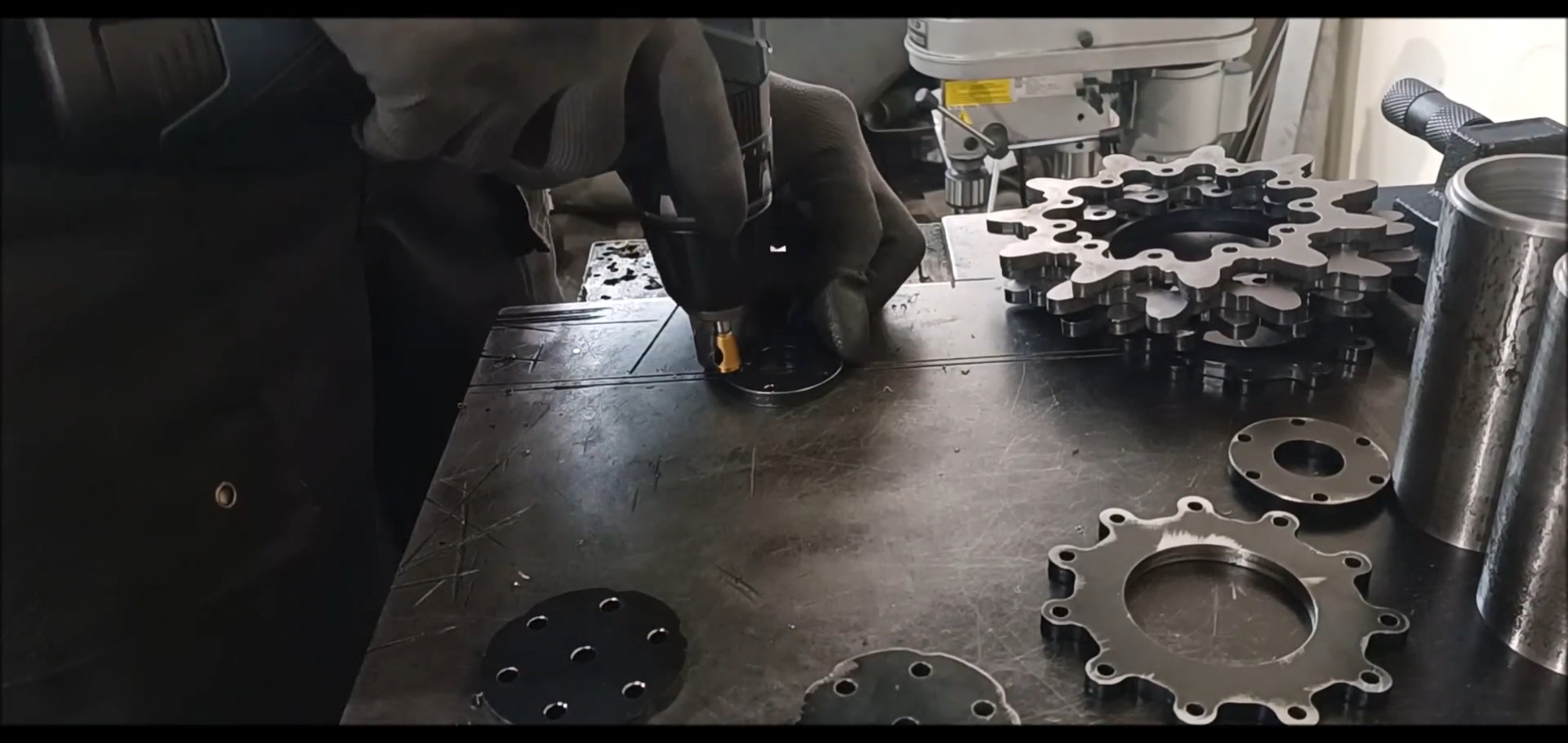

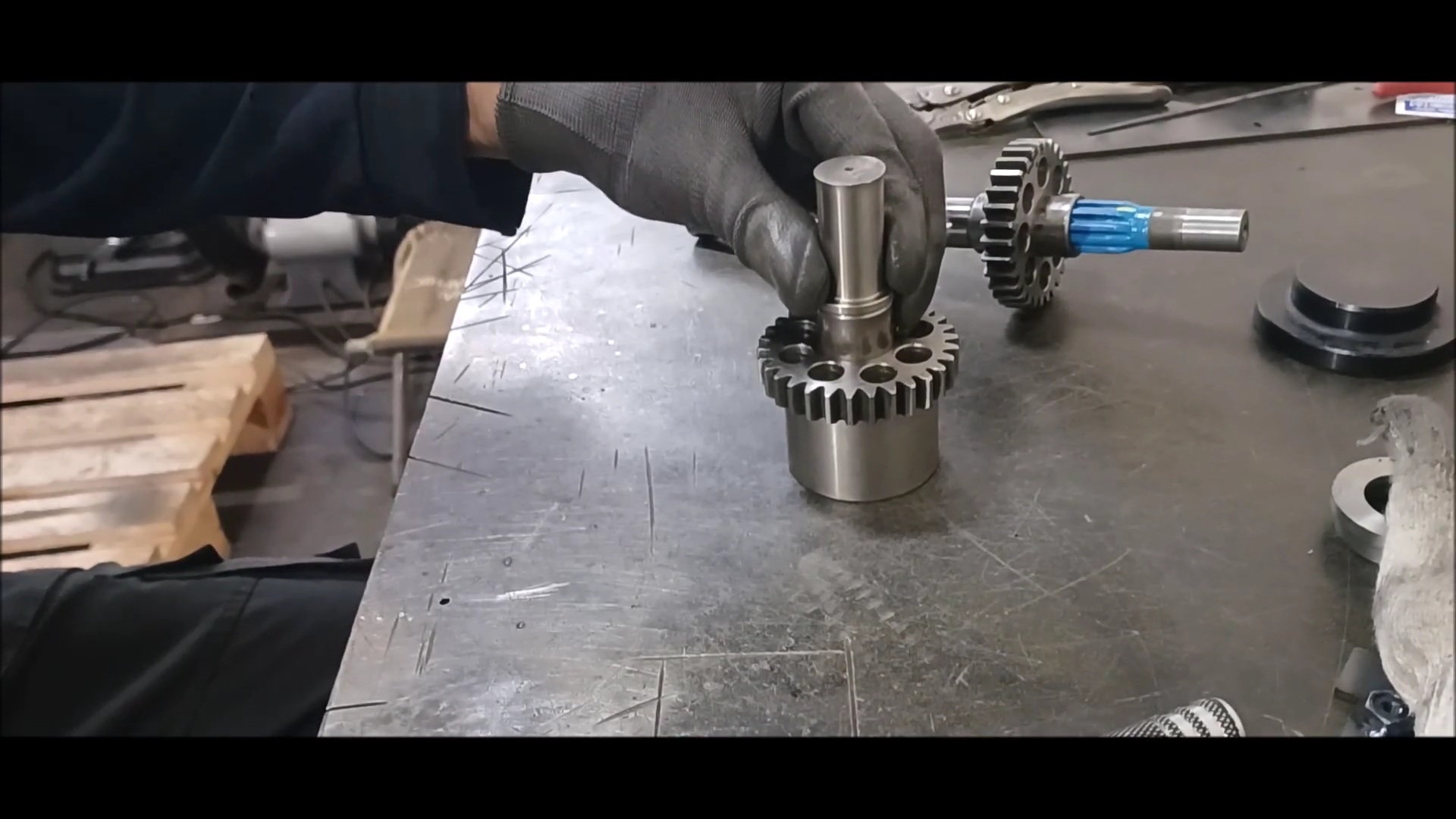

This week, the shape of the bogie wheel has been completed, it has been trimmed, and the production of the bearing insertion type connection joint has been completed.

Regards,

Young

Bogie Wheel Work Continues Last Week

Install spokes on the viewing wheel

Spoke operation completed

Create detailed parts with 3D printers

Identical drive wheel cover

Flanges to secure the same drive wheel cover

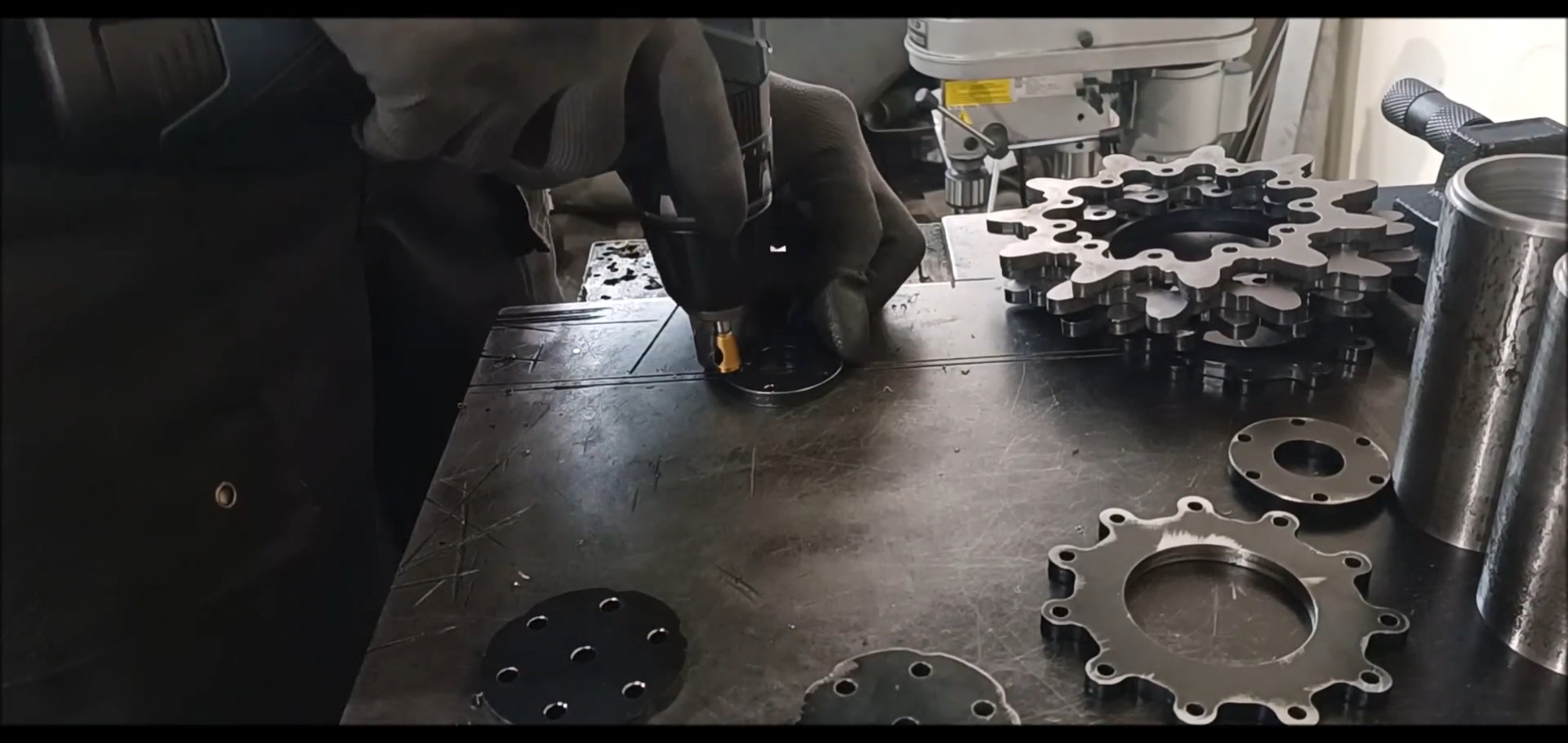

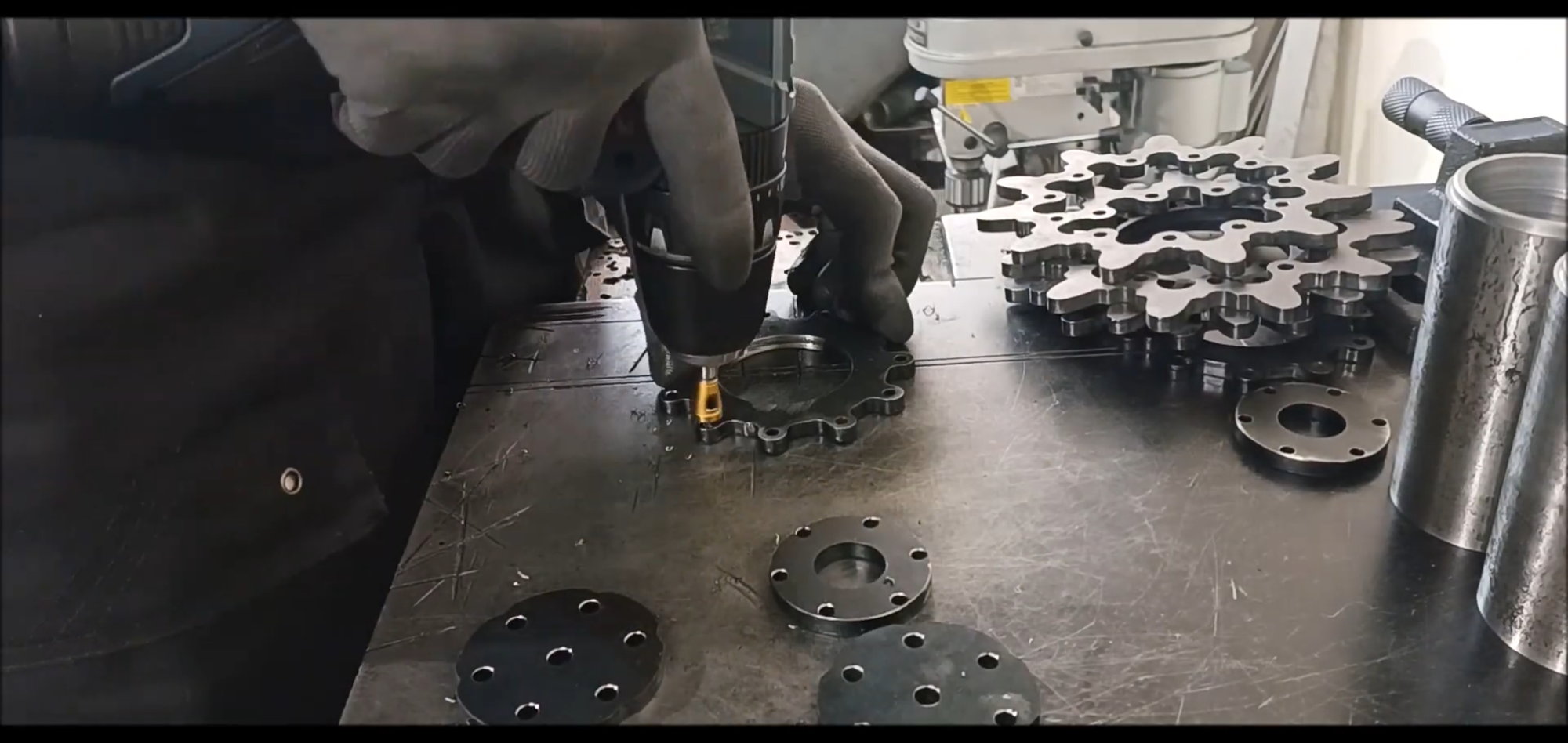

Remove the burrs on the rear of the bogie wheel with a hand grater.

Finish with a flat grinder

The sharp edges go smoothly, too.

Completing the grinder operation

Stand by for next action

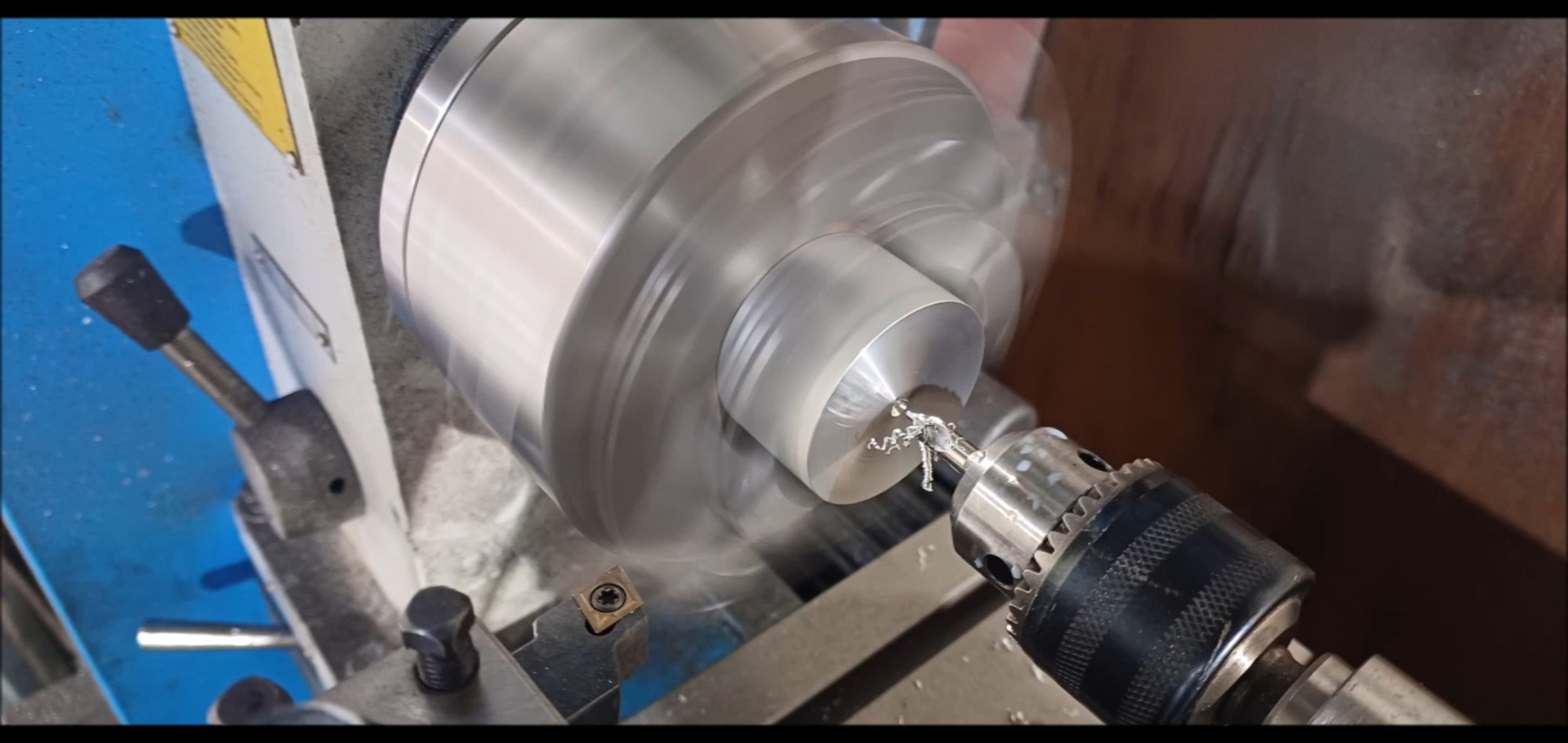

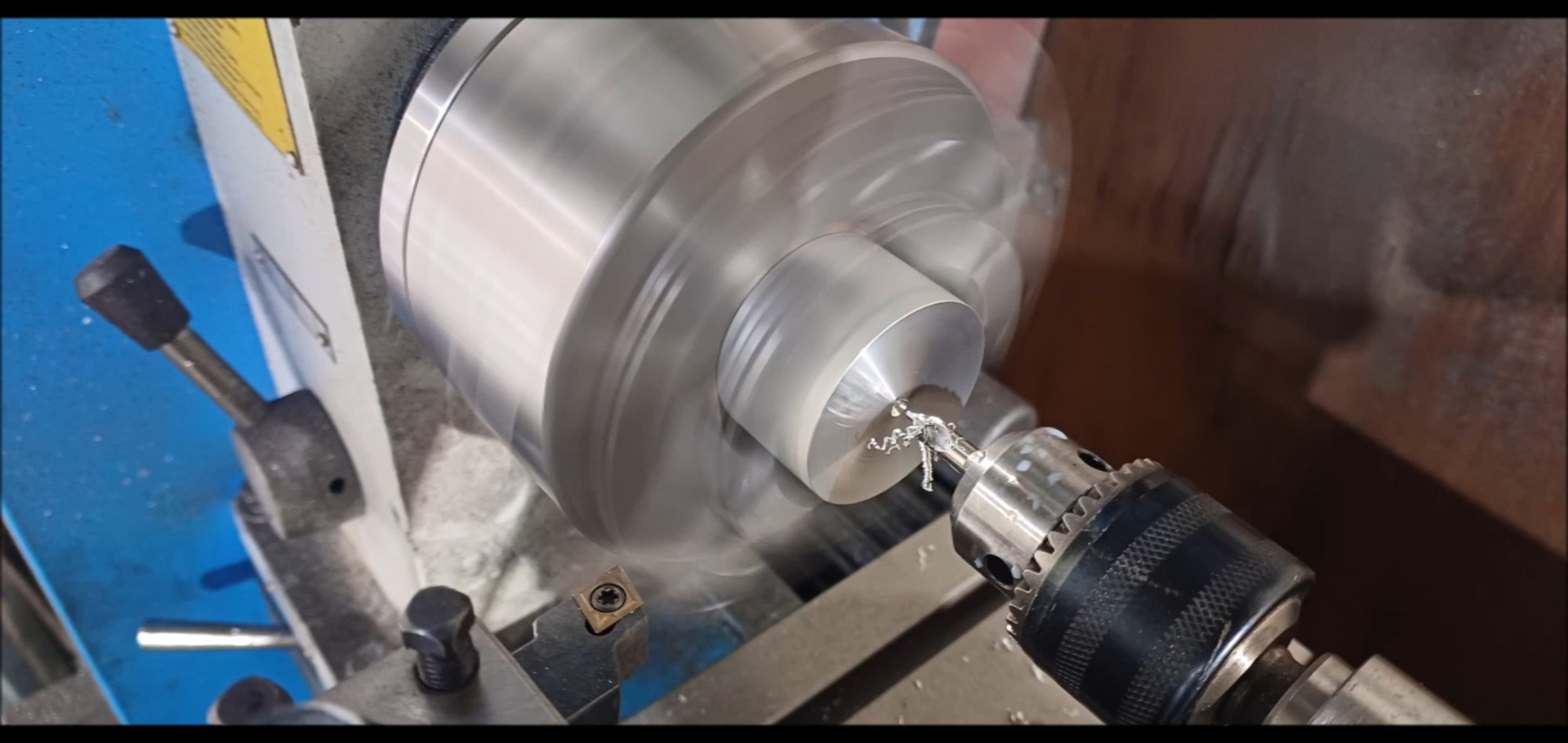

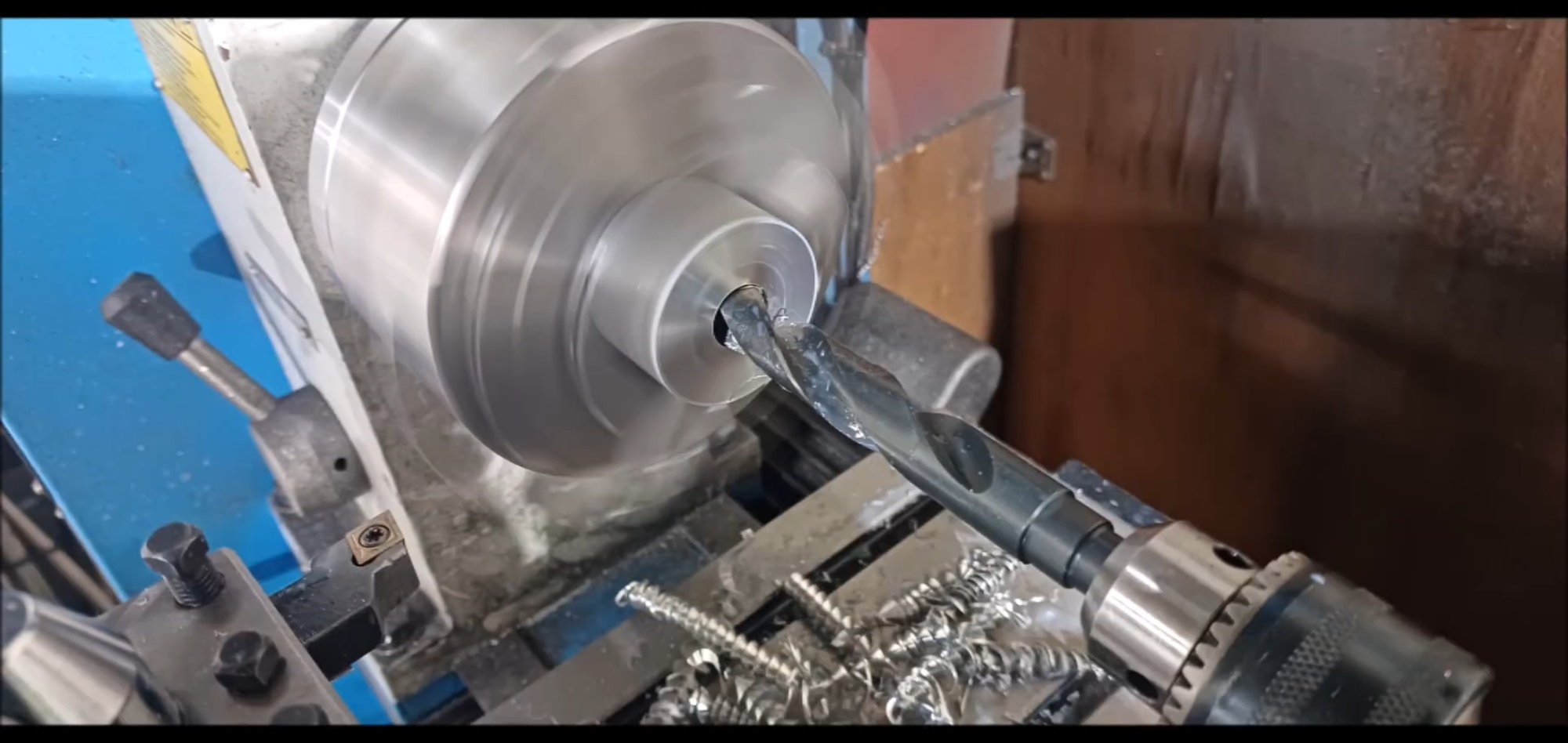

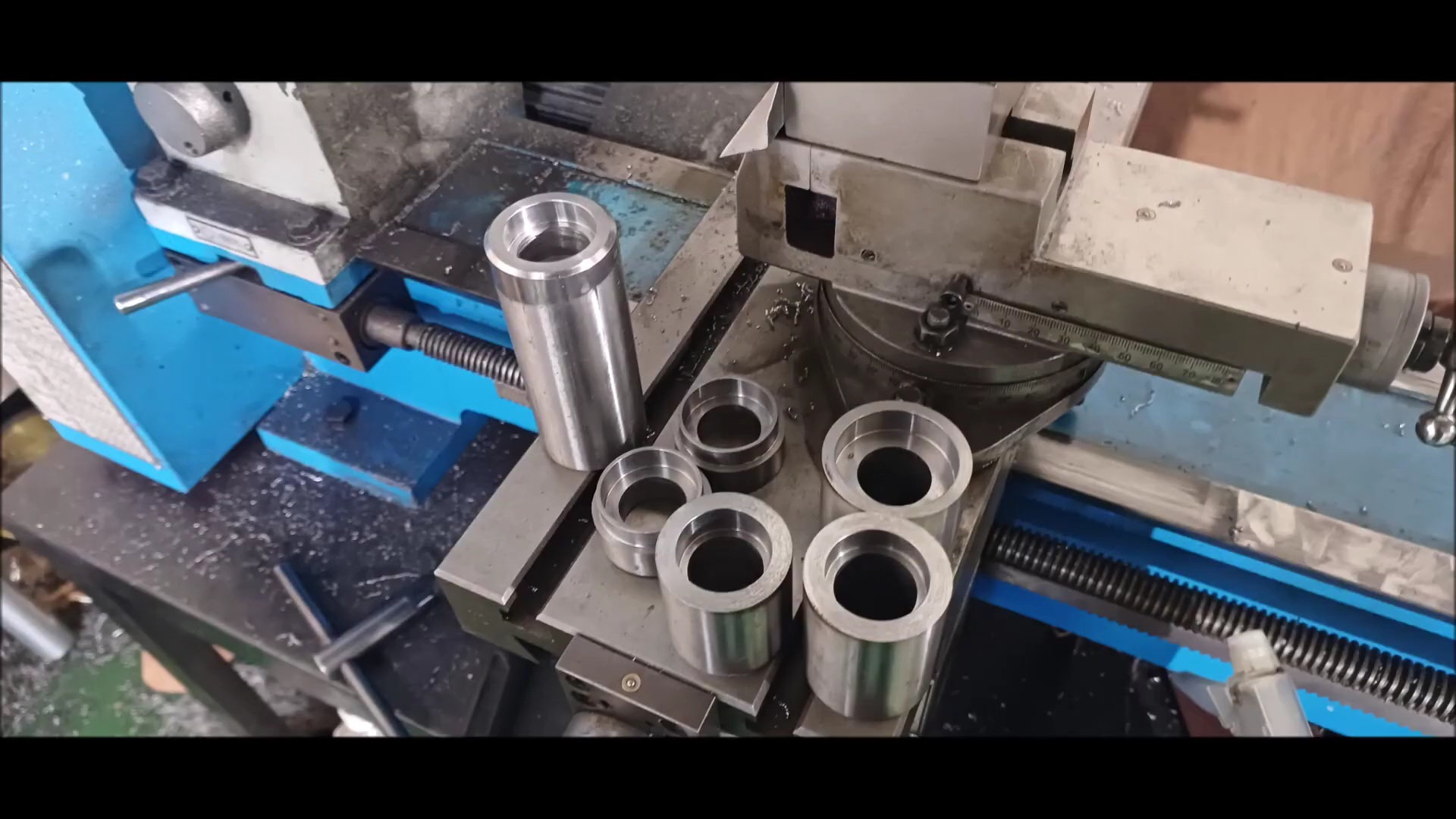

Connecting joint lathe processing

Smaller hole than bearing inner diameter

Hole work completed

Hole operation for bearing fixing

External diameter machining of joint to fit the internal diameter of the bogie wheel

Joint shape machining progress

Shelf machine capacity is small, working repeatedly several times

Joint shape machining completed

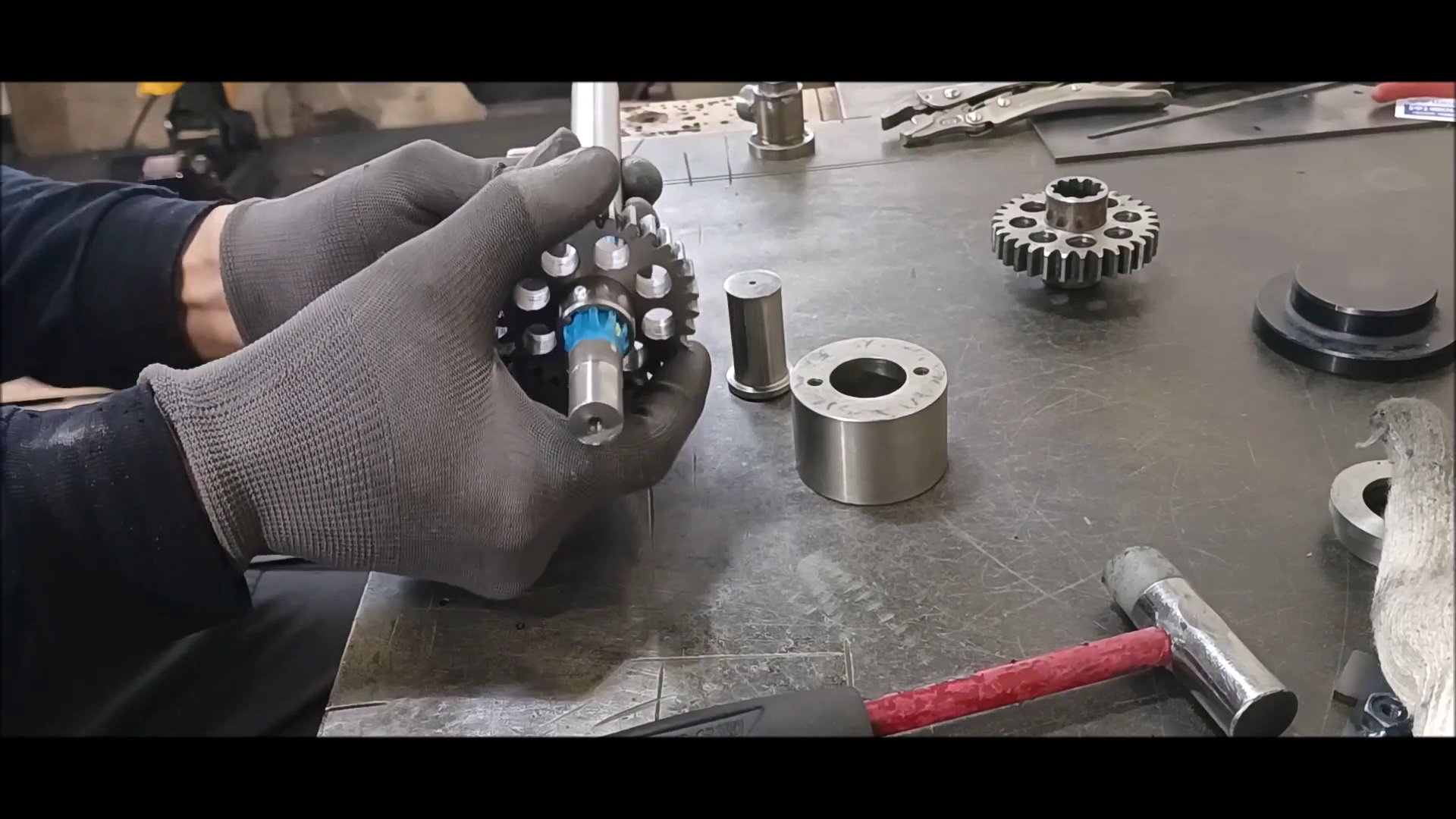

temporary assembly

Joint connection with two bogie wheels, bearing assembly example when installing

Check the clearance of the center guard of the track.

Prepare the flanges for hole work to match the bogie wheels.

Continued in the next episode

Regards,

Young

Bogie Wheel Work Continues Last Week

Install spokes on the viewing wheel

Spoke operation completed

Create detailed parts with 3D printers

Identical drive wheel cover

Flanges to secure the same drive wheel cover

Remove the burrs on the rear of the bogie wheel with a hand grater.

Finish with a flat grinder

The sharp edges go smoothly, too.

Completing the grinder operation

Stand by for next action

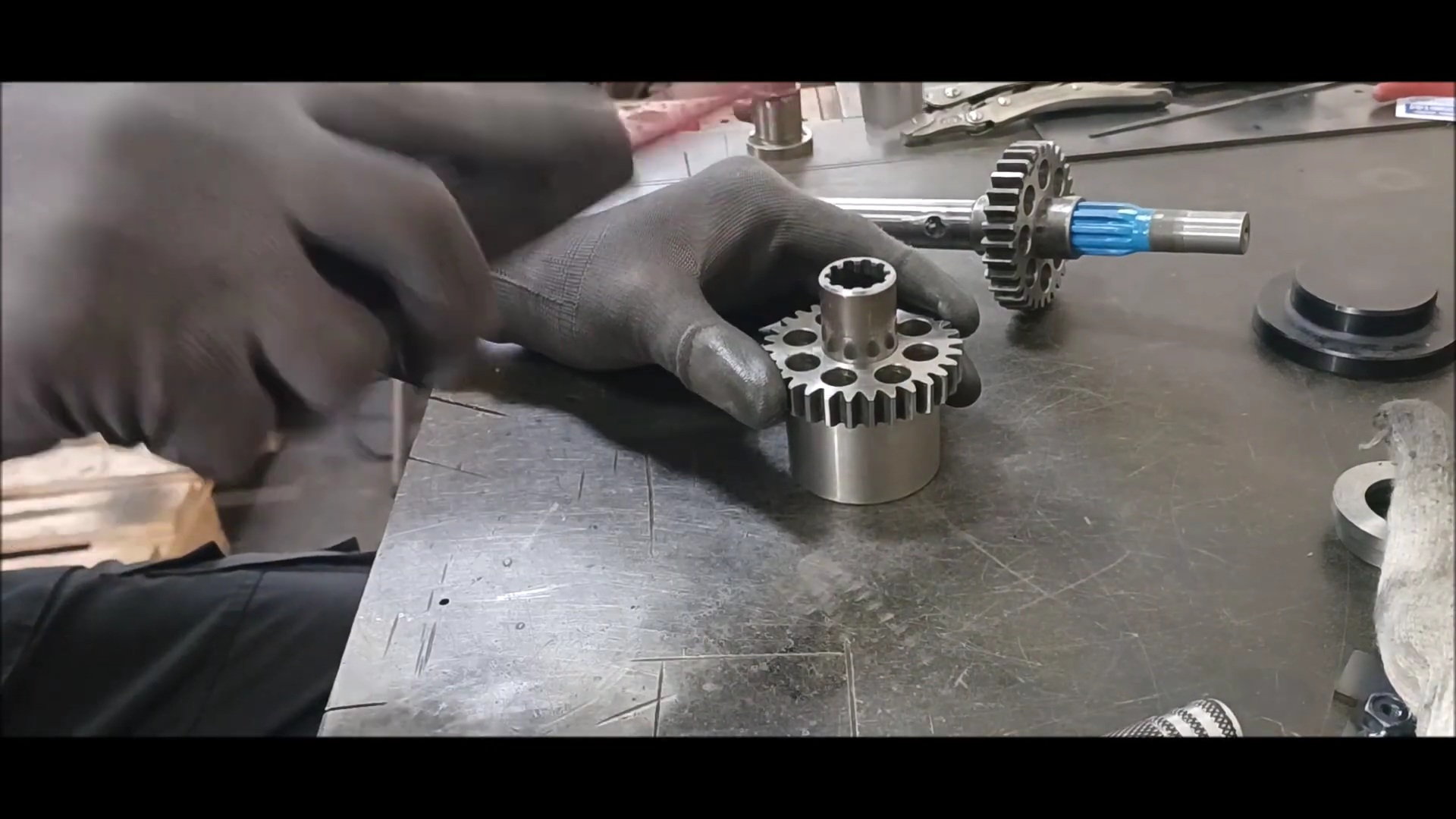

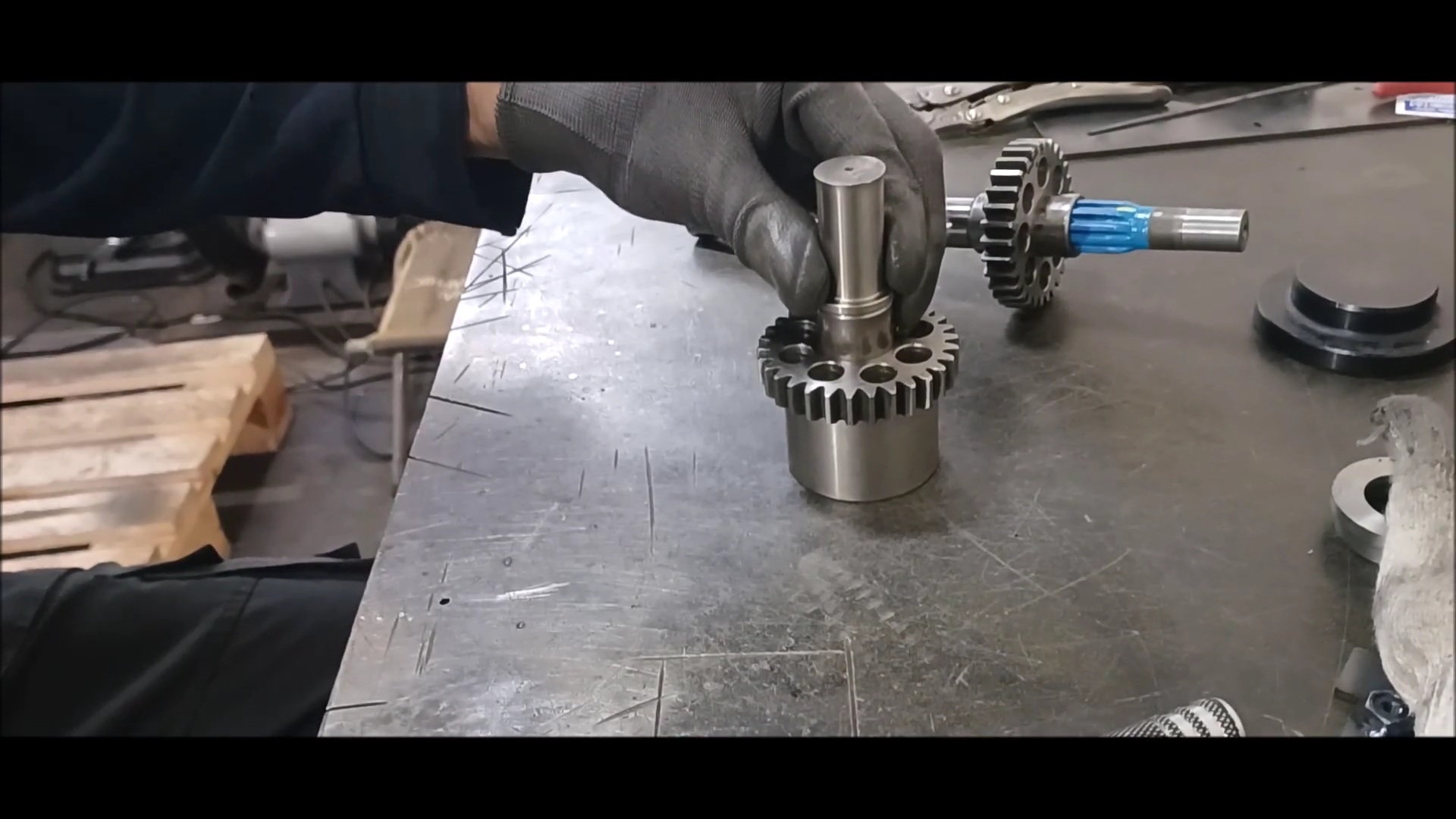

Connecting joint lathe processing

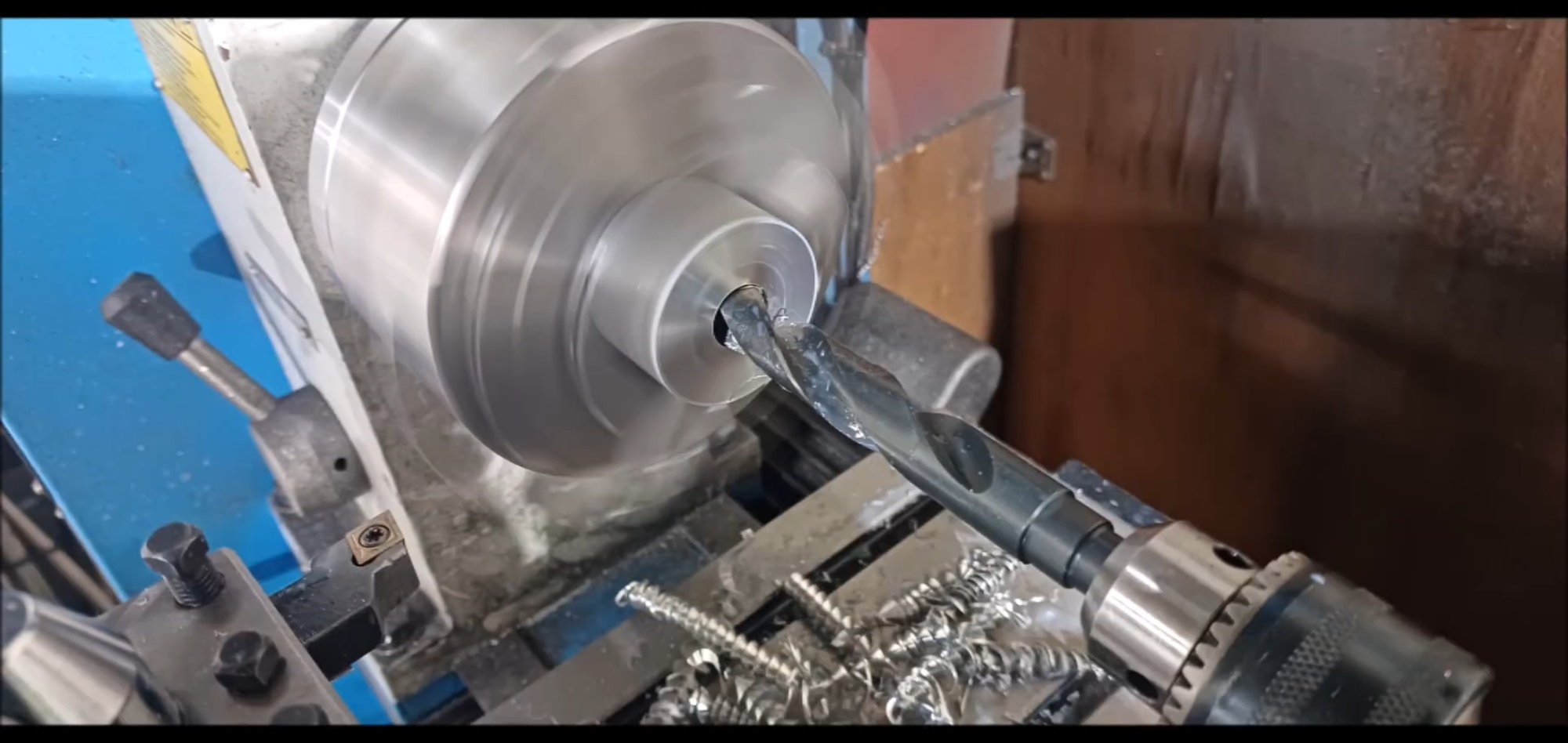

Smaller hole than bearing inner diameter

Hole work completed

Hole operation for bearing fixing

External diameter machining of joint to fit the internal diameter of the bogie wheel

Joint shape machining progress

Shelf machine capacity is small, working repeatedly several times

Joint shape machining completed

temporary assembly

Joint connection with two bogie wheels, bearing assembly example when installing

Check the clearance of the center guard of the track.

Prepare the flanges for hole work to match the bogie wheels.

Continued in the next episode

The following users liked this post:

tankme (03-19-2023)

#30

Thread Starter

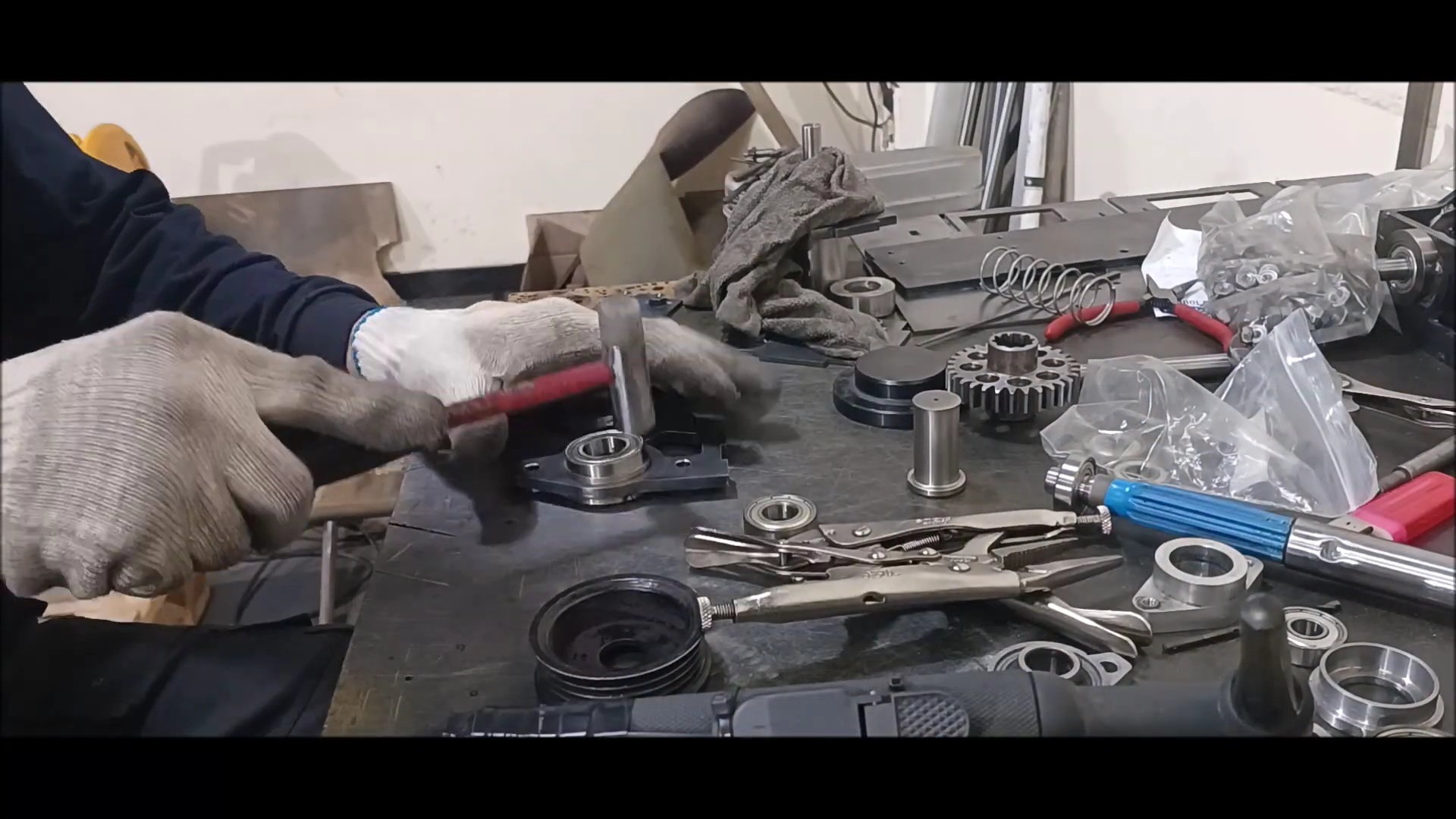

This episode was continued in the last episode with bogie wheel work.

The thickness of the bogie wheel of the 2023 K2 Black Panther (ic2504) is 1 mm thicker than that of 2022, and the shaft cover also runs with the bogie wheel.

Regards,

Young

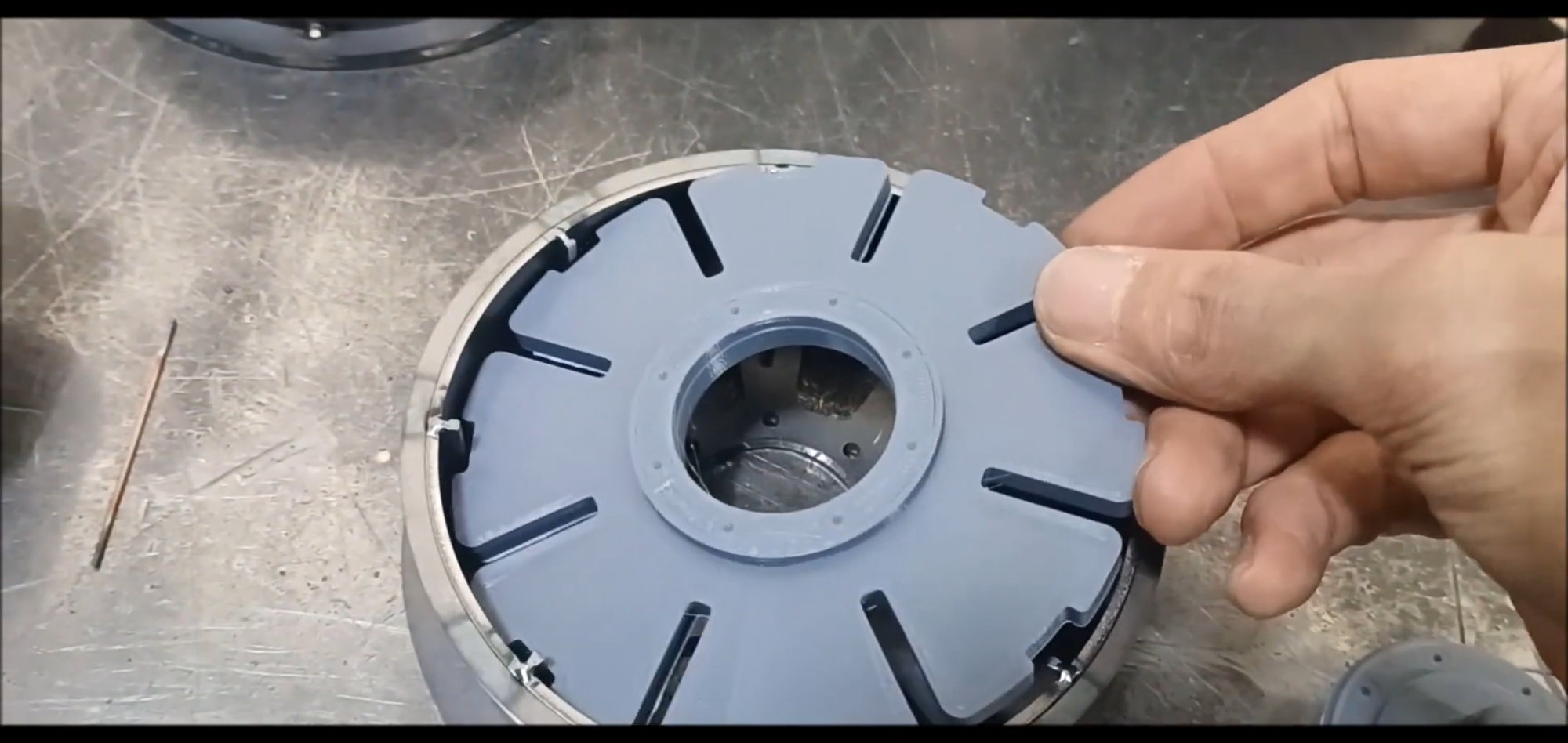

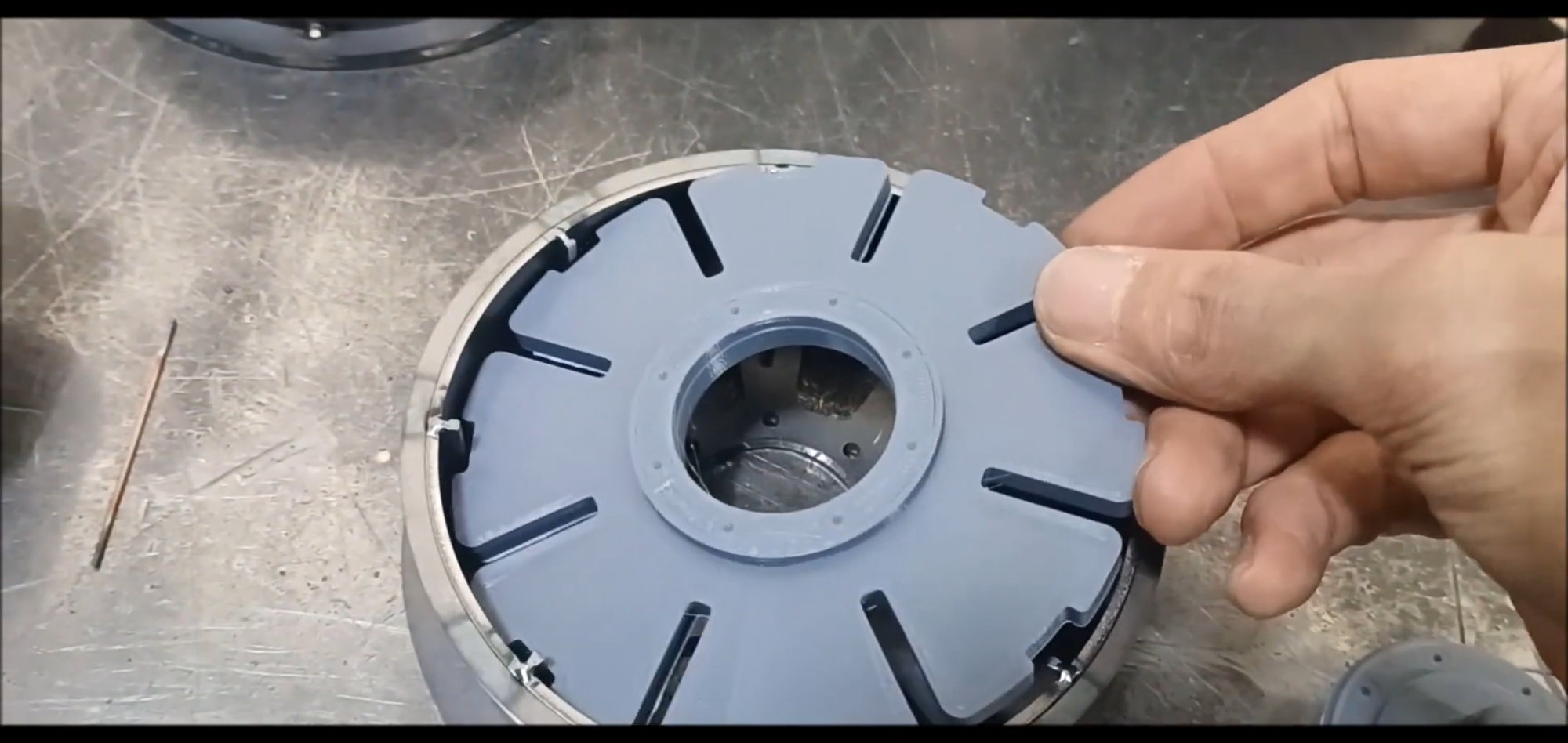

A bogie wheel connection hub created in the last episode.

Temporary fix the bogie wheel and hub with instantaneous adhesive to install bolt holes in the flange of the bogie wheel connection hub.

Press by hand for a while while the instantaneous adhesive hardens.

Temporary connection of the viewing wheel to the hub

Do the reference work on the flange of the hub to drill holes.

Bogie wheel connection hub with reference work done

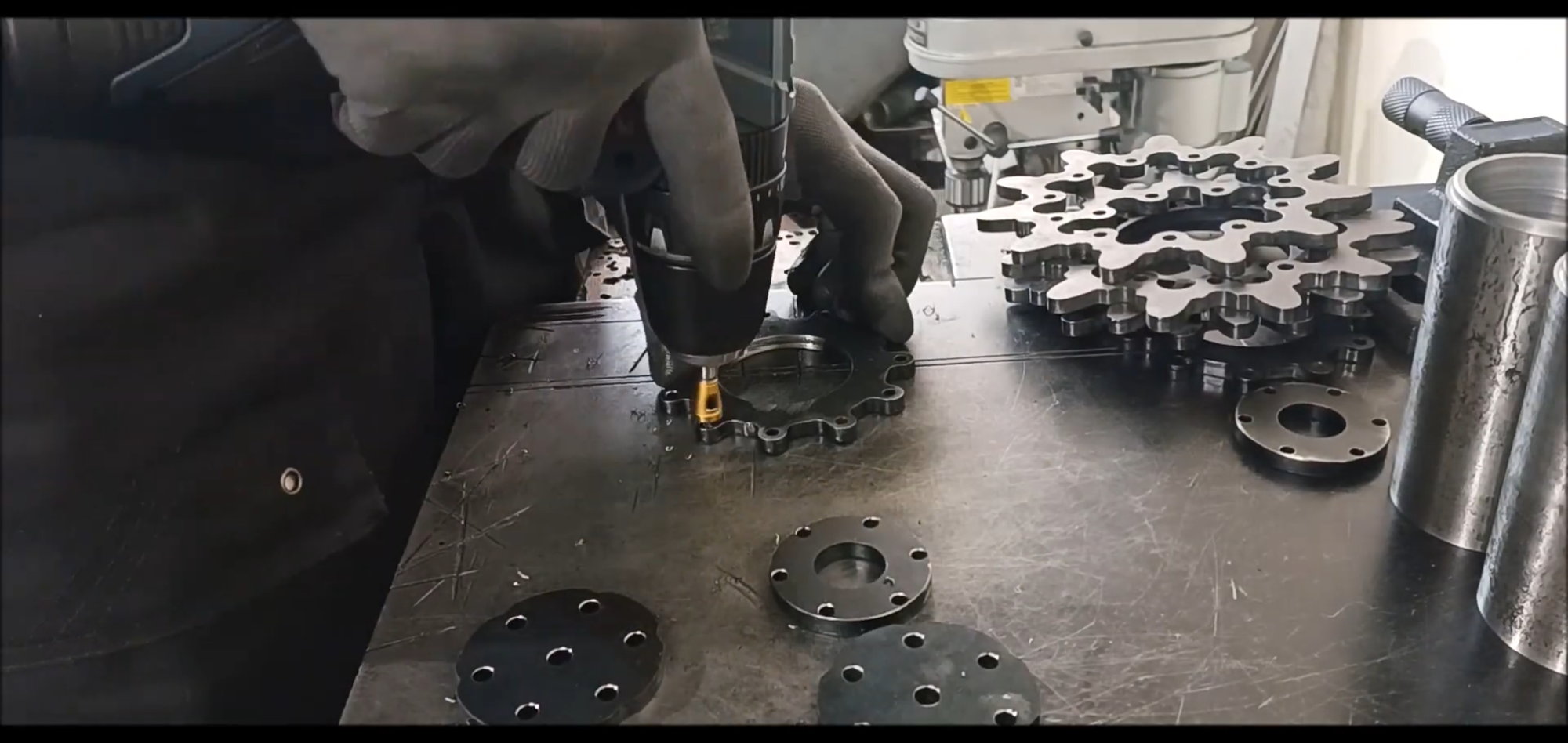

ull-fledged hole work. Use a 3.3 mm drill to allow 3 mm bolts to pass through the hole.

Bogie wheel connection hub with hole work done

Burr must be removed from the flange hole and bearing seating

Since it is made of aluminum, chamfer work or burr removal is simply done with a cutter, not with a shelf machine

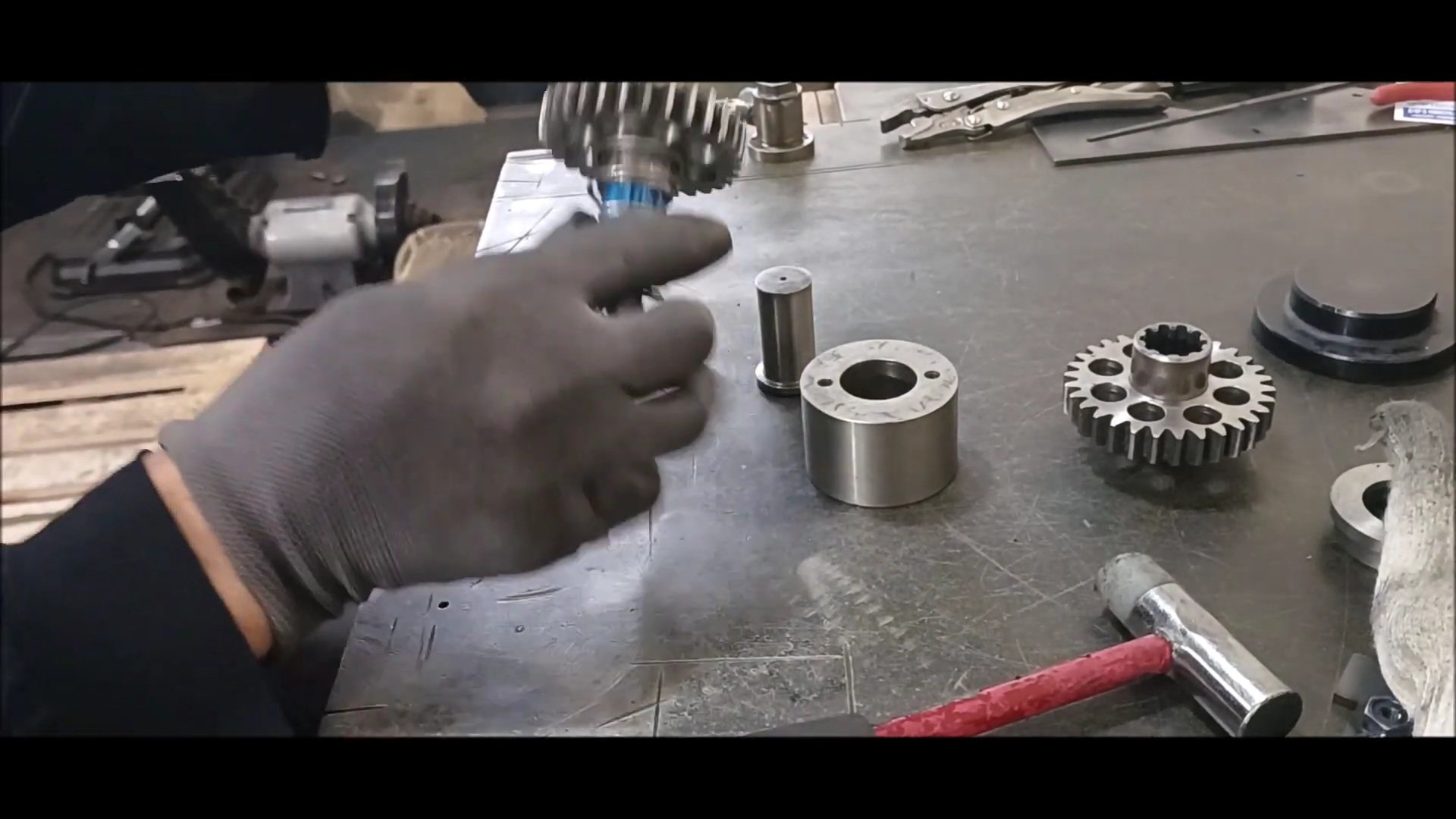

Bearings prepared for the next process

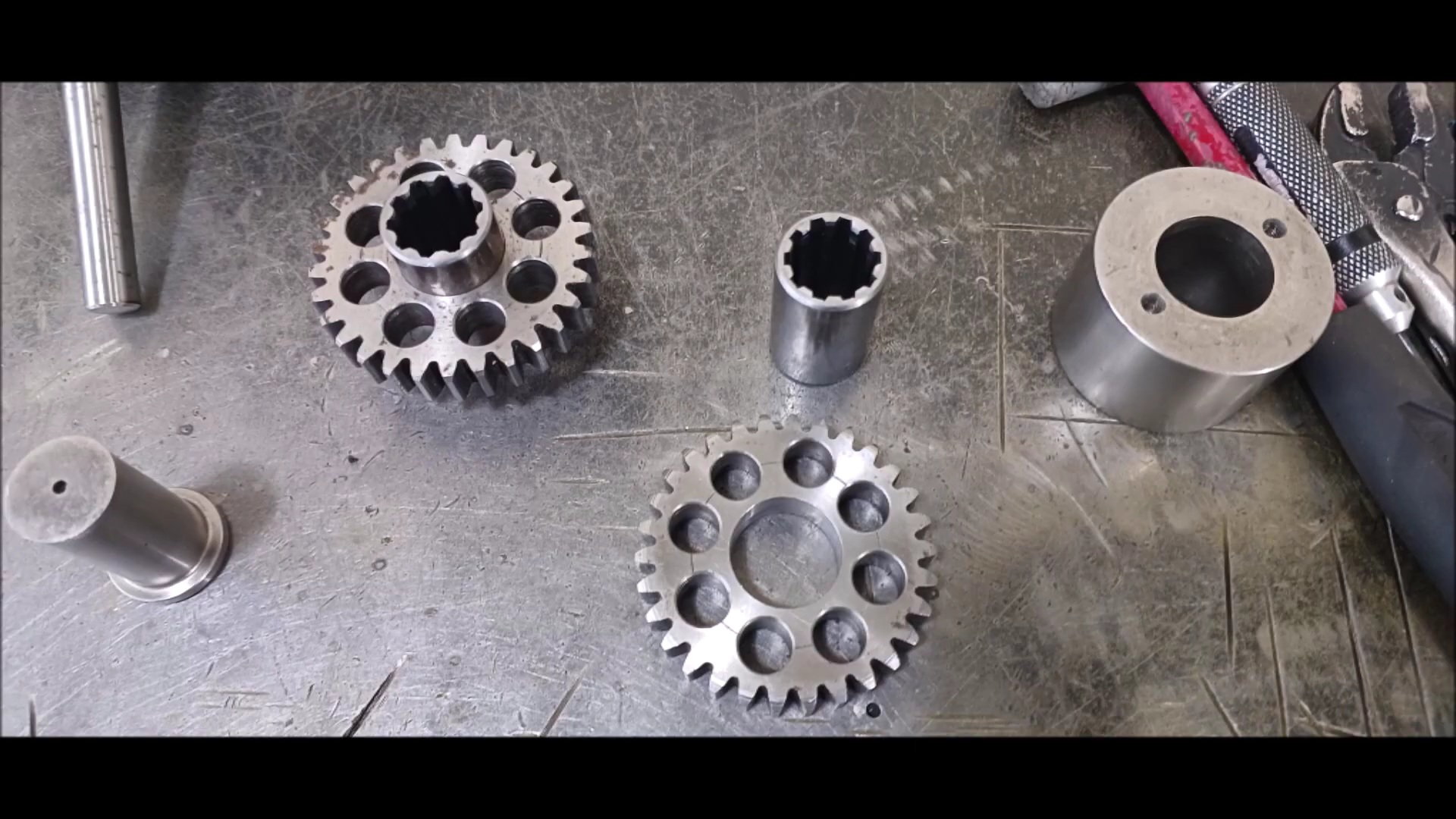

Retainer seal and gears prepared for the next process

Hydraulic drive motor

Hydraulic drive pump

A spring for neutral gears

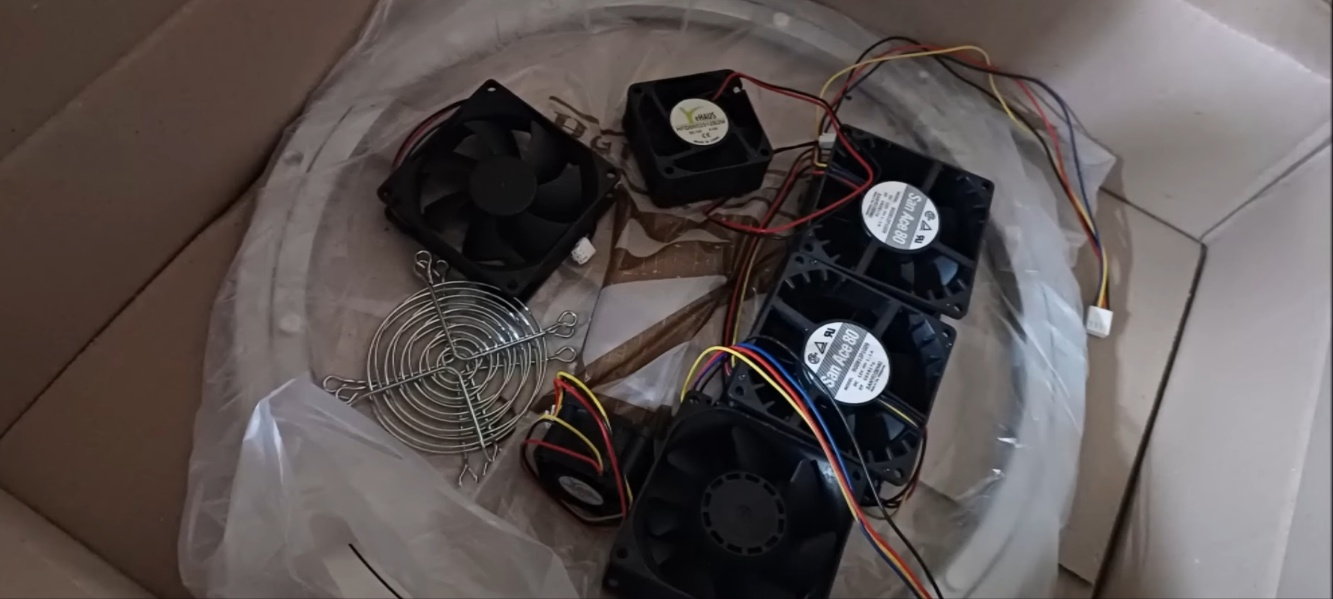

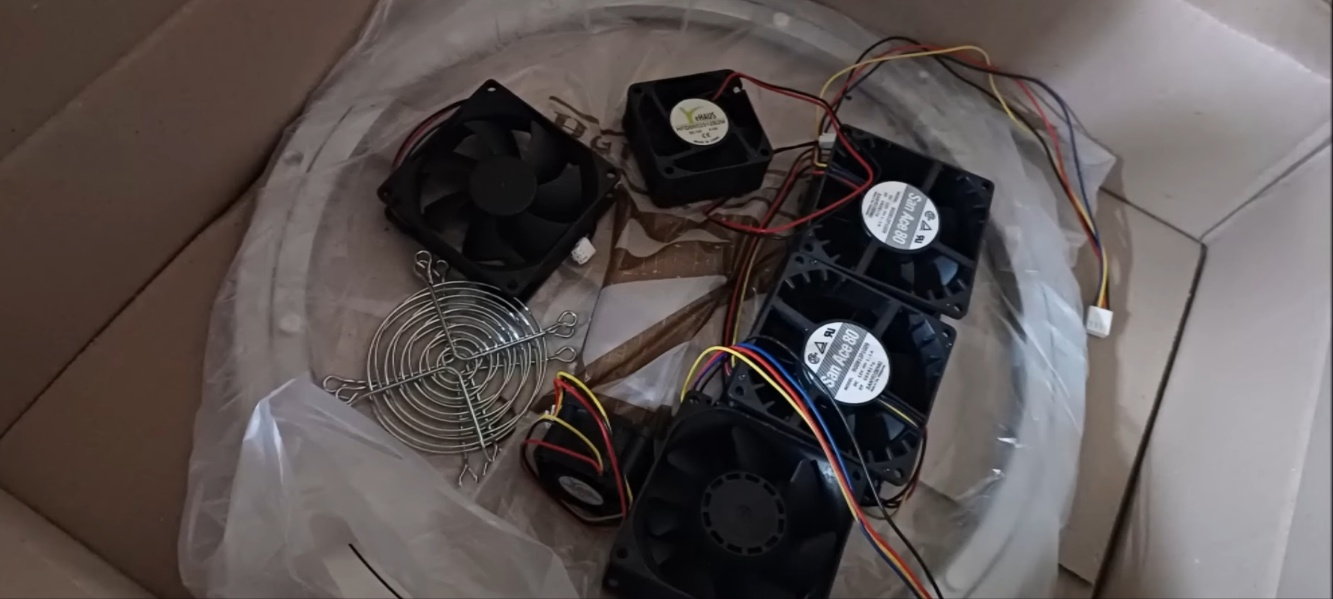

Turret gear and cooling fans

Insert bearing into bogie wheel connection hub

lattening the bearing insertion operation in the bogie wheel connection hub

Bearing inserted bogie wheel connection hub

Bearing Shaft Insertion Test

Sample assembly for bogie wheel centering inspection

mporary tightening of bolts and nuts for sample assembly for bogie wheel centering inspection

The bogie wheel was combined with the shaft and rotated to confirm that it worked very well

3D sculptures and shaft covers to be used on the inside of the bogie wheel

In the next episode, there will be a drive wheel operation

In the next episode......

The thickness of the bogie wheel of the 2023 K2 Black Panther (ic2504) is 1 mm thicker than that of 2022, and the shaft cover also runs with the bogie wheel.

Regards,

Young

A bogie wheel connection hub created in the last episode.

Temporary fix the bogie wheel and hub with instantaneous adhesive to install bolt holes in the flange of the bogie wheel connection hub.

Press by hand for a while while the instantaneous adhesive hardens.

Temporary connection of the viewing wheel to the hub

Do the reference work on the flange of the hub to drill holes.

Bogie wheel connection hub with reference work done

ull-fledged hole work. Use a 3.3 mm drill to allow 3 mm bolts to pass through the hole.

Bogie wheel connection hub with hole work done

Burr must be removed from the flange hole and bearing seating

Since it is made of aluminum, chamfer work or burr removal is simply done with a cutter, not with a shelf machine

Bearings prepared for the next process

Retainer seal and gears prepared for the next process

Hydraulic drive motor

Hydraulic drive pump

A spring for neutral gears

Turret gear and cooling fans

Insert bearing into bogie wheel connection hub

lattening the bearing insertion operation in the bogie wheel connection hub

Bearing inserted bogie wheel connection hub

Bearing Shaft Insertion Test

Sample assembly for bogie wheel centering inspection

mporary tightening of bolts and nuts for sample assembly for bogie wheel centering inspection

The bogie wheel was combined with the shaft and rotated to confirm that it worked very well

3D sculptures and shaft covers to be used on the inside of the bogie wheel

In the next episode, there will be a drive wheel operation

In the next episode......

Last edited by PE YOUNG; 03-27-2023 at 10:28 PM.

#34

Thread Starter

For production inquiries, write to Mr.Shin.

Please feel free to inquire.

Below is his email address.

[email protected]

Please feel free to inquire.

Below is his email address.

[email protected]

Last edited by PE YOUNG; 04-01-2023 at 02:18 AM.

#35

Thread Starter

#36

Thread Starter

From mid-April, K2's work speed seems to be accelerating.

This is because another project is currently underway first and it needs to be finished.

Today's episode

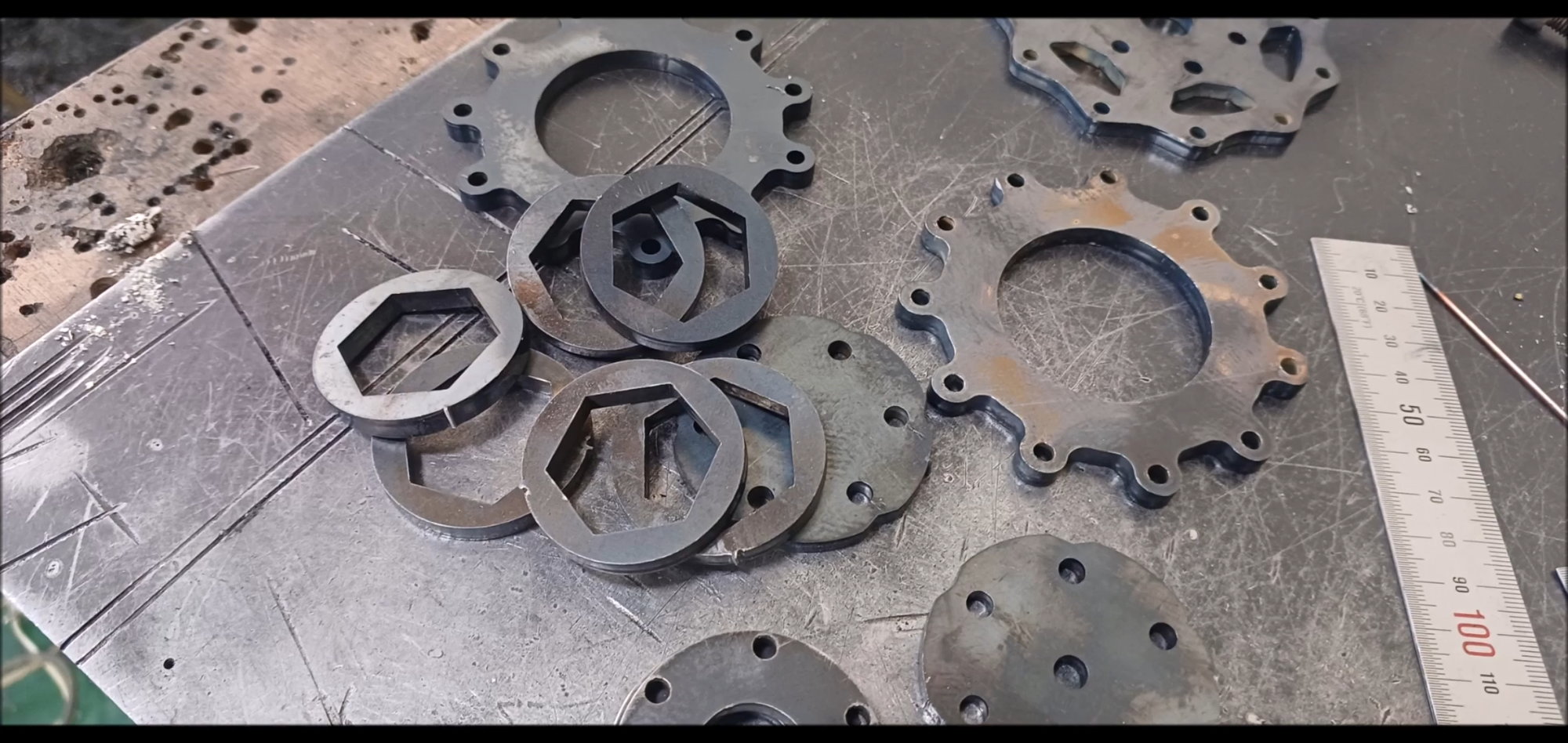

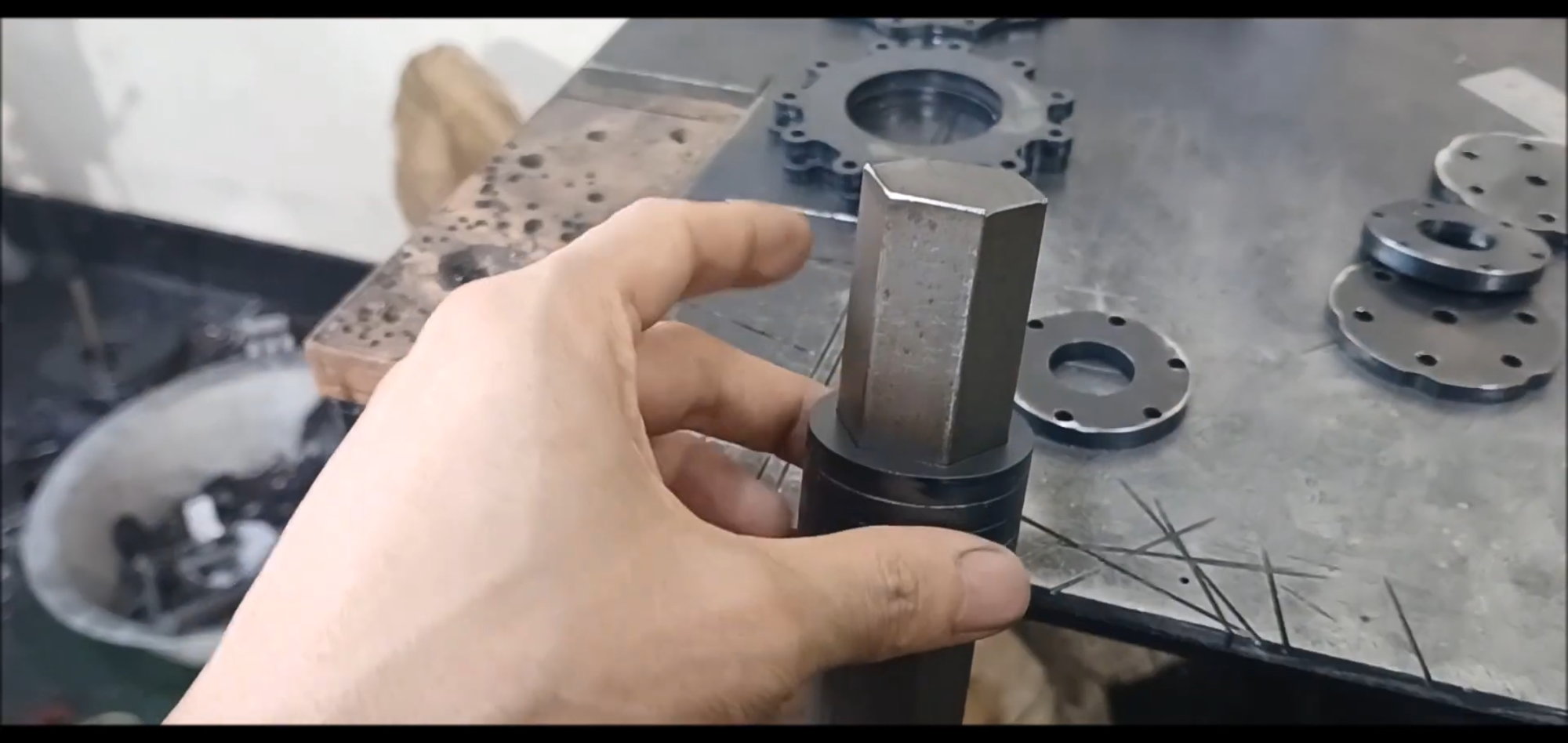

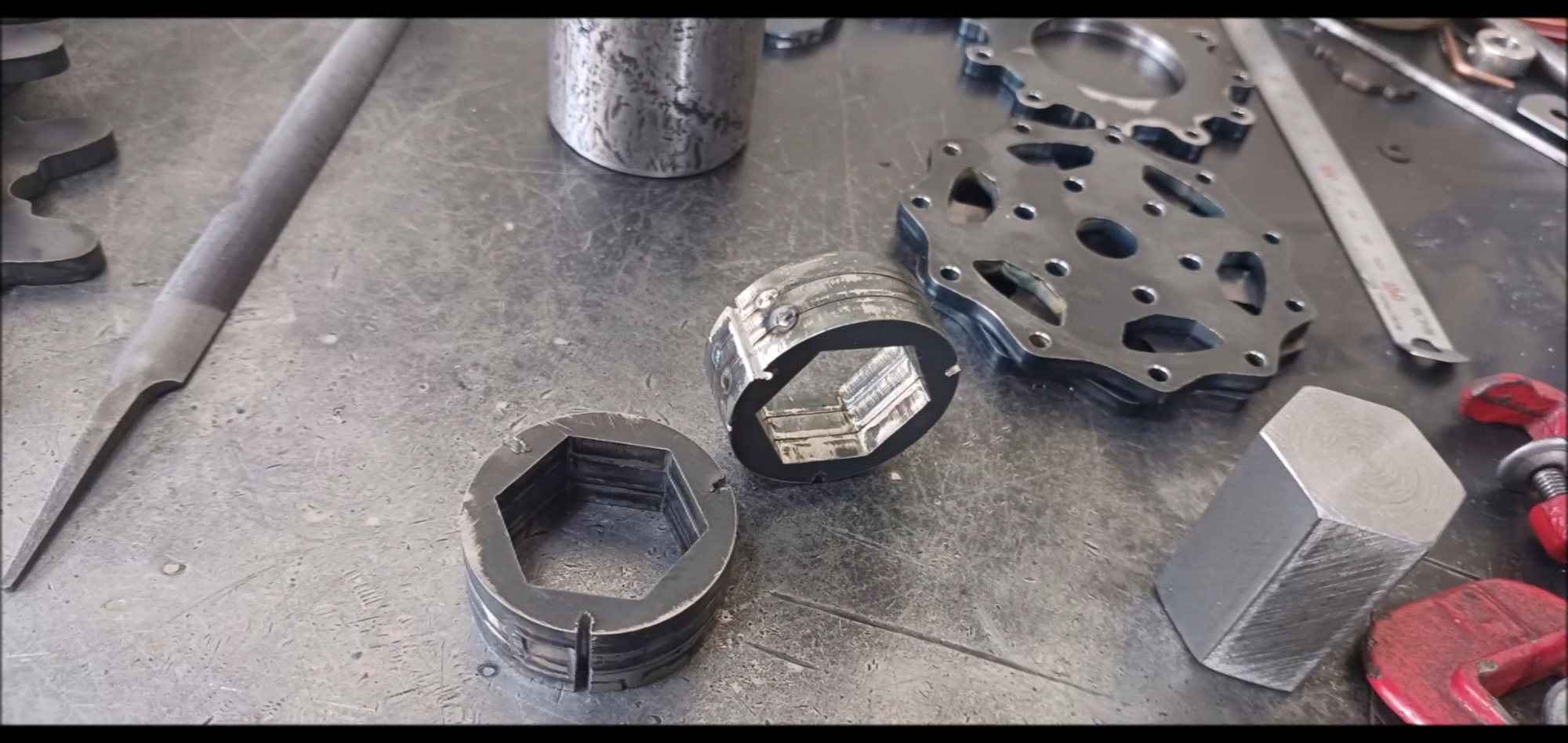

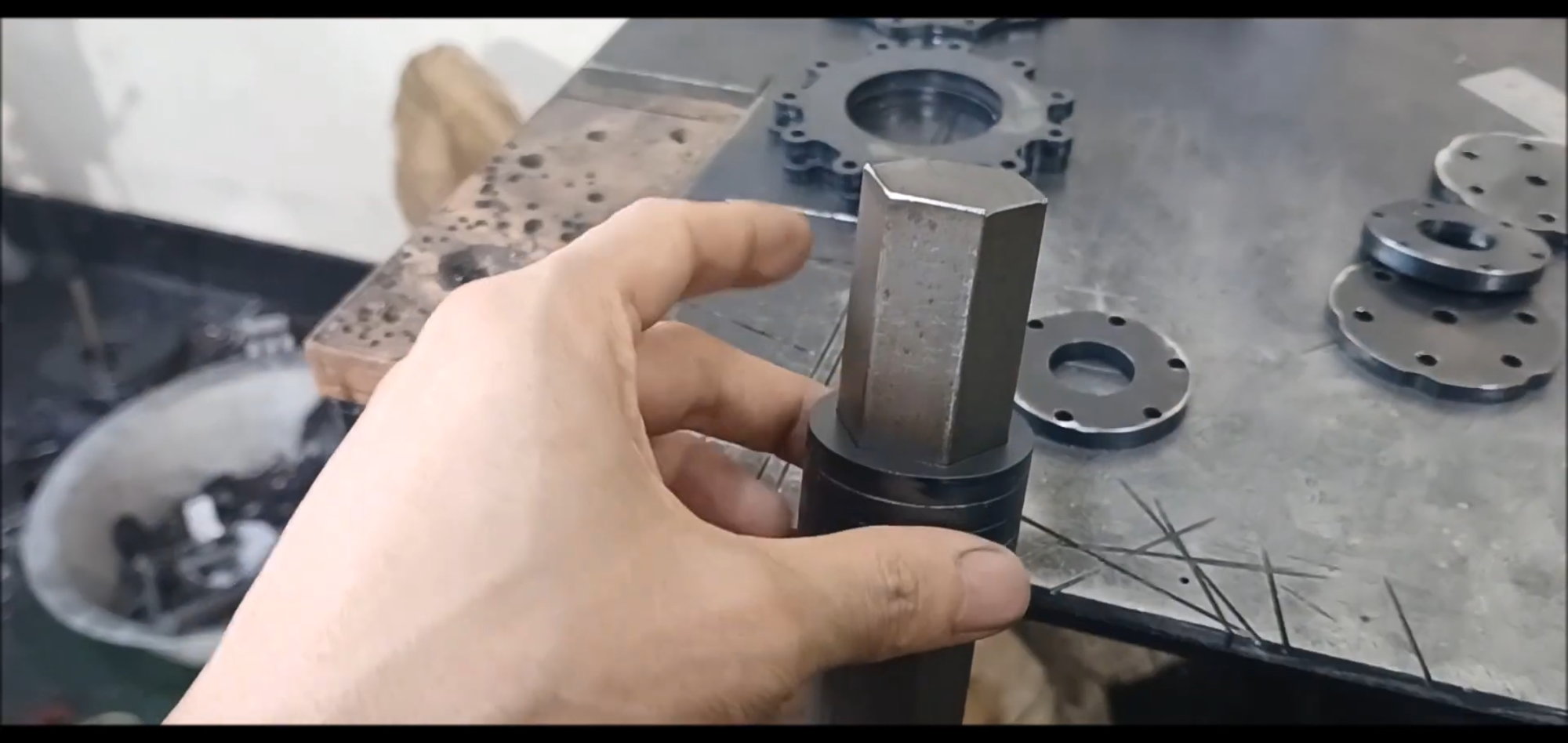

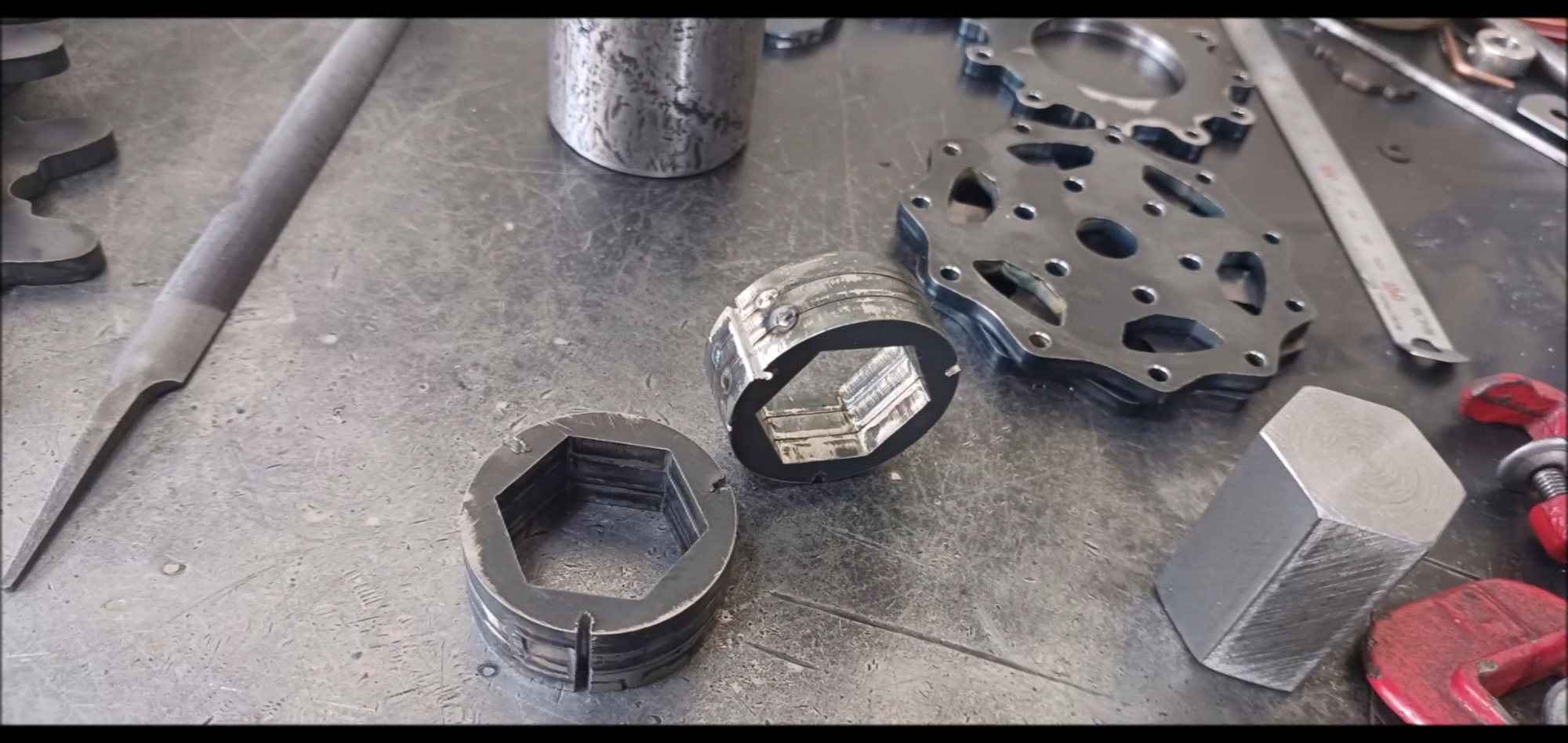

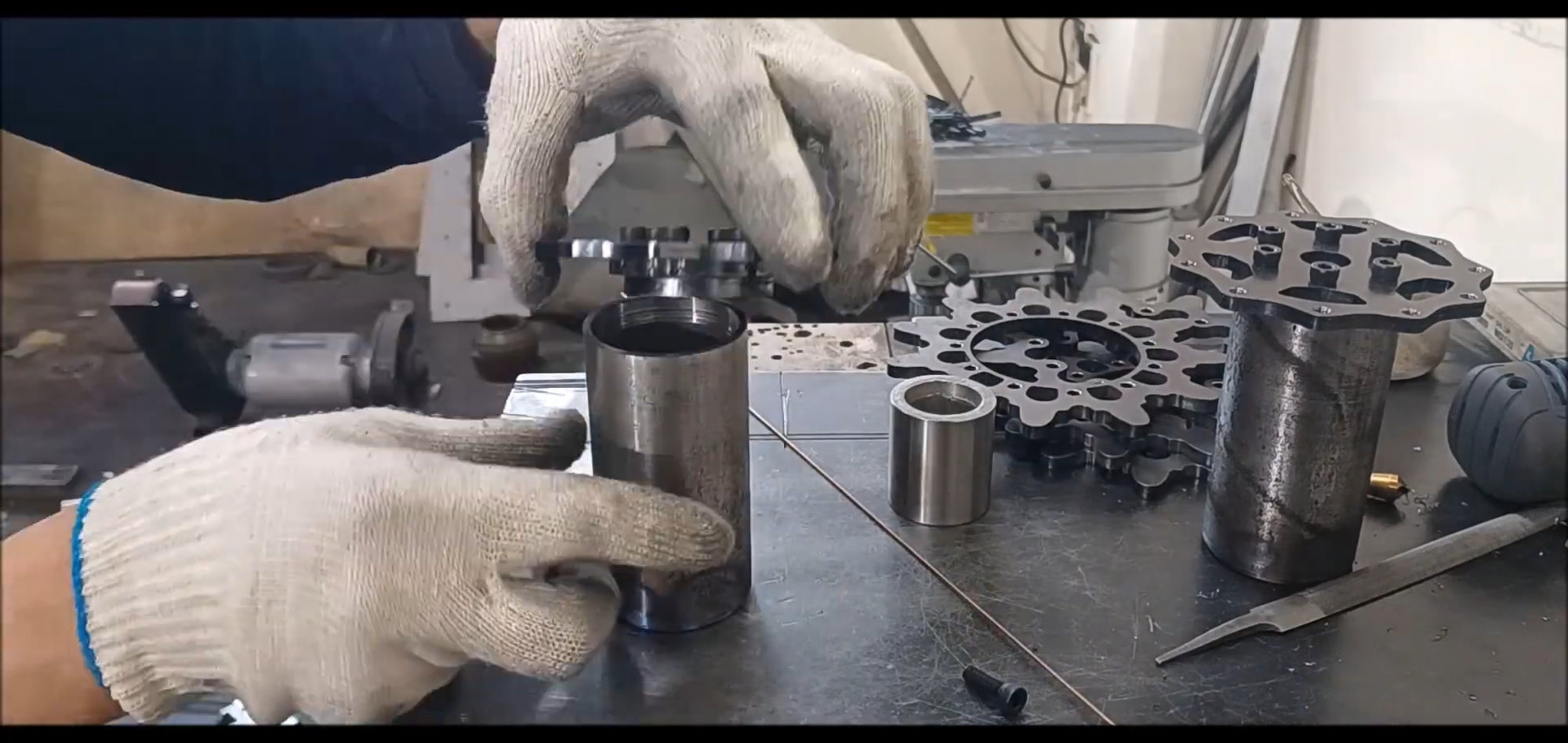

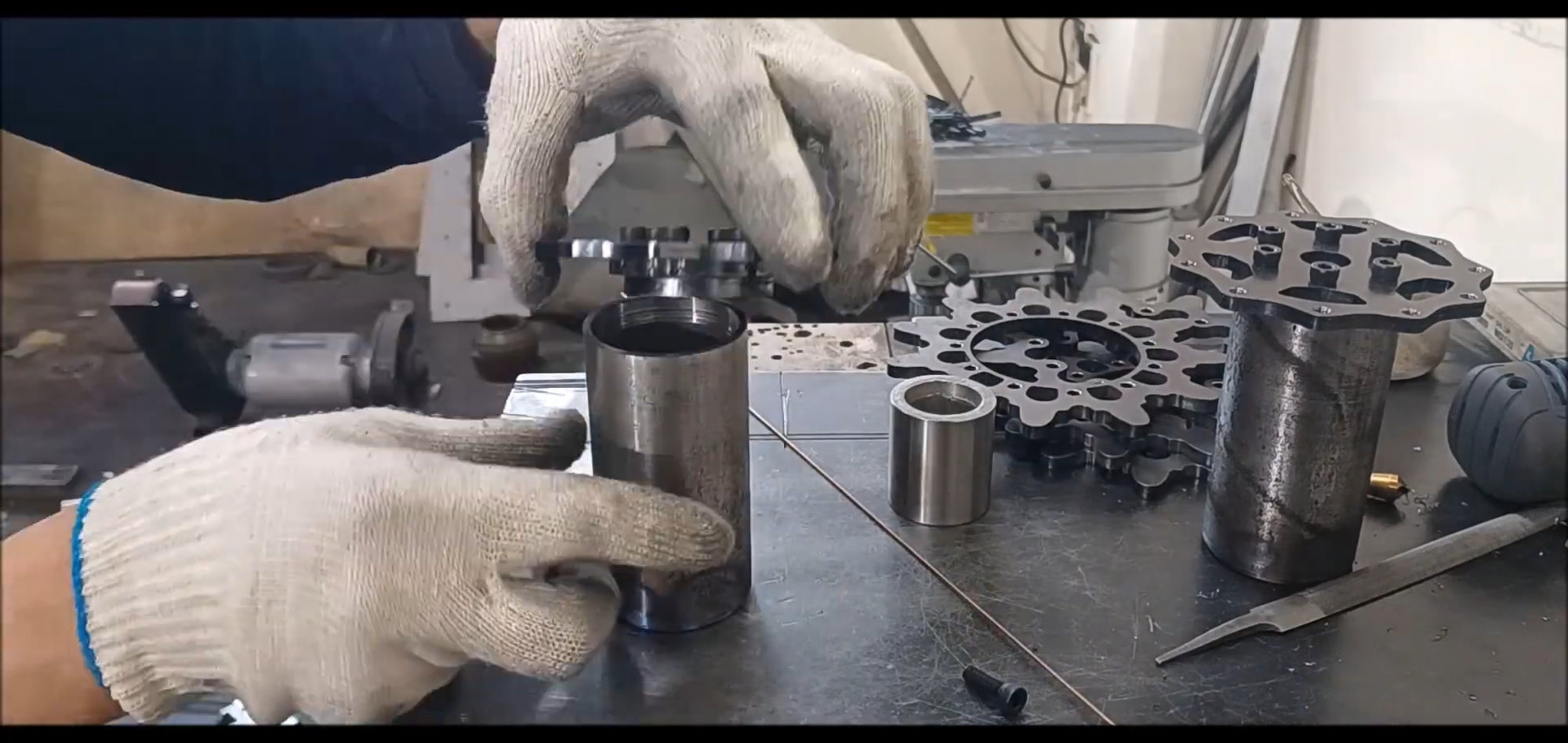

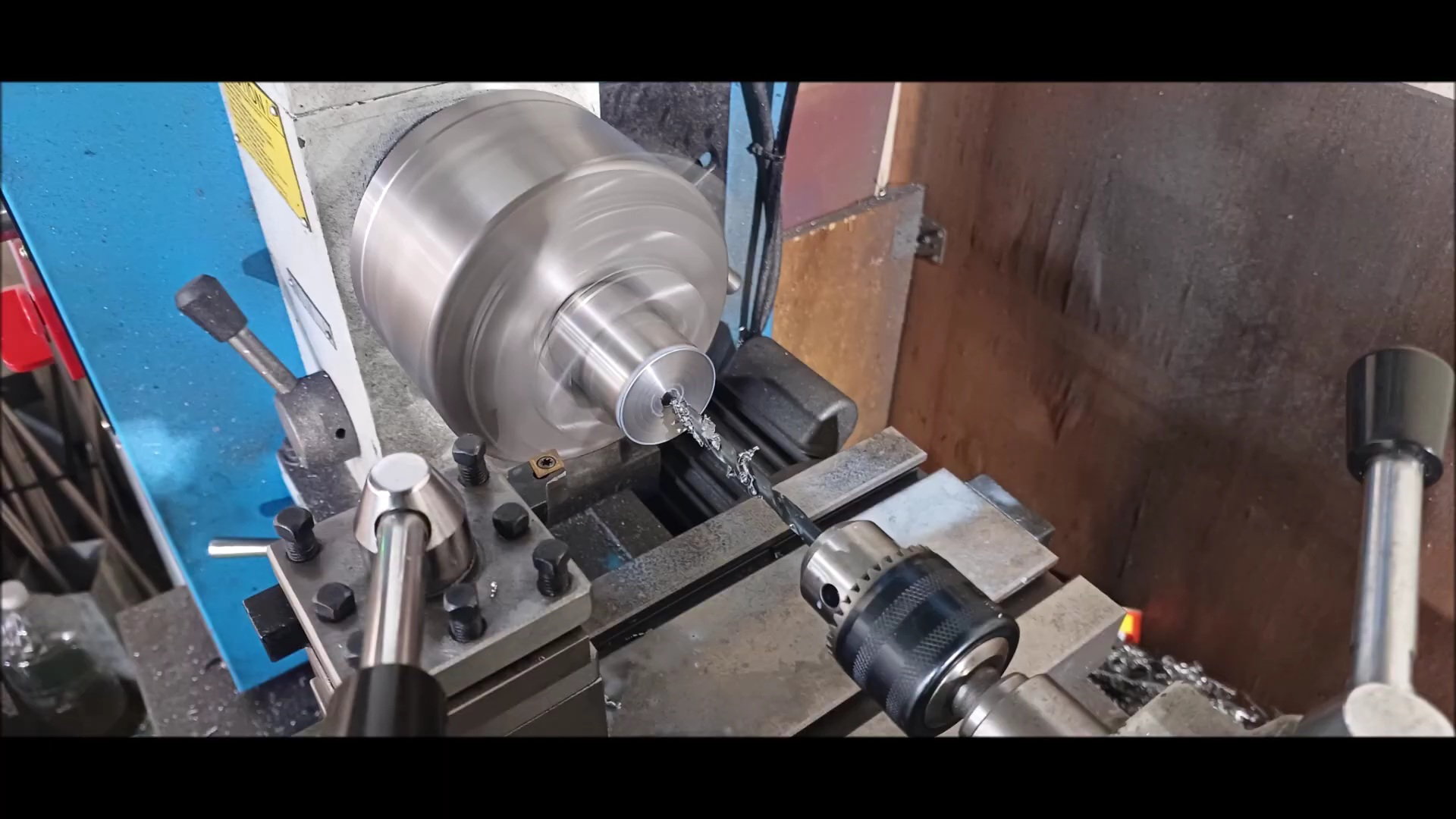

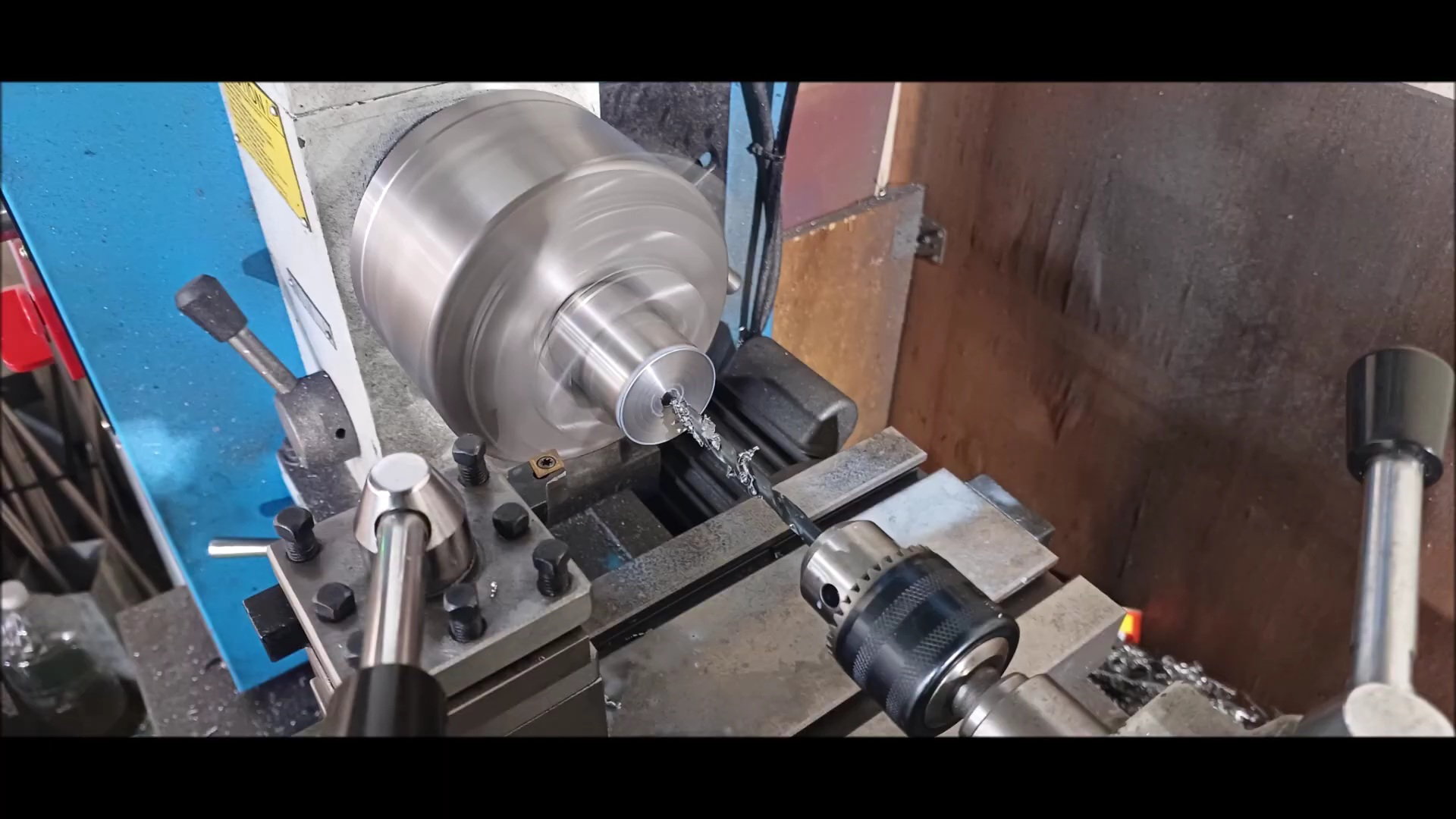

The material required for drive wheel fabrication is mod steel. Prepare two seamless pipes for laser cutting and drive wheel shafts.

The drive shaft is a hexagonal round bar. The inside of the drive wheel and the hexagonal round bar must be connected very precisely. Therefore, the work is carried out by checking the coupler elaborately.

Check the clearance of the hexagonal round bar and coupler.

Finely dig out the inner diameter of the pipe to which the coupler outer diameter is to be seated with a shelf machine.

After machining cylindrical pipes dug to fit the coupler diameter at the depth of the design

The cylindrical pipe inlet outer diameter is also machined to fit the inner diameter of the sprocket wheel

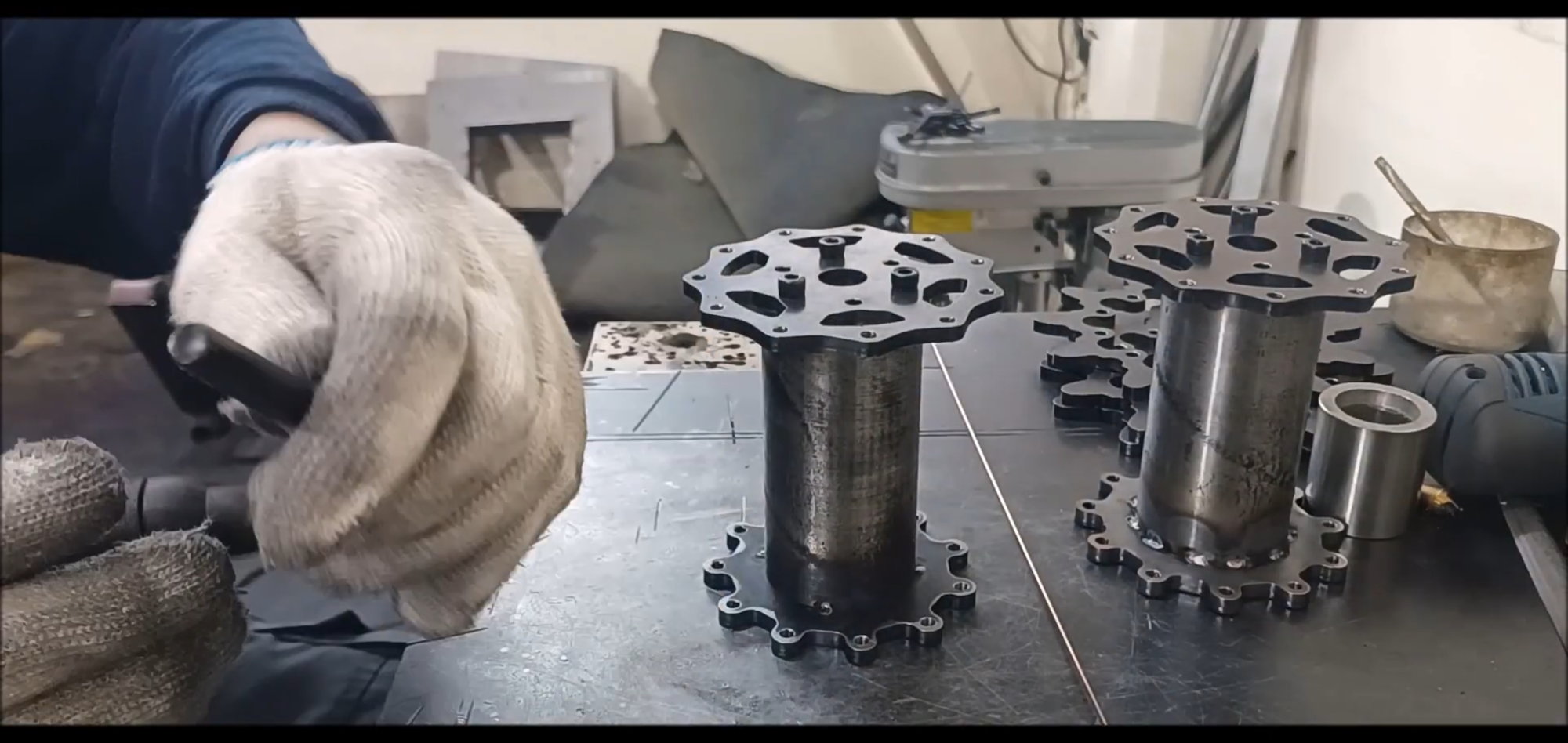

A disk for fixing the sprocket is installed in the pipe opposite to the coupler insertion part

Cylindrical pipe with both ends machined so that both disk and coupler can be inserted

Tap the sprocket connection plate

The disk also works as a tap

Sprocket connection disks also tap

Tap operation is limited to all drive wheel components without omission

Thread work is done on all drive wheel components without omission

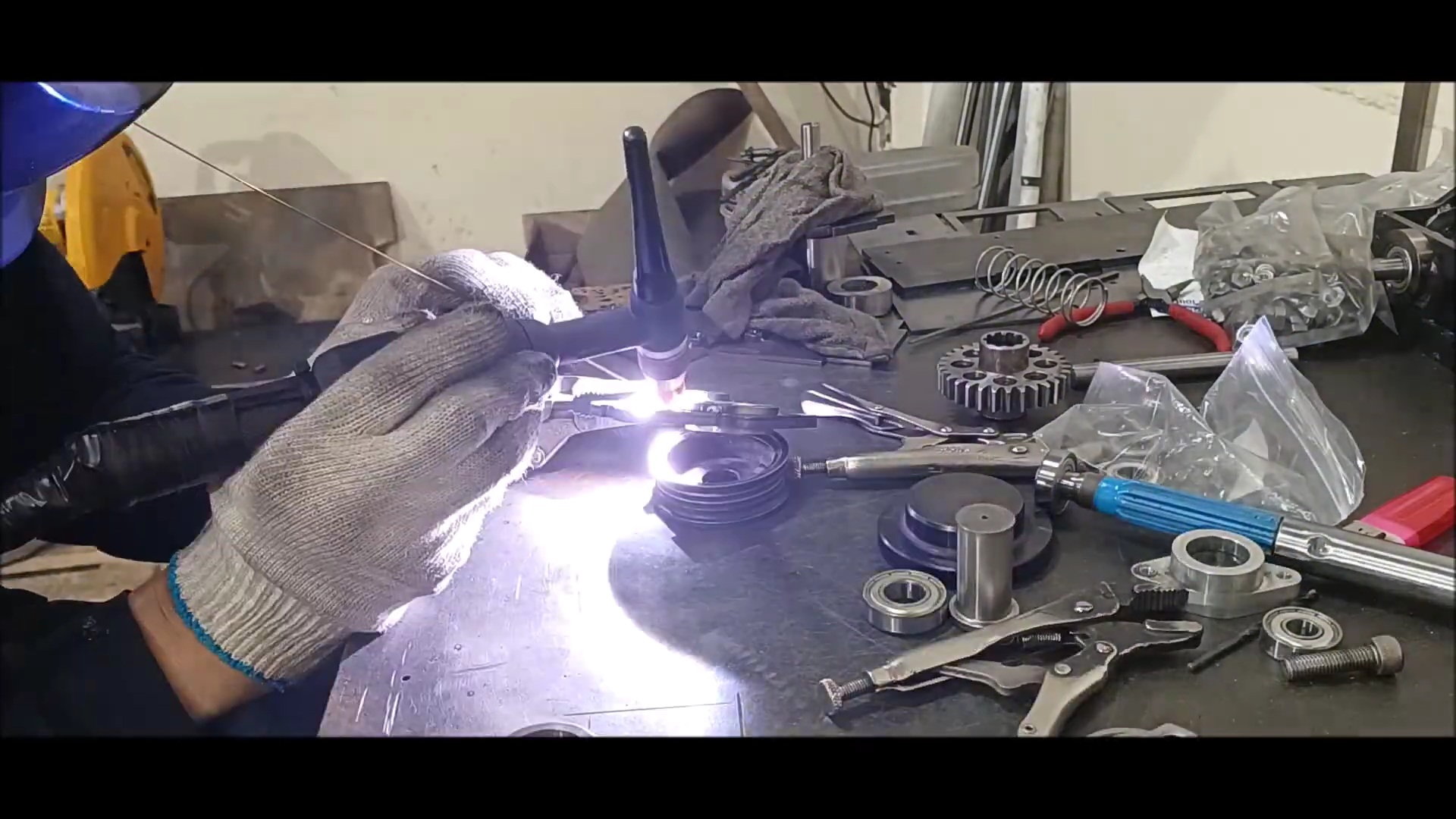

The couplers connected to the hexagonal round bar are welded in three pairs.

Coupler welded with grooves in a straight line

The coupler is welded thickly

Align the coupler and cylinder vertically with each other for welding

Tap Prevents thermal deformation by inserting a piece of hexagonal round bar into the coupler before welding the coupler and the cylinderand align with a small cylindrical pipe

Prevents thermal deformation by inserting a piece of hexagonal ring rod into the coupler before welding the coupler and cylinder

Tig weld the coupling between the coupler and the seal leader

Again, use a small thread reader to heat-deform and hold the deflection

Welded with care for thermal deformation

It's a 360 degree welding

Carefully weld the coupler and cylinder firmly.

Later, the drive shaft to which the hexagonal round bar is coupled is joined in the above shape

will detail the drive wheel operation.

Next time, continuously

Regards,

Young

This is because another project is currently underway first and it needs to be finished.

Today's episode

The material required for drive wheel fabrication is mod steel. Prepare two seamless pipes for laser cutting and drive wheel shafts.

The drive shaft is a hexagonal round bar. The inside of the drive wheel and the hexagonal round bar must be connected very precisely. Therefore, the work is carried out by checking the coupler elaborately.

Check the clearance of the hexagonal round bar and coupler.

Finely dig out the inner diameter of the pipe to which the coupler outer diameter is to be seated with a shelf machine.

After machining cylindrical pipes dug to fit the coupler diameter at the depth of the design

The cylindrical pipe inlet outer diameter is also machined to fit the inner diameter of the sprocket wheel

A disk for fixing the sprocket is installed in the pipe opposite to the coupler insertion part

Cylindrical pipe with both ends machined so that both disk and coupler can be inserted

Tap the sprocket connection plate

The disk also works as a tap

Sprocket connection disks also tap

Tap operation is limited to all drive wheel components without omission

Thread work is done on all drive wheel components without omission

The couplers connected to the hexagonal round bar are welded in three pairs.

Coupler welded with grooves in a straight line

The coupler is welded thickly

Align the coupler and cylinder vertically with each other for welding

Tap Prevents thermal deformation by inserting a piece of hexagonal round bar into the coupler before welding the coupler and the cylinderand align with a small cylindrical pipe

Prevents thermal deformation by inserting a piece of hexagonal ring rod into the coupler before welding the coupler and cylinder

Tig weld the coupling between the coupler and the seal leader

Again, use a small thread reader to heat-deform and hold the deflection

Welded with care for thermal deformation

It's a 360 degree welding

Carefully weld the coupler and cylinder firmly.

Later, the drive shaft to which the hexagonal round bar is coupled is joined in the above shape

will detail the drive wheel operation.

Next time, continuously

Regards,

Young

#37

Thread Starter

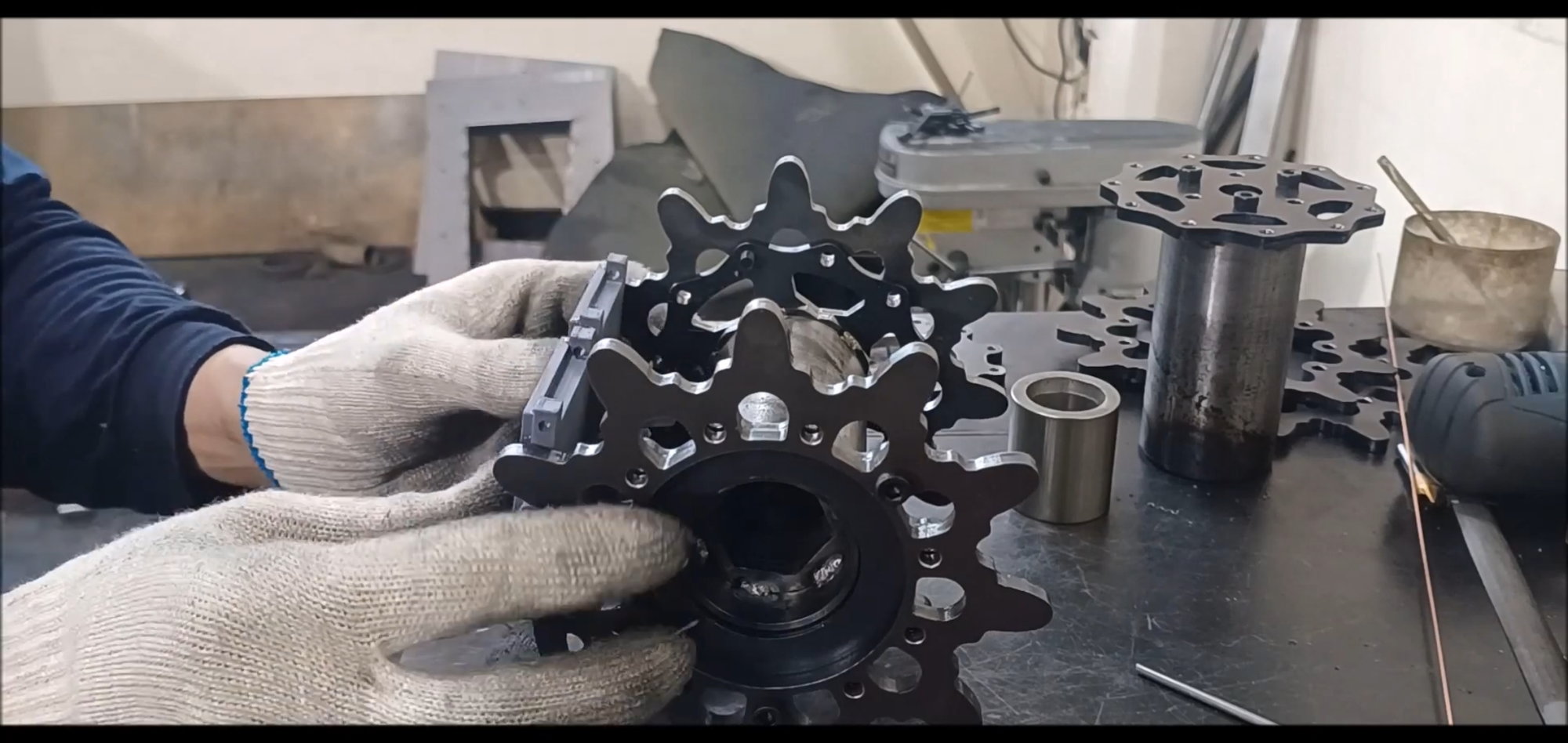

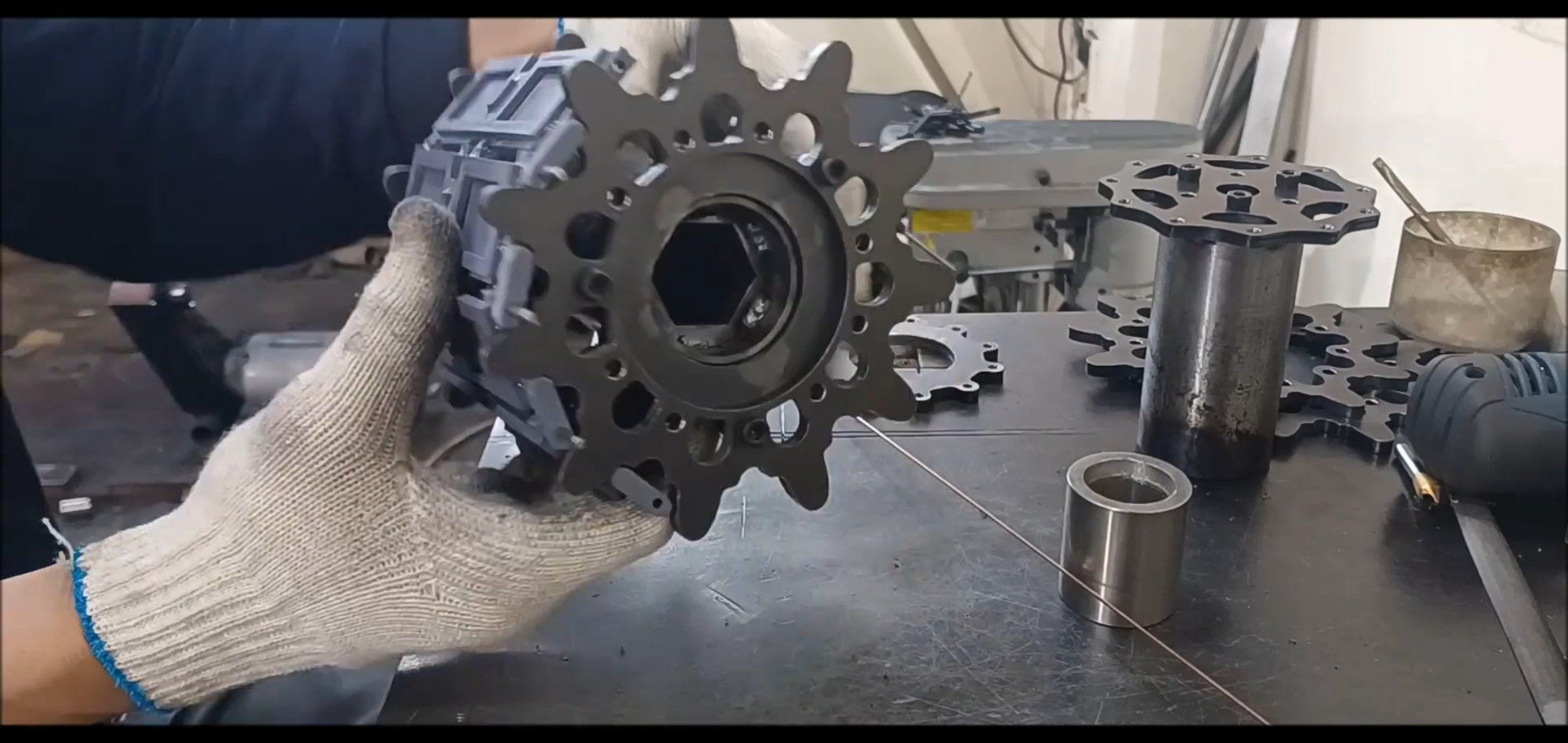

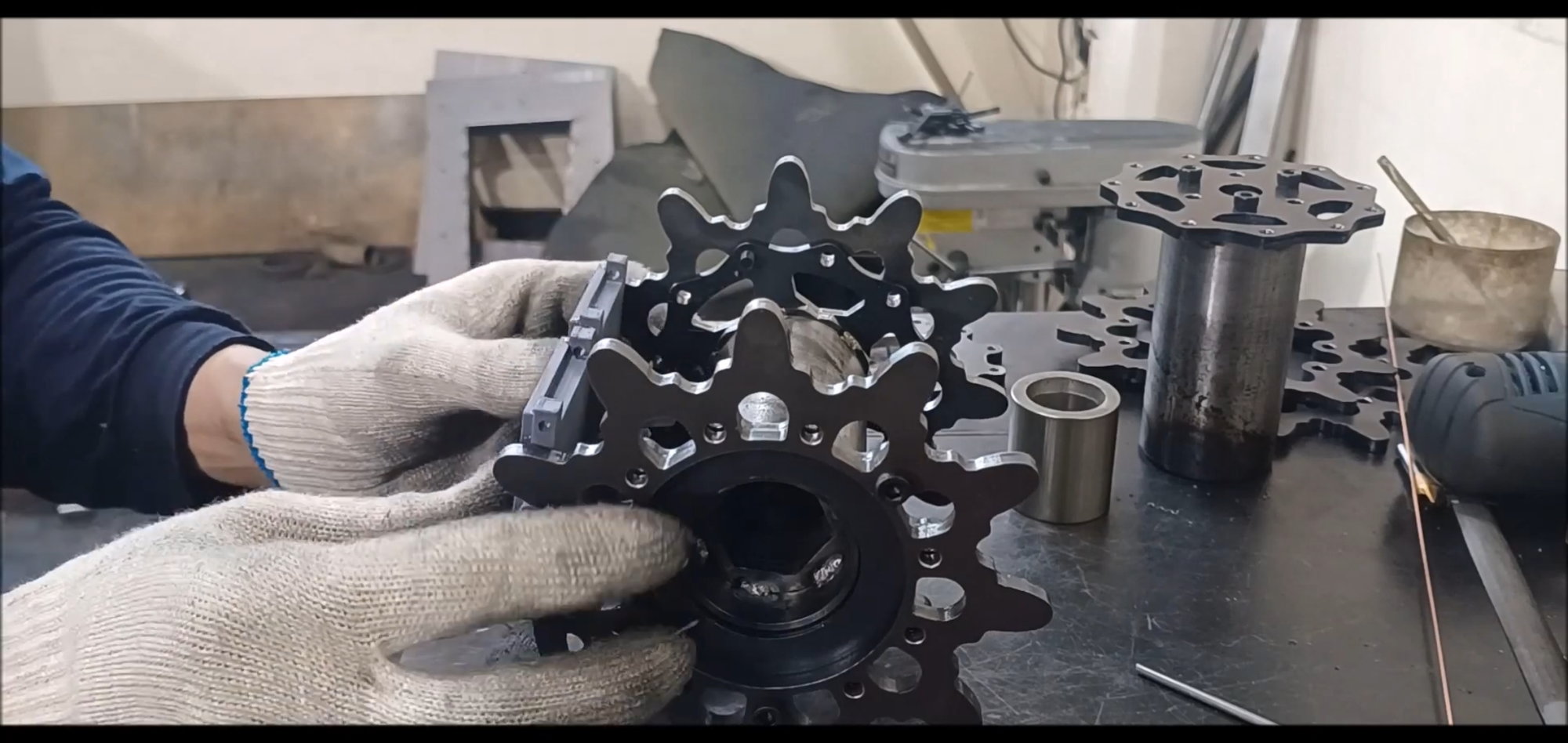

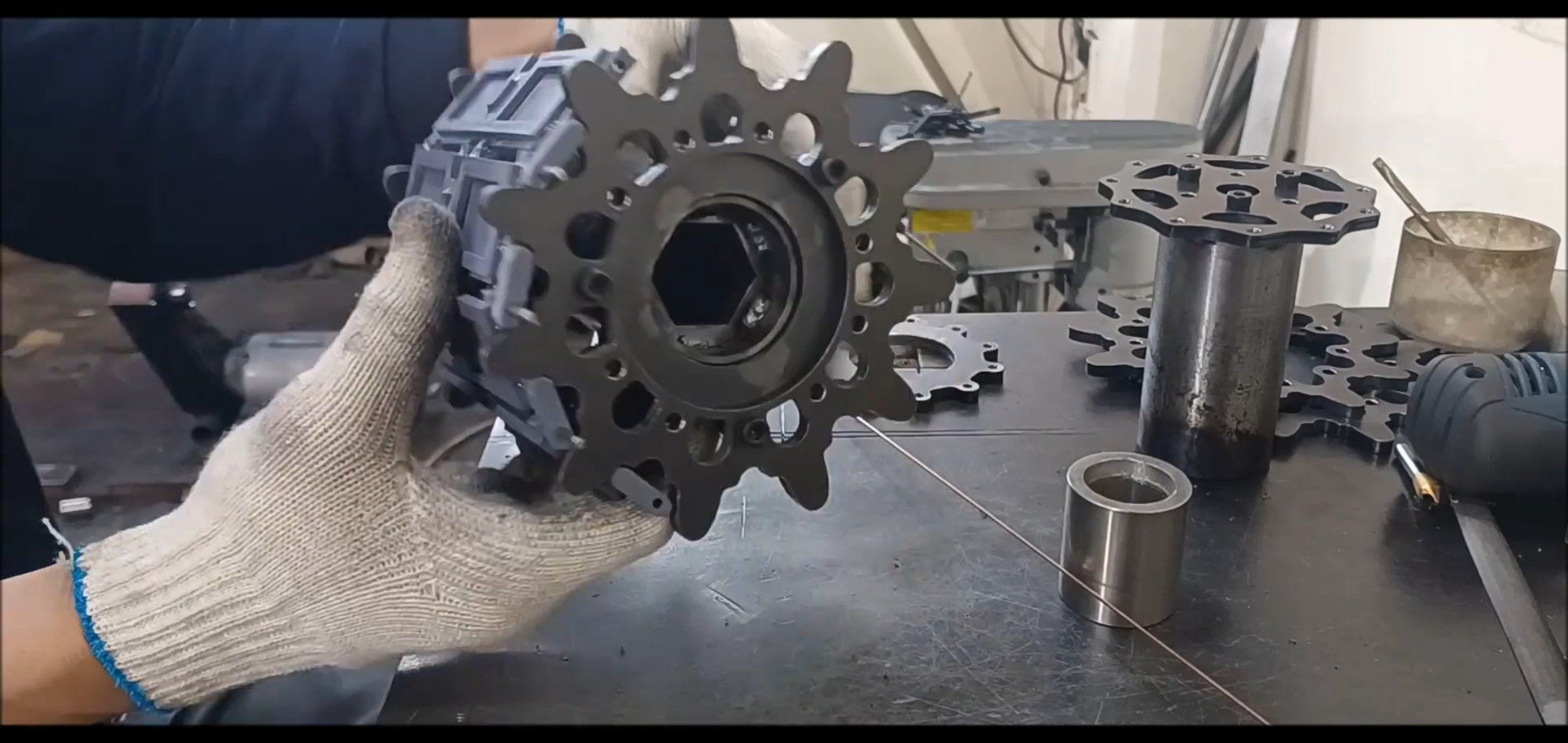

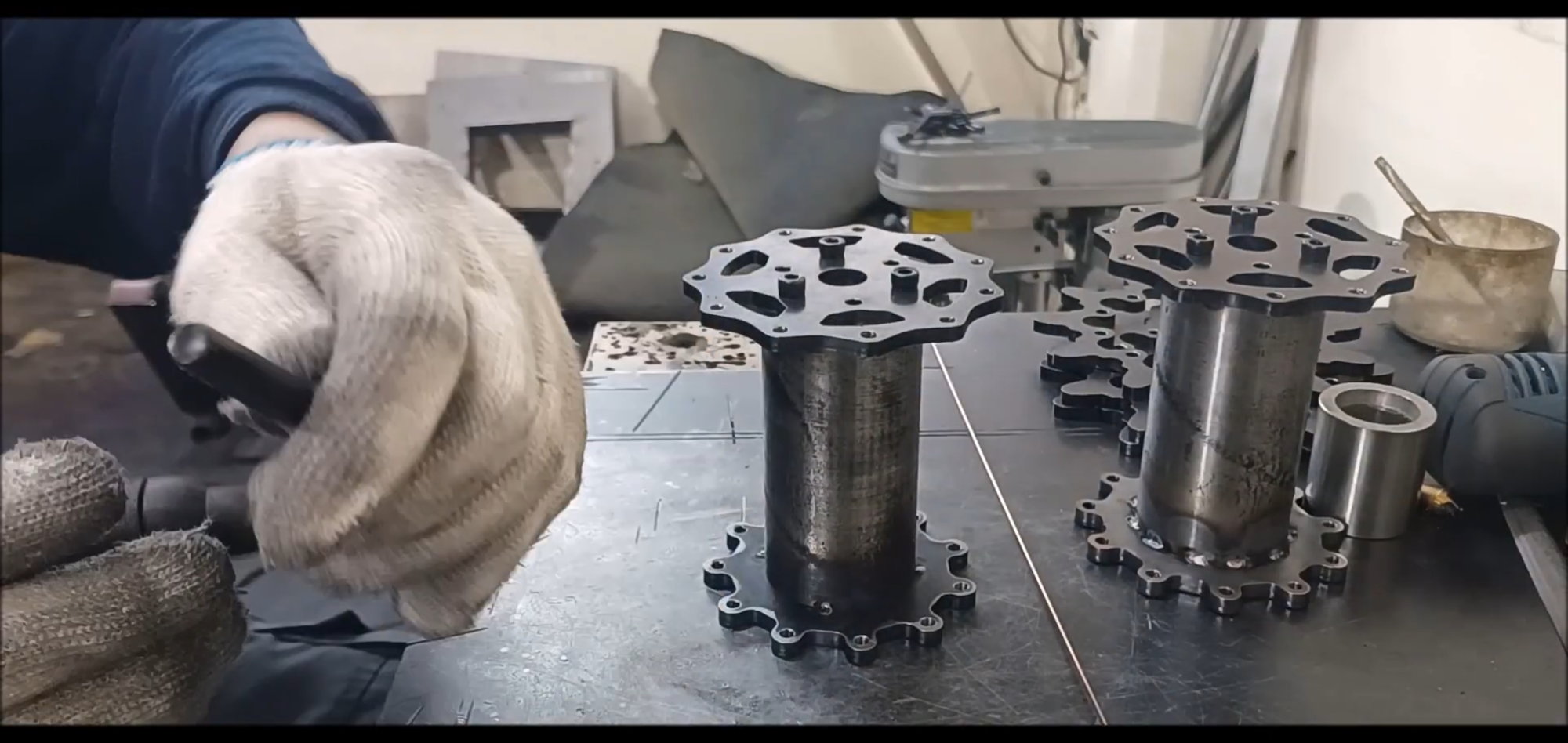

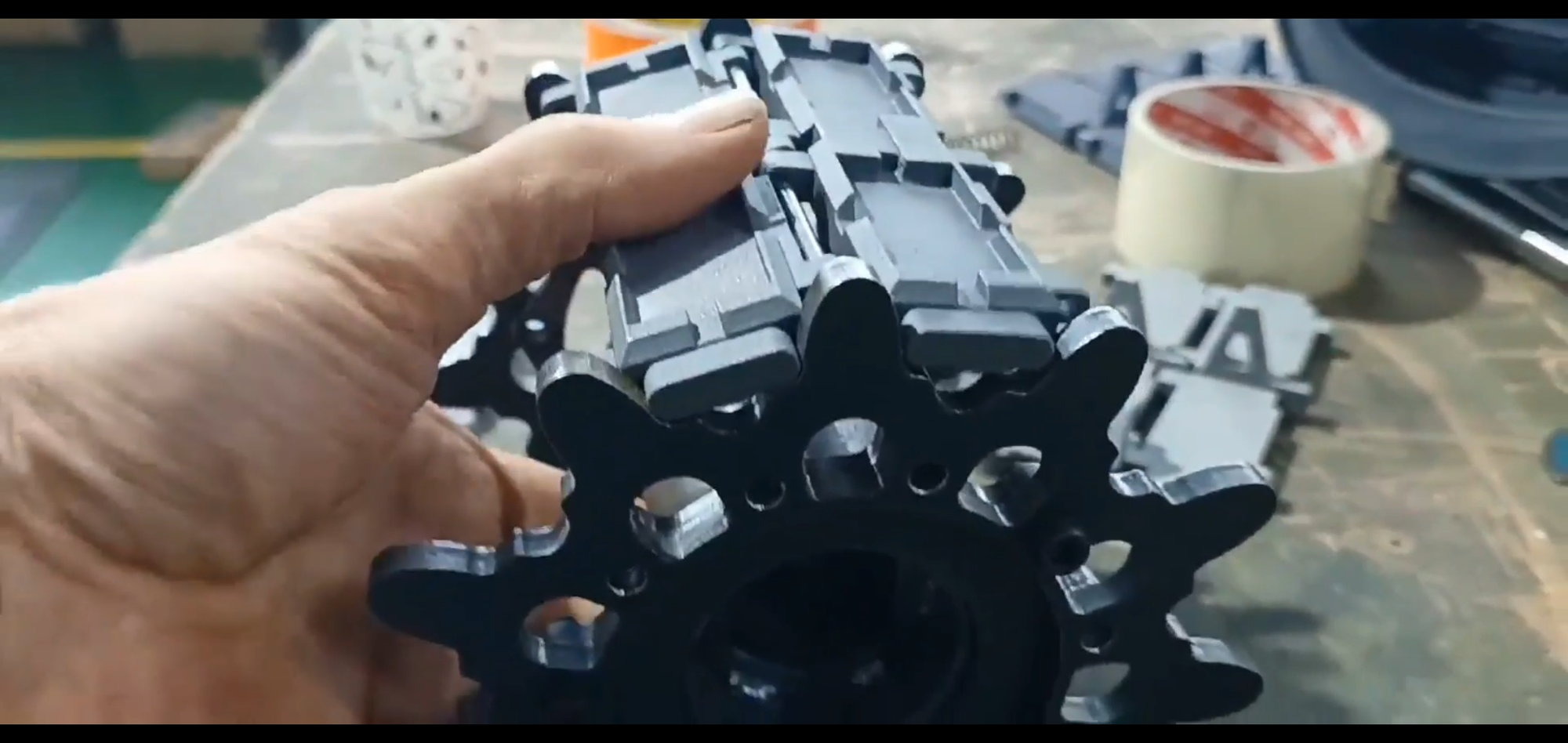

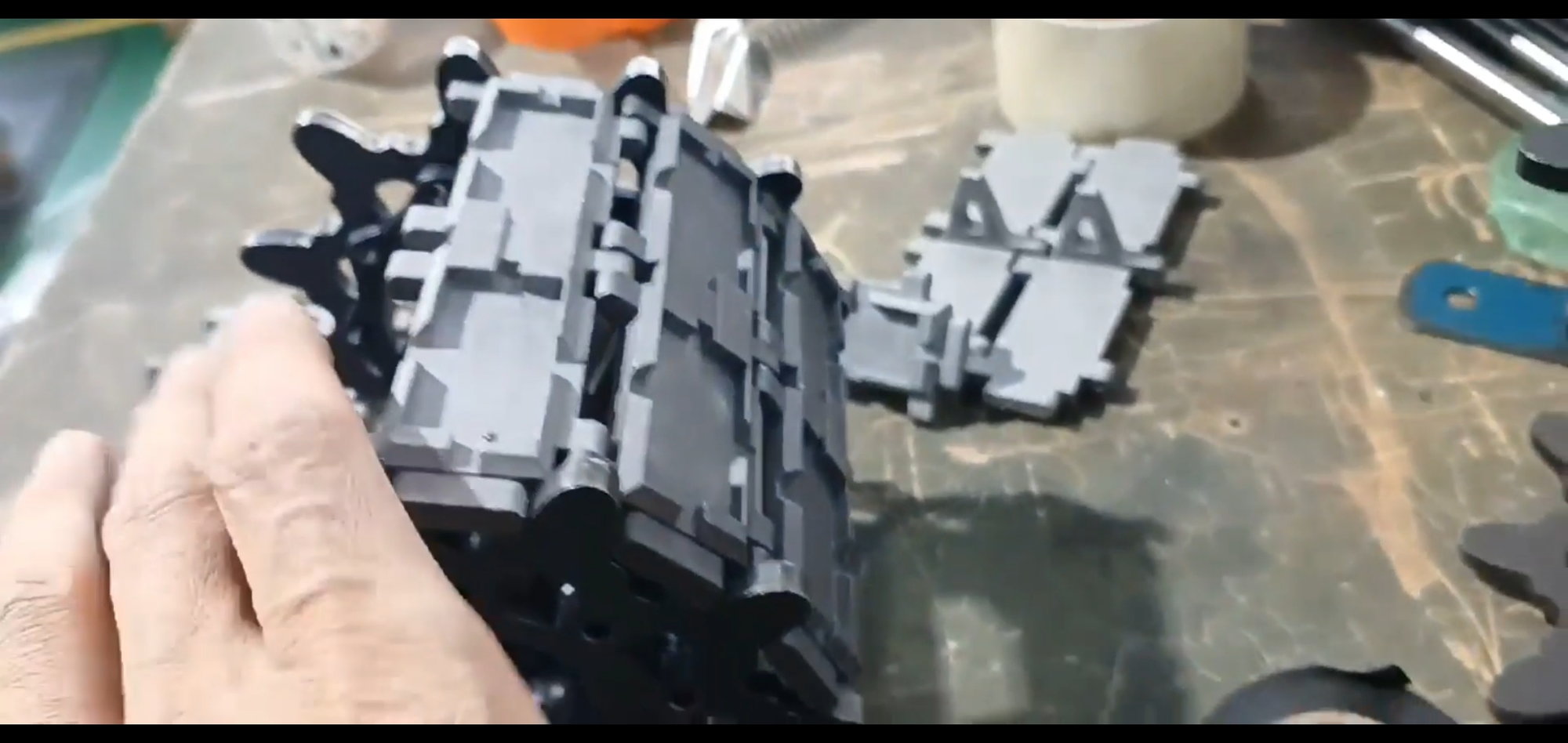

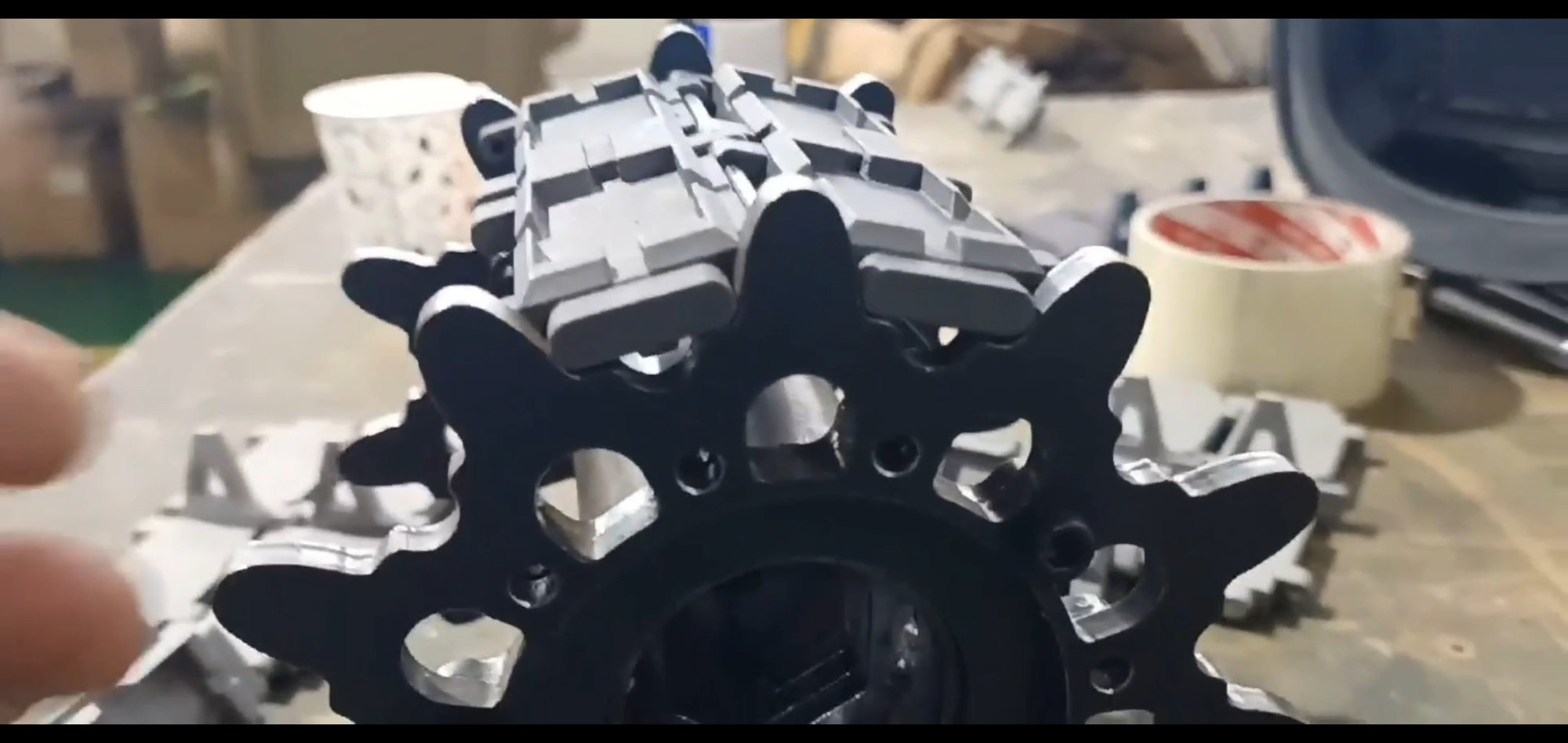

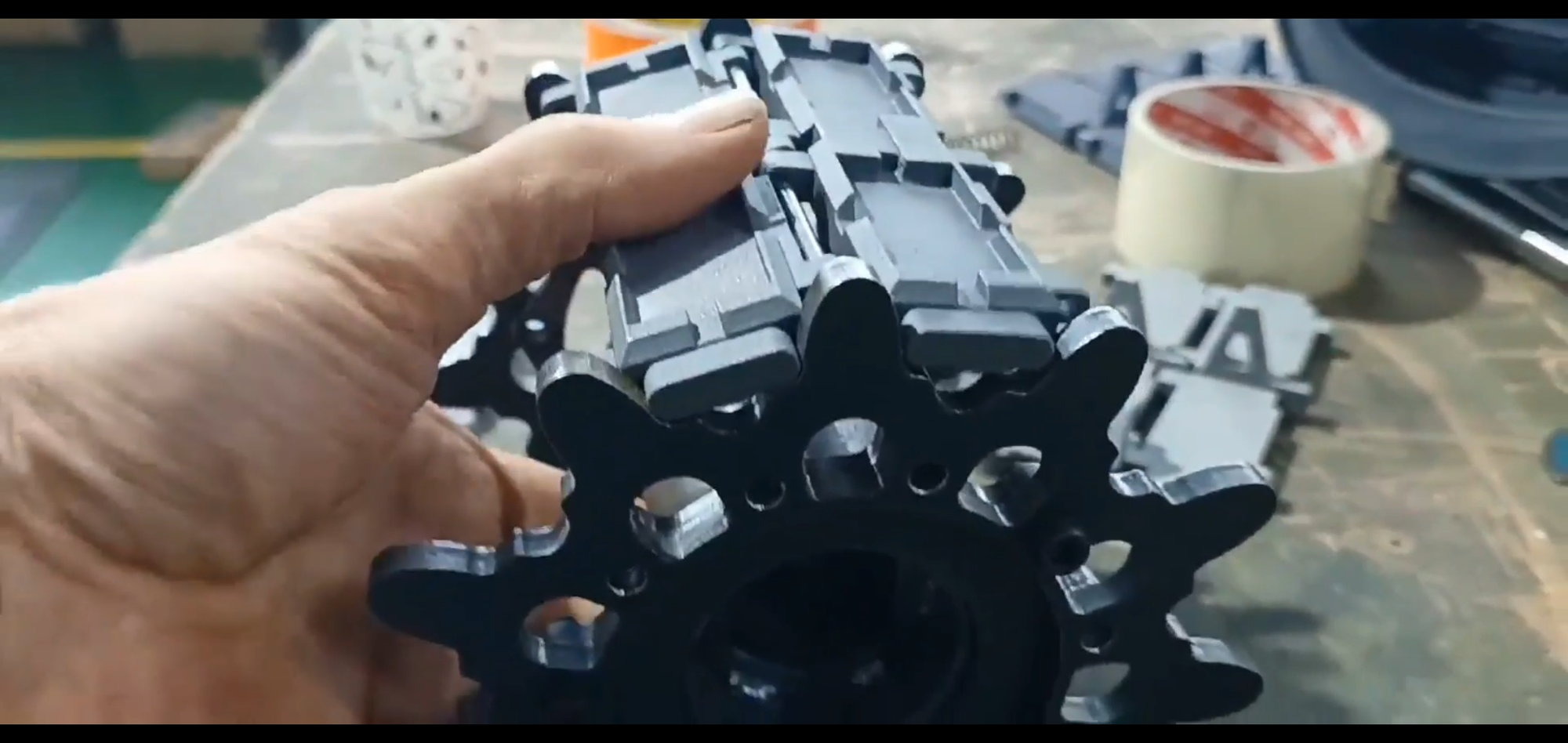

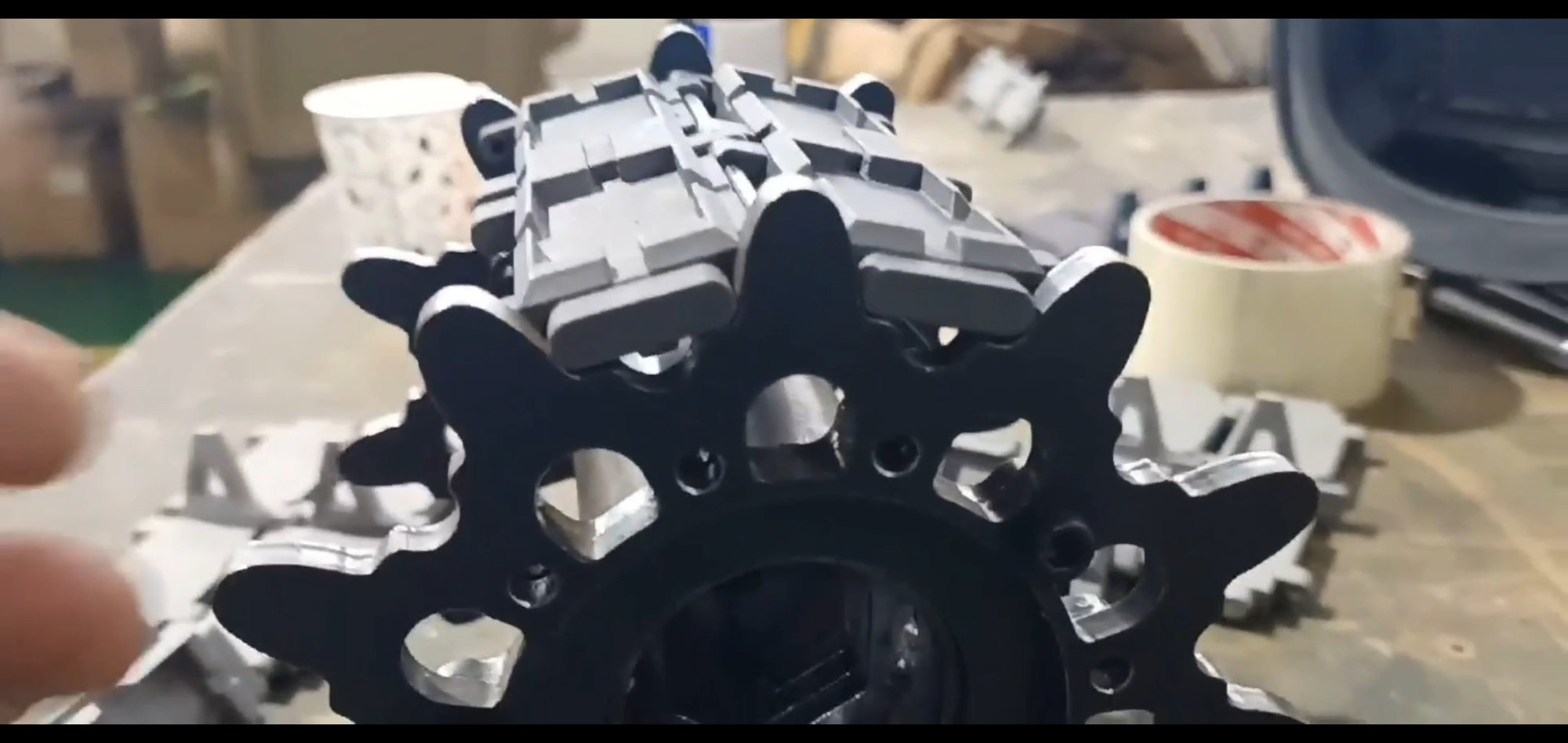

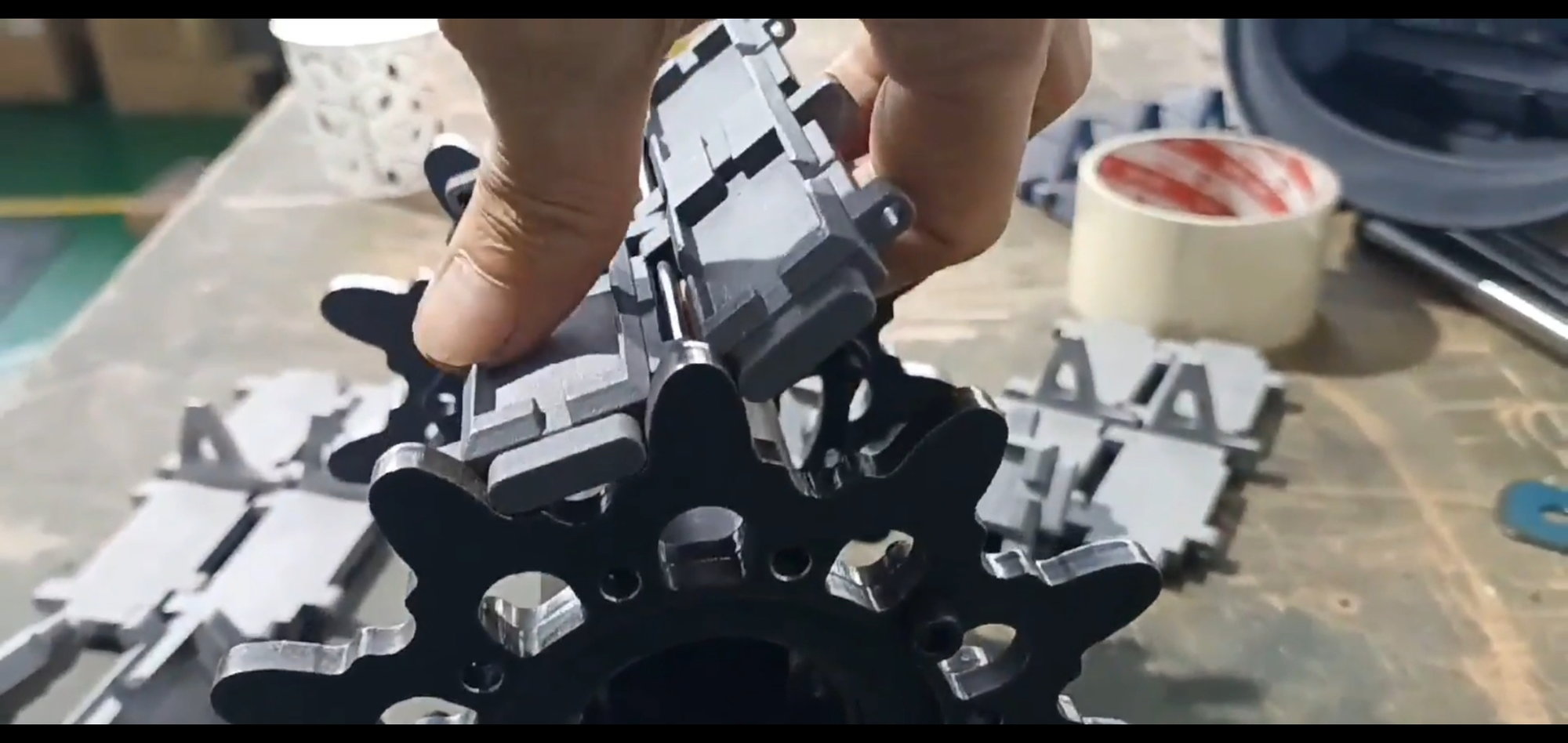

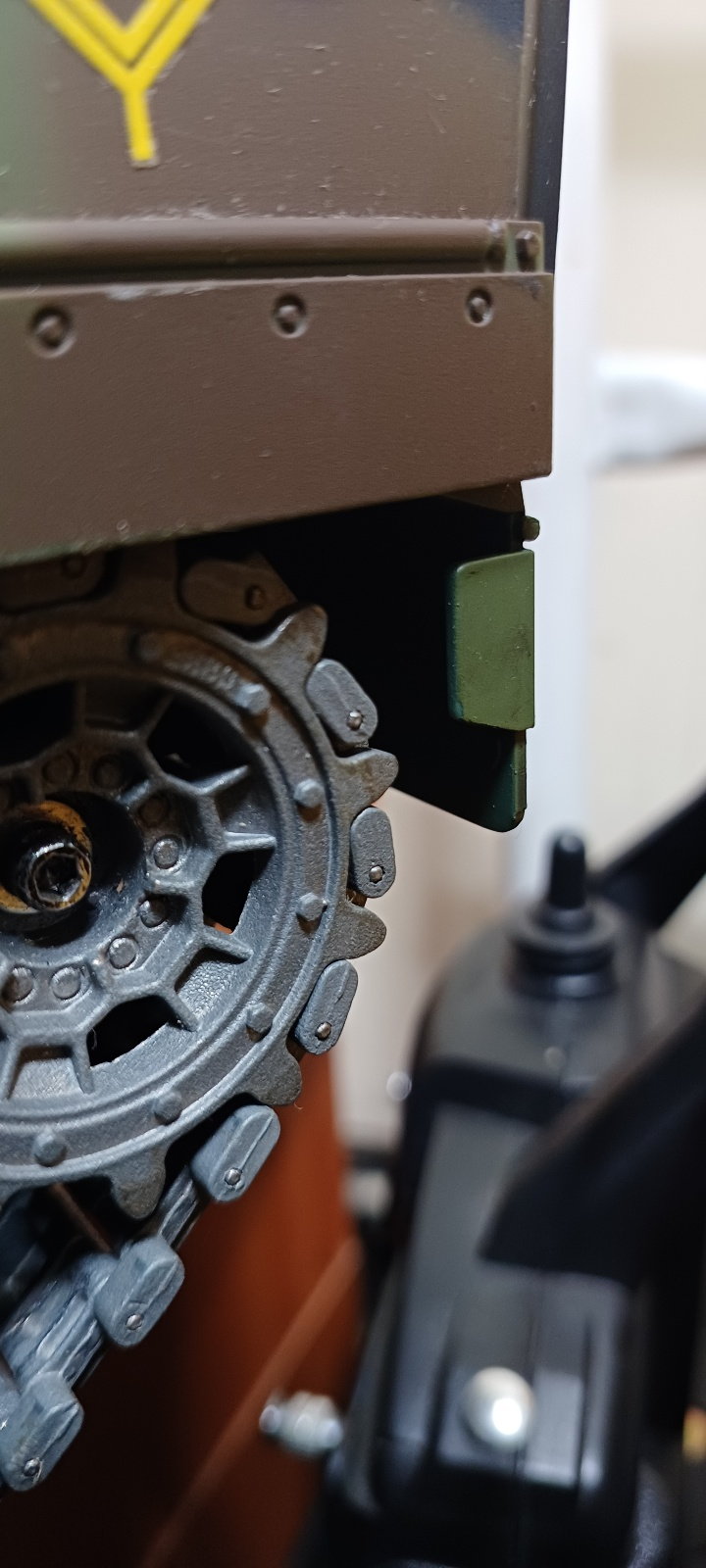

Following the last time, I will introduce the process of making the drive wheels.

The drive wheels are made of steel and will be polished toothed edges smoothly before installing the track.

Starting next week, the production process will be accelerated.

Regards.

Young

Once the cylindrical structure has been completed, welding will begin to secure the sawtooth gear wheels.

Fix with a temporary fixing wrench bolt.

Complex structures overlap. First, temporarily adjust the guide plate and seal reader insert plate.

Insert the above assembly into the cylinder.

Fine-tune the plane so that it is perpendicular to the cylinder.

Check Status

Welding preparation

Conduct fixed point welding

Remove the guide plate. Wrench bolts did not fall out due to thermal deformation when welding was performed without removal, as in the case of 2022 model

This place will be fixed with a hexagonal bolt later

It's a stressed area, so thorough welding is required

Finished welding fixed parts on top and bottom of cylinder

Welding of the outer fixing plate on the other side of the cylinder

Made in a lifelike shape for structural strength and three-dimensional effect of scale

Assemble the top and bottom sawtooth plates and shape them

Position the sawtooth with the 3D sculpture made in episode 1

Position the sawtooth with the 3D sculpture made in episode 1

Temporary fixation with point welds

Modify Location

full-scale welding

final inspection

final inspection

Re-decomposing and waiting

Re-decomposing and waiting

Check and disassemble the sprocket spacing

In the next episode......

The drive wheels are made of steel and will be polished toothed edges smoothly before installing the track.

Starting next week, the production process will be accelerated.

Regards.

Young

Once the cylindrical structure has been completed, welding will begin to secure the sawtooth gear wheels.

Fix with a temporary fixing wrench bolt.

Complex structures overlap. First, temporarily adjust the guide plate and seal reader insert plate.

Insert the above assembly into the cylinder.

Fine-tune the plane so that it is perpendicular to the cylinder.

Check Status

Welding preparation

Conduct fixed point welding

Remove the guide plate. Wrench bolts did not fall out due to thermal deformation when welding was performed without removal, as in the case of 2022 model

This place will be fixed with a hexagonal bolt later

It's a stressed area, so thorough welding is required

Finished welding fixed parts on top and bottom of cylinder

Welding of the outer fixing plate on the other side of the cylinder

Made in a lifelike shape for structural strength and three-dimensional effect of scale

Assemble the top and bottom sawtooth plates and shape them

Position the sawtooth with the 3D sculpture made in episode 1

Position the sawtooth with the 3D sculpture made in episode 1

Temporary fixation with point welds

Modify Location

full-scale welding

final inspection

final inspection

Re-decomposing and waiting

Re-decomposing and waiting

Check and disassemble the sprocket spacing

In the next episode......

The following 4 users liked this post by PE YOUNG:

#38

That process is a joy to watch. Thank you for documenting it.

The following users liked this post:

PE YOUNG (04-08-2023)

#39

If you compare the two drive sprockets, you'll notice the teeth on the model protruding WAY past the Links of the Tracks which I think might pose an issue for either the Track rolling on or off the Sprockets.

On a somewhat related note... Are they reusing parts of the Leopard 2 Family? That inner Hub of the Drive Sprocket looks kinda familiar 🤔🤨

On a somewhat related note... Are they reusing parts of the Leopard 2 Family? That inner Hub of the Drive Sprocket looks kinda familiar 🤔🤨

#40

Thread Starter

If you compare the two drive sprockets, you'll notice the teeth on the model protruding WAY past the Links of the Tracks which I think might pose an issue for either the Track rolling on or off the Sprockets.

On a somewhat related note... Are they reusing parts of the Leopard 2 Family? That inner Hub of the Drive Sprocket looks kinda familiar 🤔🤨

On a somewhat related note... Are they reusing parts of the Leopard 2 Family? That inner Hub of the Drive Sprocket looks kinda familiar 🤔🤨

Most Western-made tanks weigh over 60 TON and produce tracks using the German Leopard's trackmaking technology.

In the 1970s, when the U.S. developed a MBT in collaboration with Germany, it conceived a track called the T-158.

The tracks of recent NATO standard Western armoured equipment are similar.

Armoured tracks in Korea will be replaced with rubber tracks in the future.

South Korea has decided to independently localize its rubber orbit under the auspices of the Institute of Defense Development, as it has now used products made by Canada's Soucy Defense for its Redback infantry armoured vehicles.

Please refer to the link below for Korea's track production.

https://www.lstrackshoe.co.kr:8003/products/

In this model fabrication, the track will be somewhat simplified, considering the convenience and durability of fabrication rather than scale precision. (See previous news)

Regards,

Young

Last edited by PE YOUNG; 04-08-2023 at 06:09 PM.

The following users liked this post:

tankme (04-08-2023)

#42

Thread Starter

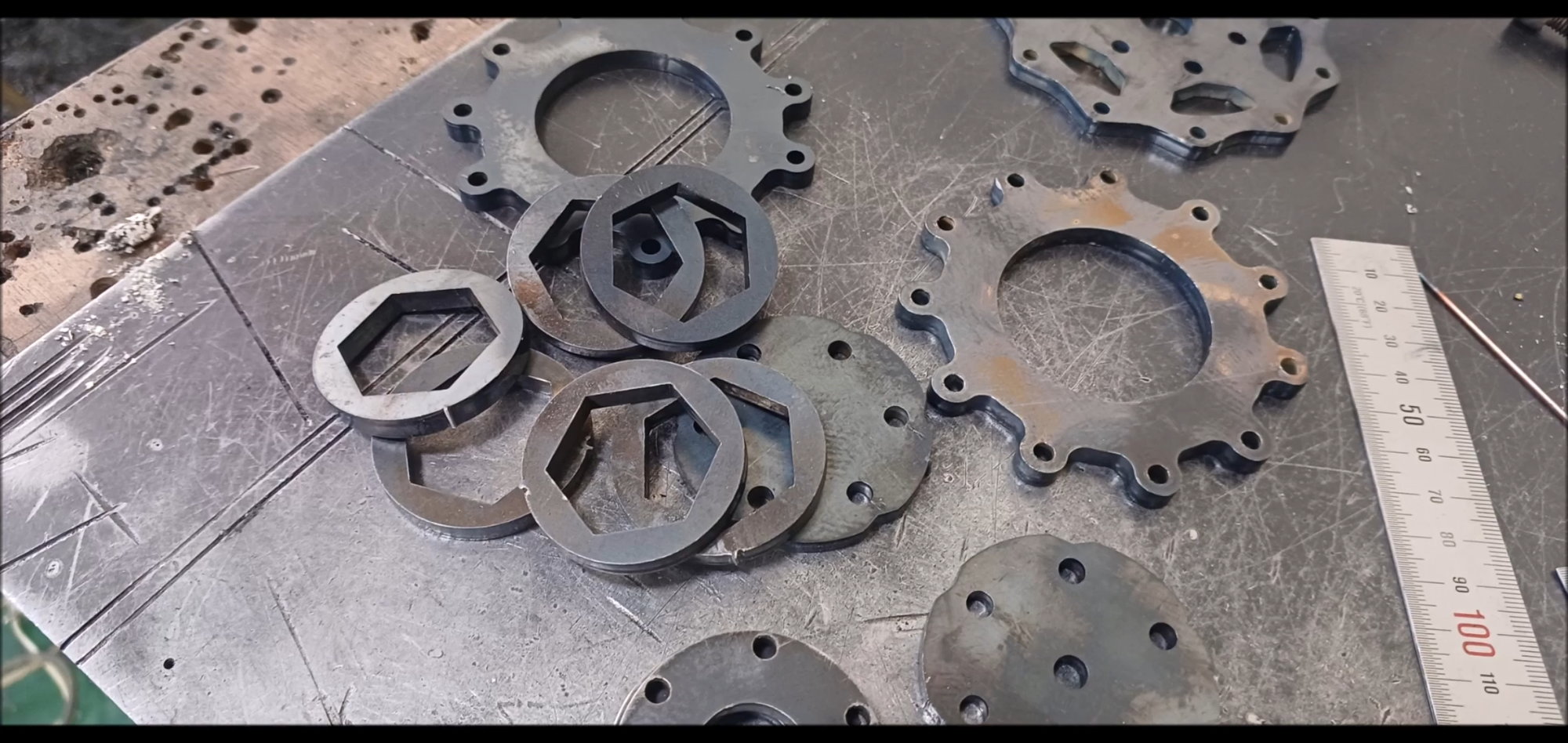

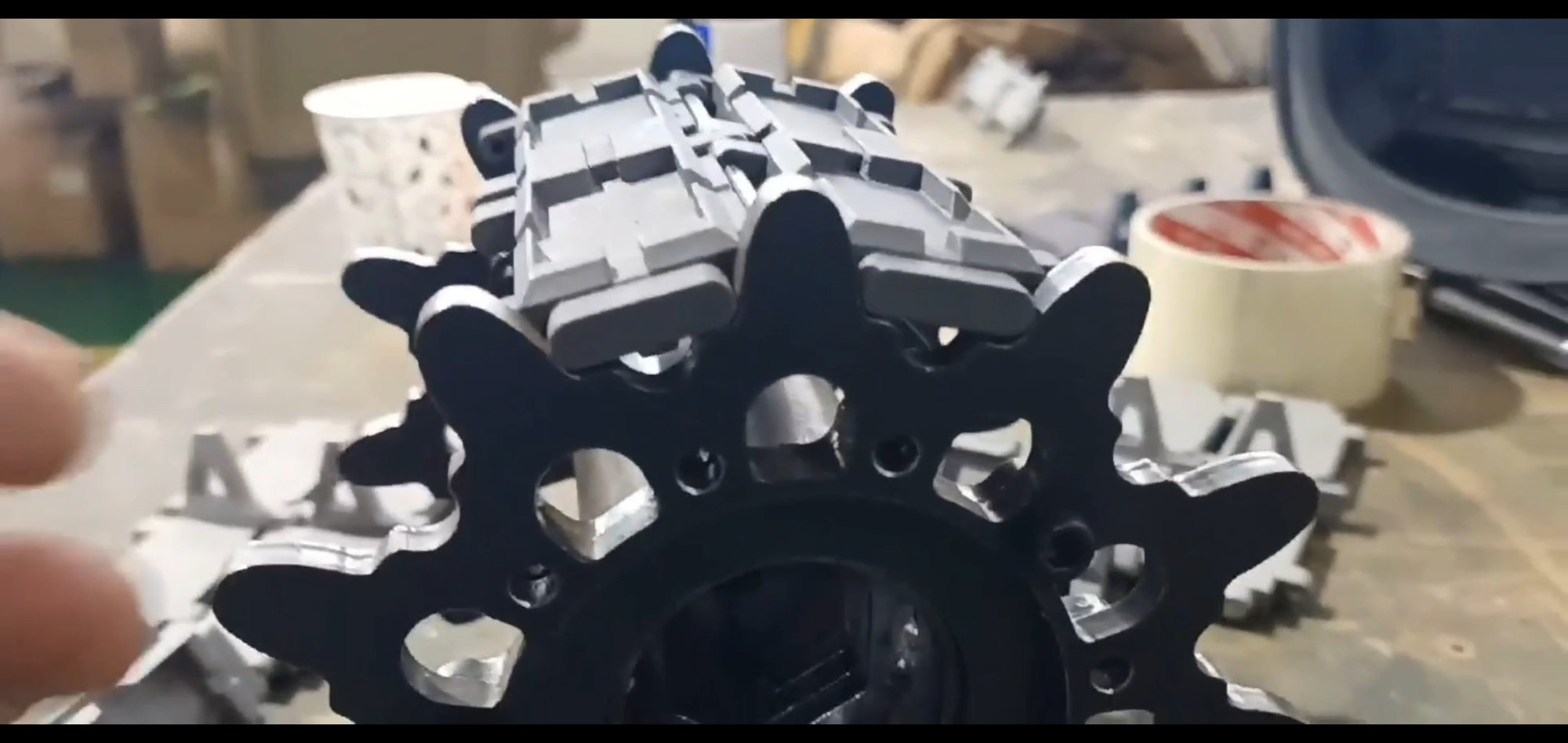

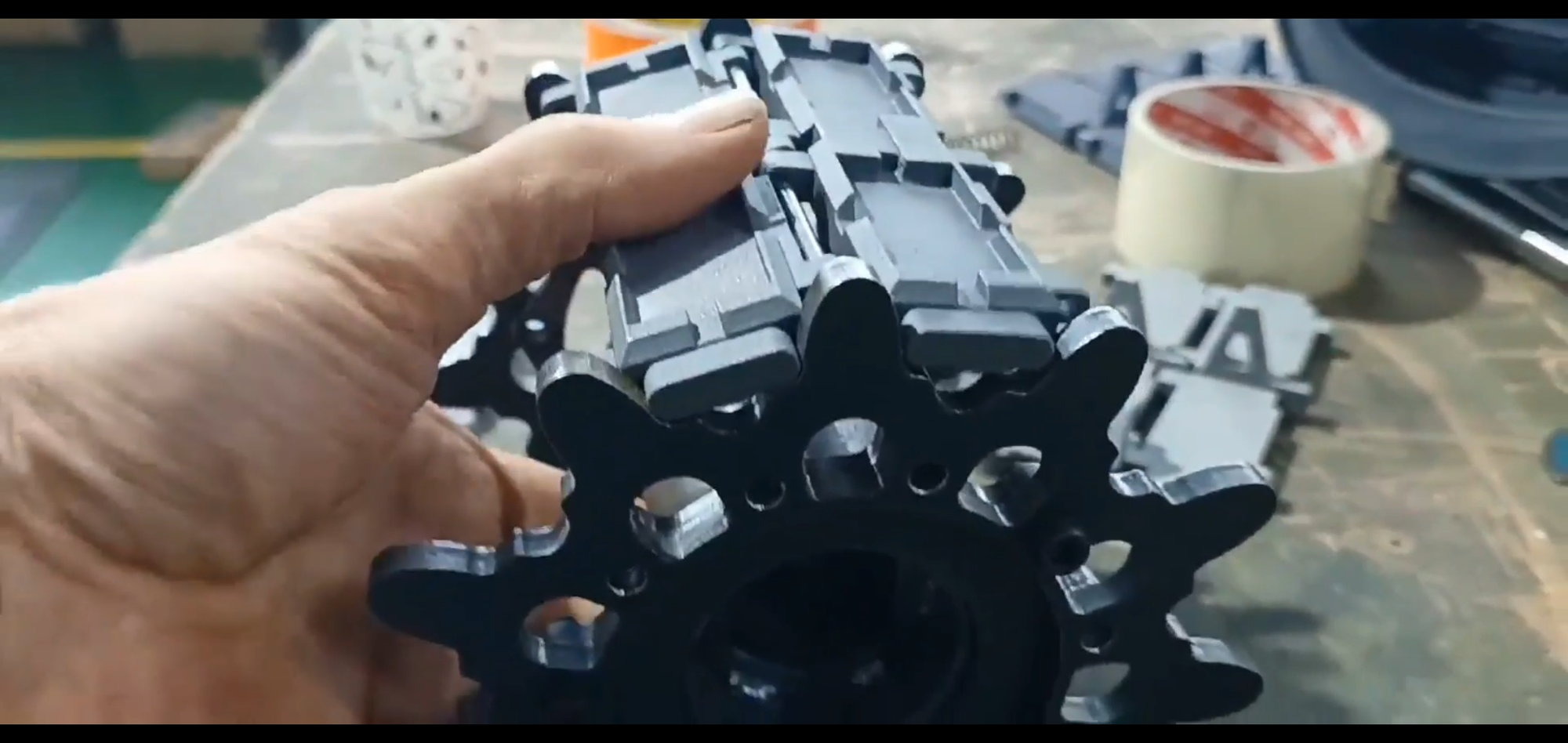

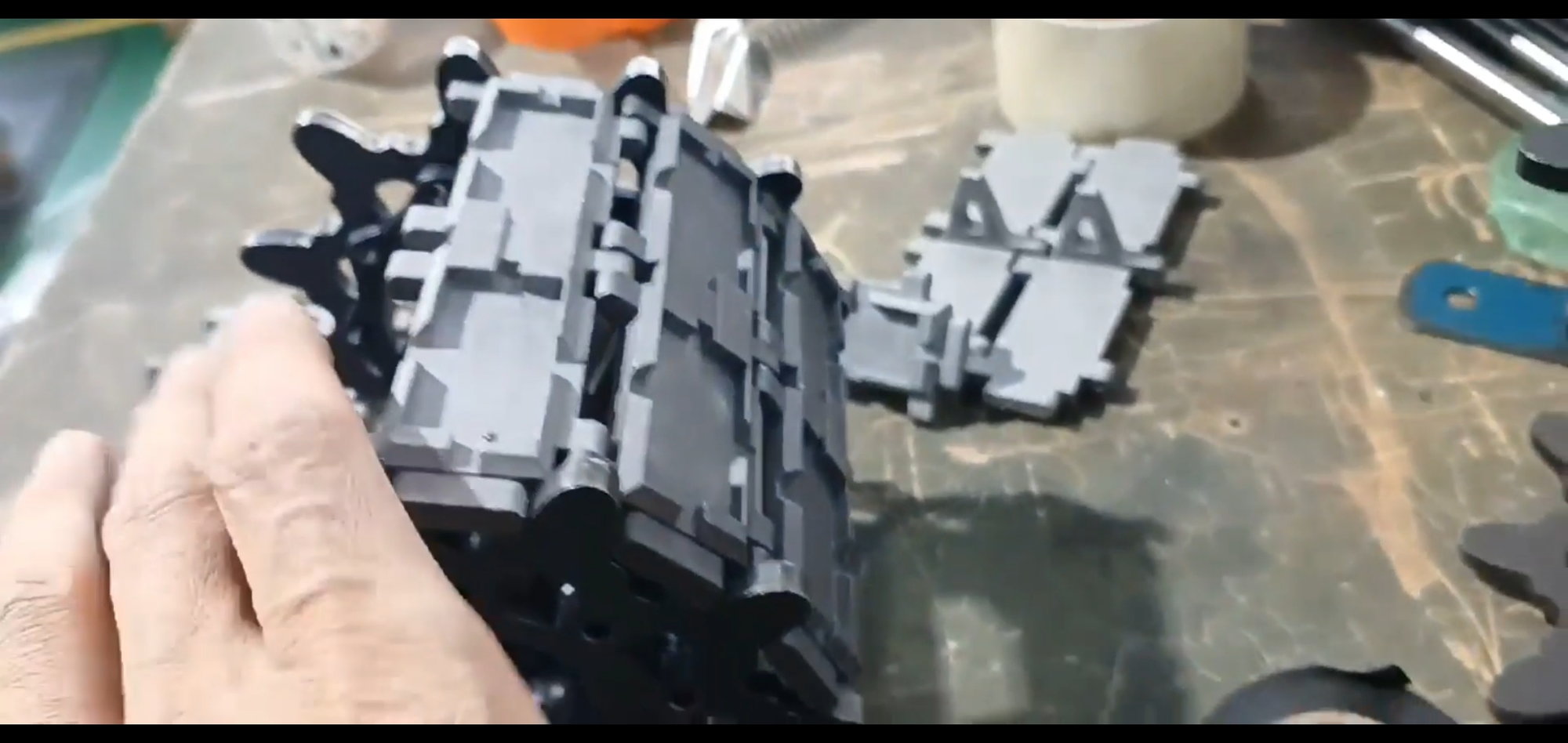

The tank manufacturer decided to manufacture and install the caterpillar of the 2023 1/5 scale Black Panther tank (project name: ic2504) by casting method. The optimal method is to increase production efficiency and reduce the number of iterations.

The shape of the track is somewhat different from the actual one, but it is strong and has increased assembly efficiency.

The production is outsourced processing, and the outsourced production has been requested today.

Regards,

Young

Upper shape of caterpillar

the lower appearance of the caterpillar

The shape of the track is somewhat different from the actual one, but it is strong and has increased assembly efficiency.

The production is outsourced processing, and the outsourced production has been requested today.

Regards,

Young

Upper shape of caterpillar

the lower appearance of the caterpillar

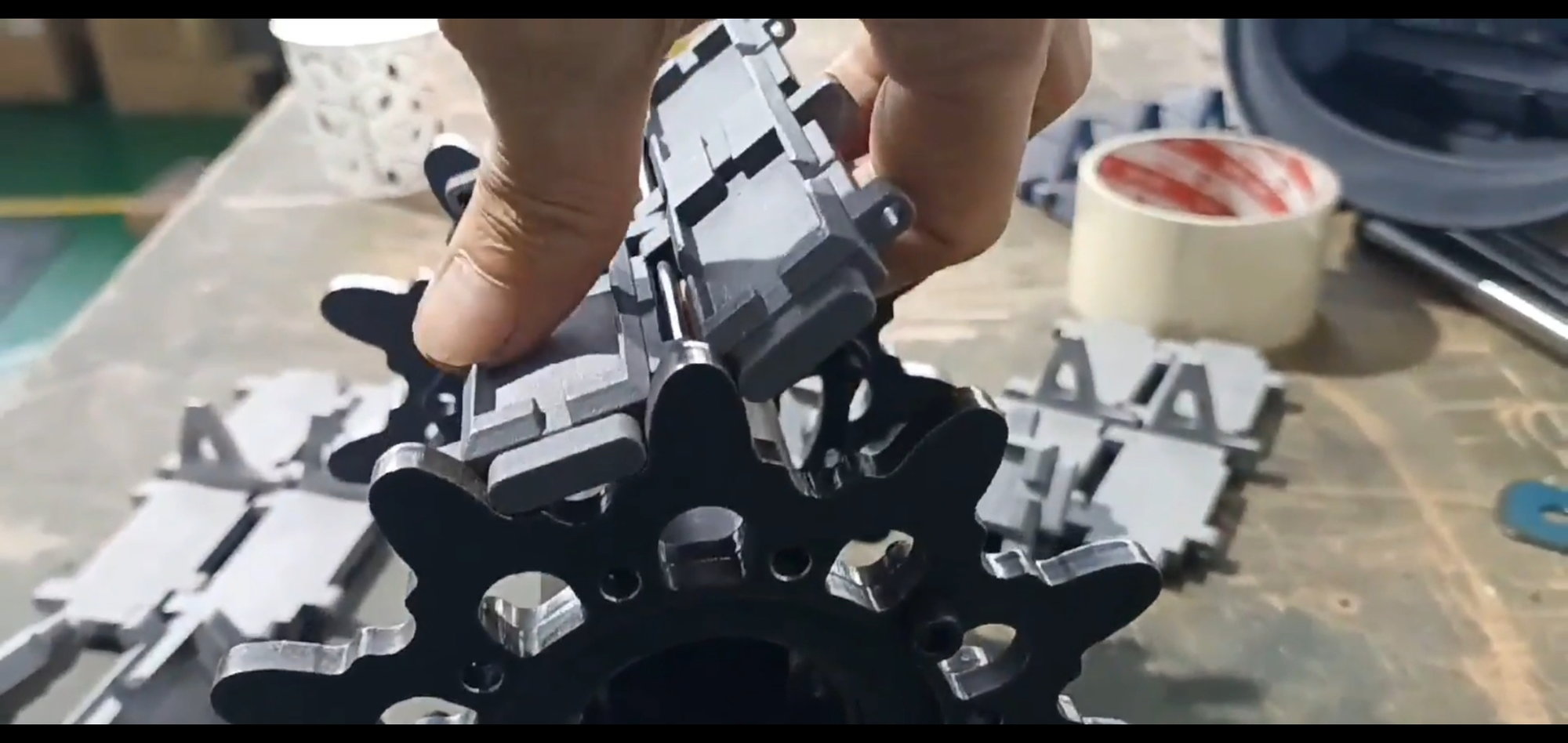

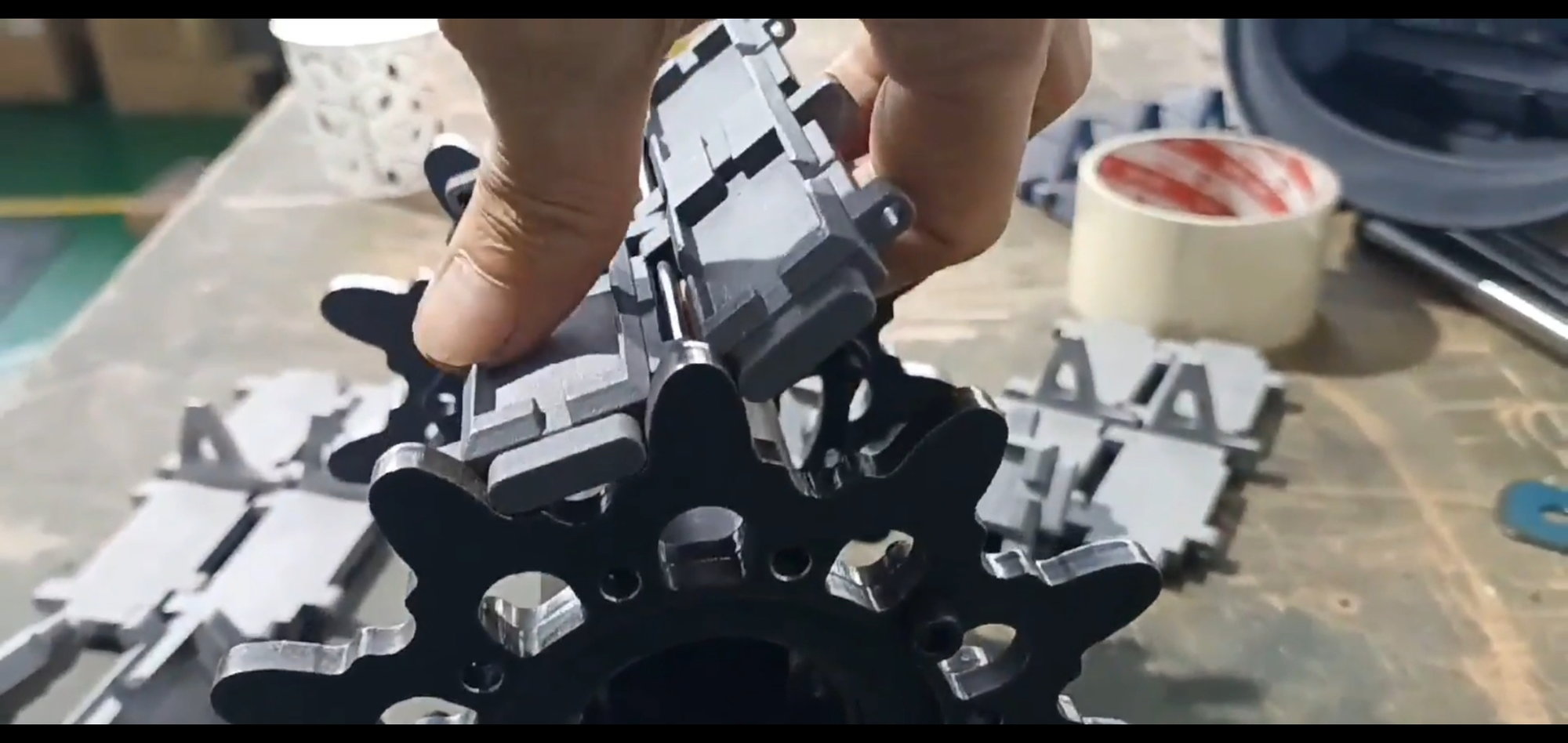

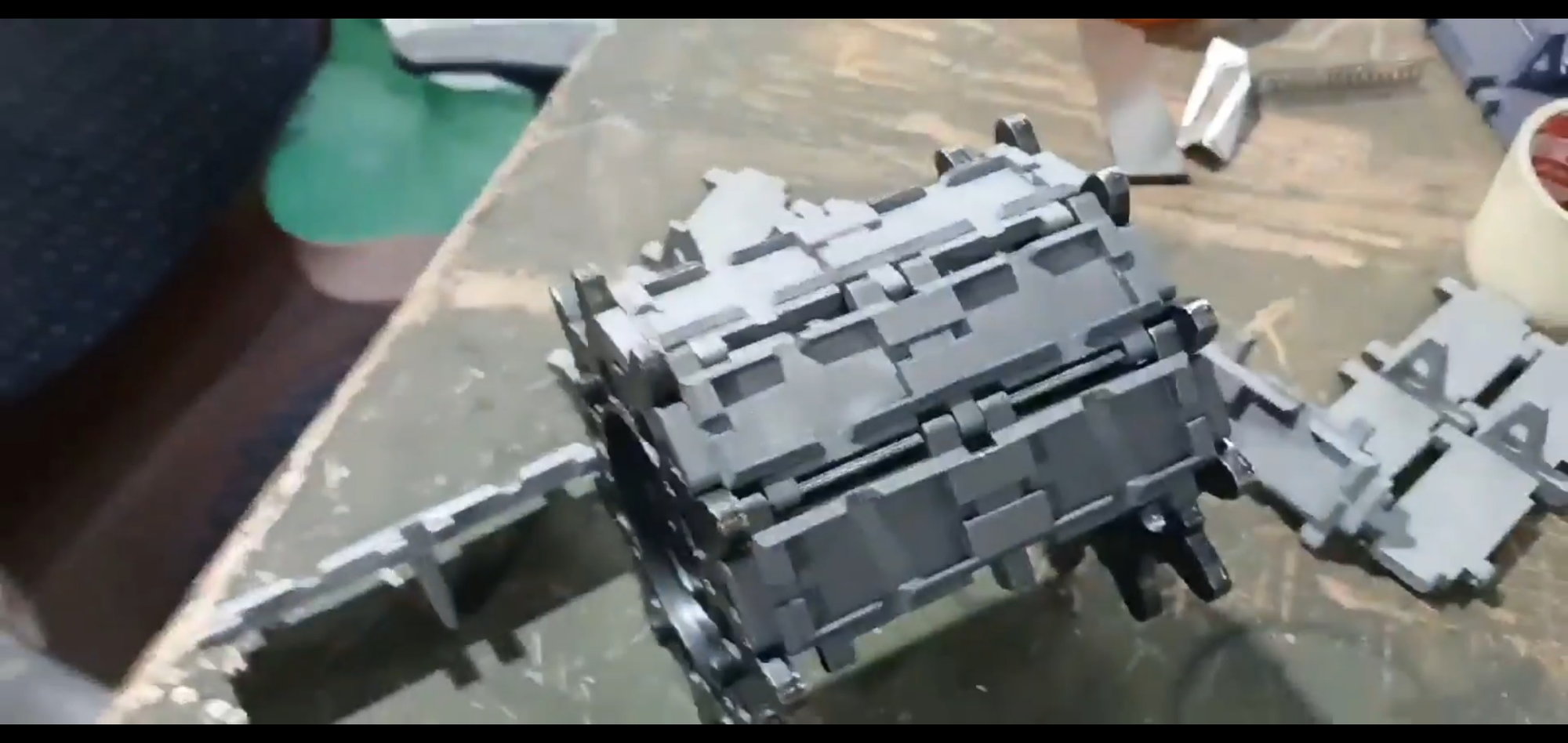

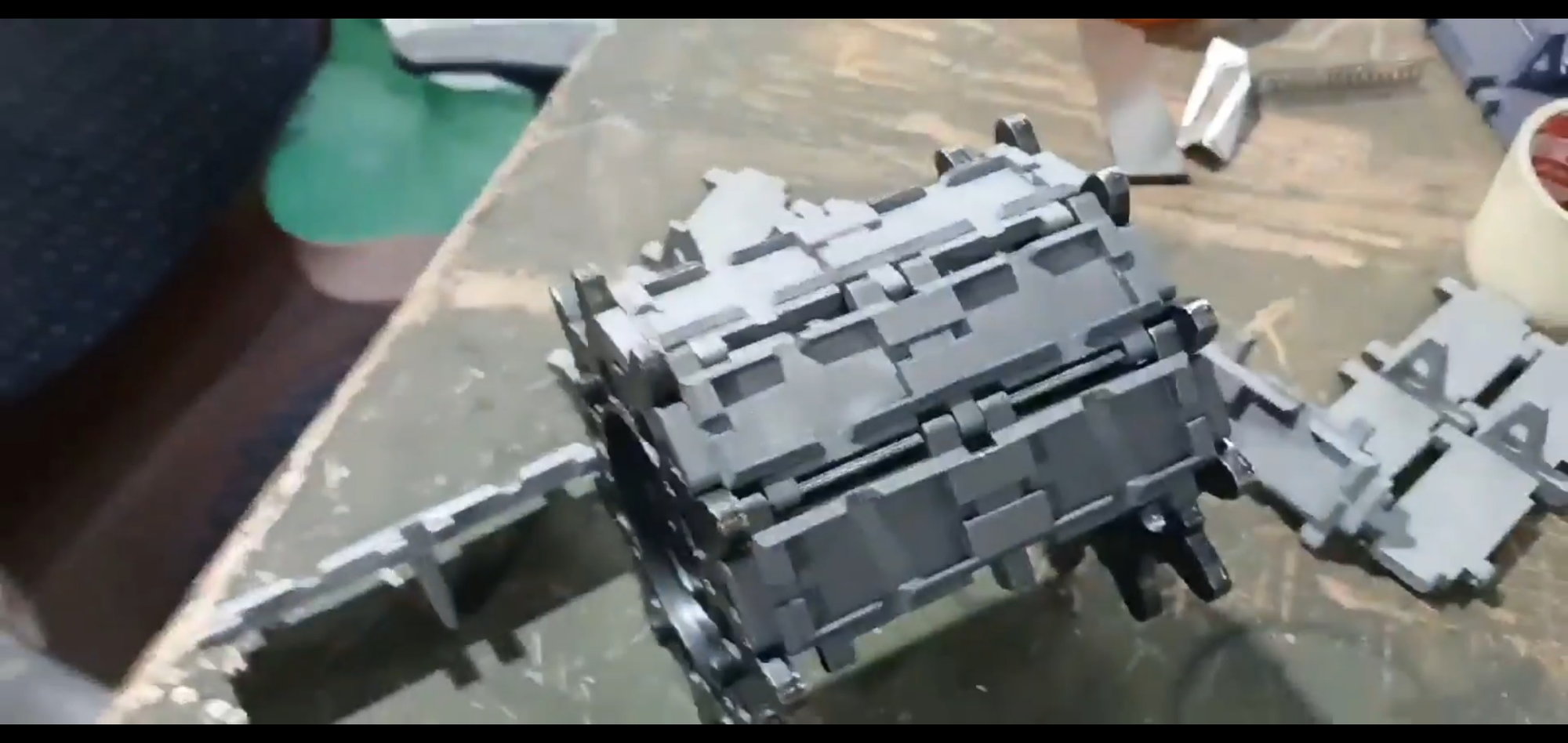

The sample of the casting track by outsourcing arrived the other day.

The connection is more natural and powerful

Check by hanging it on the sprocket that was made last time

Tightly operated to show less track deviations

The material is bolt steel

It's harder than normal casting

Its surface is grayed out by working with Sendblaster

Make holes and tap screws manually.

#43

Thread Starter

A few days ago, a sample of a track made by outsourcing arrived and will be inspected

The sample of the casting track by outsourcing arrived the other day.

The connection is more natural and powerful

Check by hanging it on the sprocket that was made last time

Tightly operated to show less track deviations

The material is bolt steel

It's harder than normal casting

Its surface is grayed out by working with Sendblaster

Make holes and tap screws manually.

The sample of the casting track by outsourcing arrived the other day.

The connection is more natural and powerful

Check by hanging it on the sprocket that was made last time

Tightly operated to show less track deviations

The material is bolt steel

It's harder than normal casting

Its surface is grayed out by working with Sendblaster

Make holes and tap screws manually.

It's a 2022 k2 and it's a miniature version of the real track.

Looking at the case where the smaller-scale leopard tank has one hinge point, the wave shape appears

As a result of reviewing the driving behavior with a 3D printer sample, the shape of the waves was severe, so the casting method was changed

#44

Thread Starter

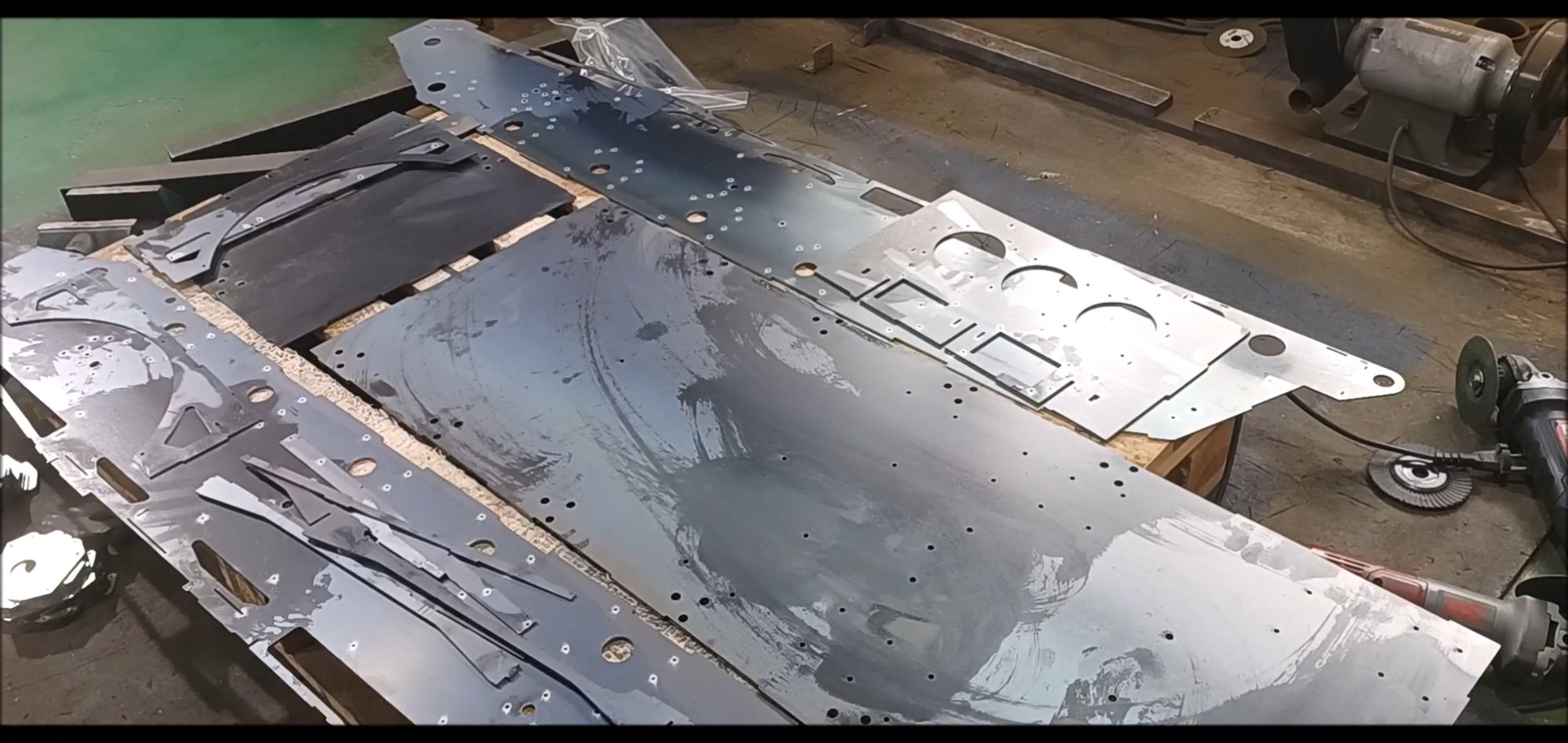

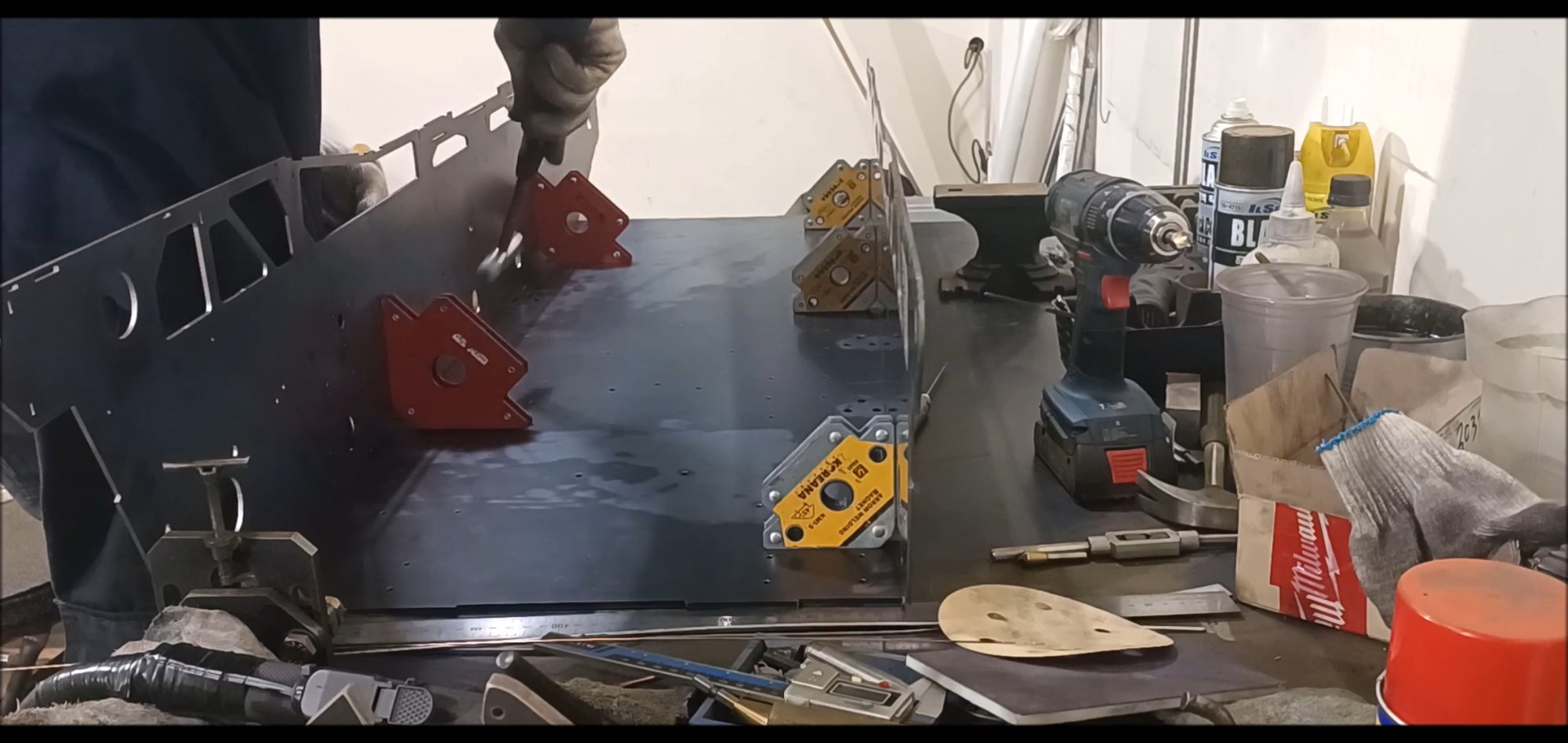

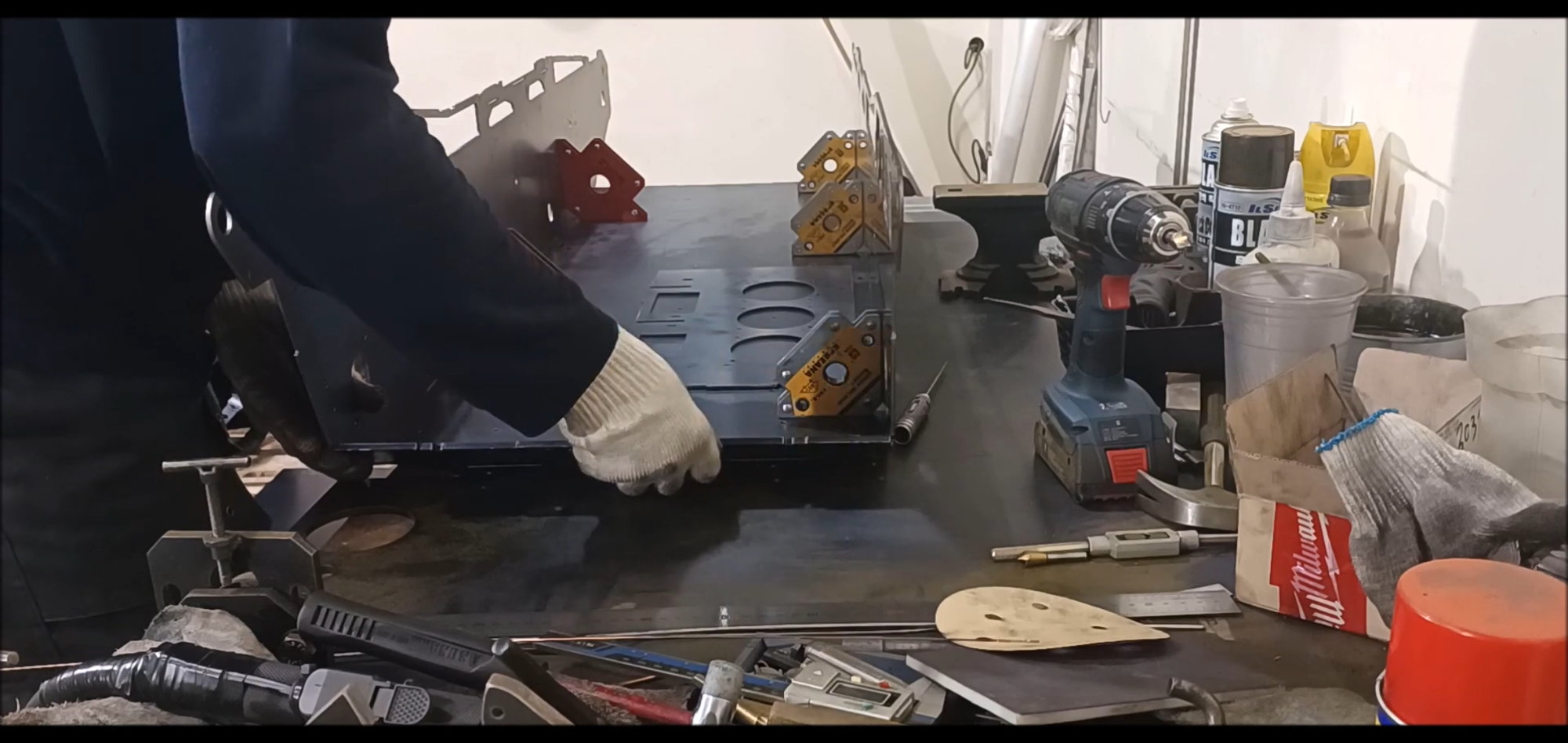

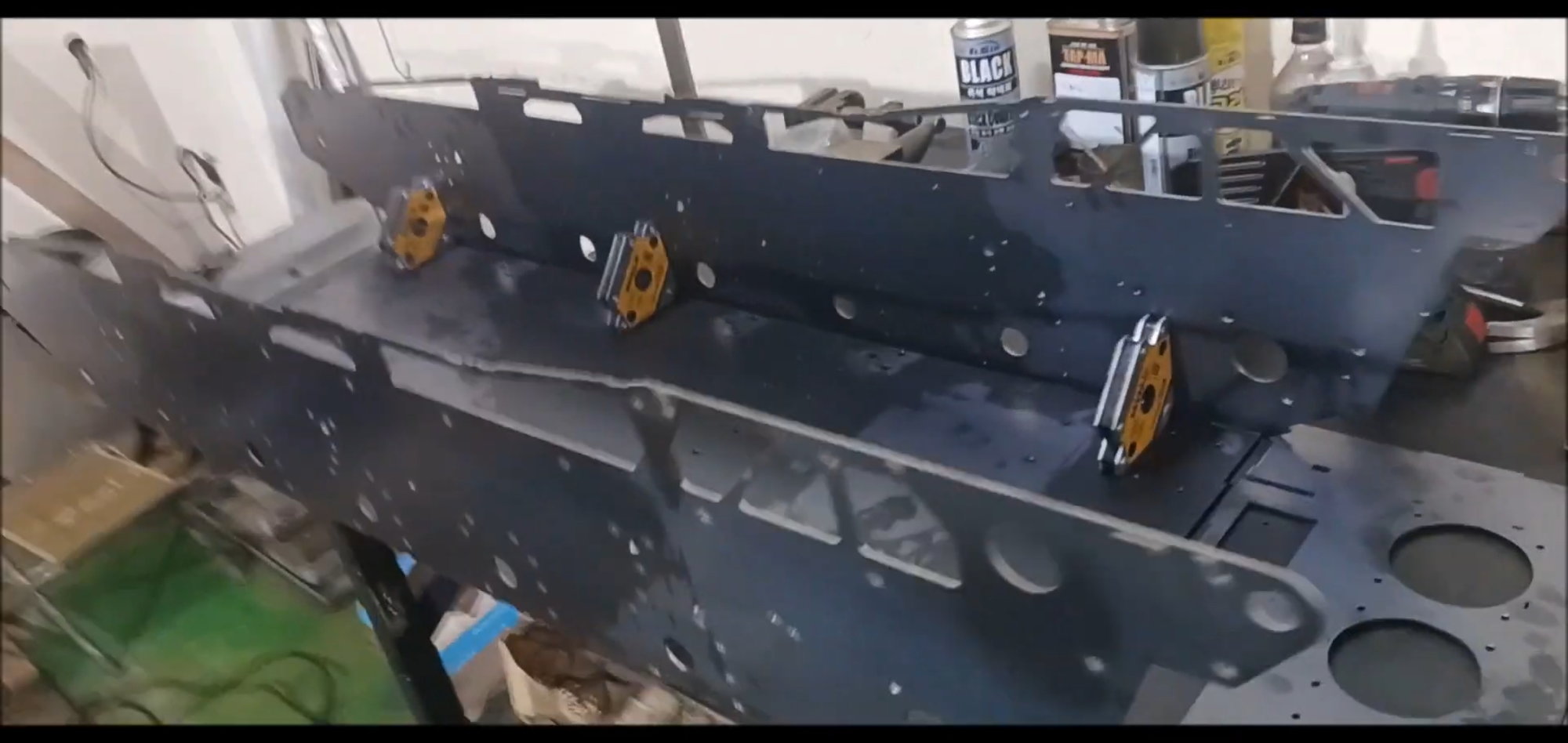

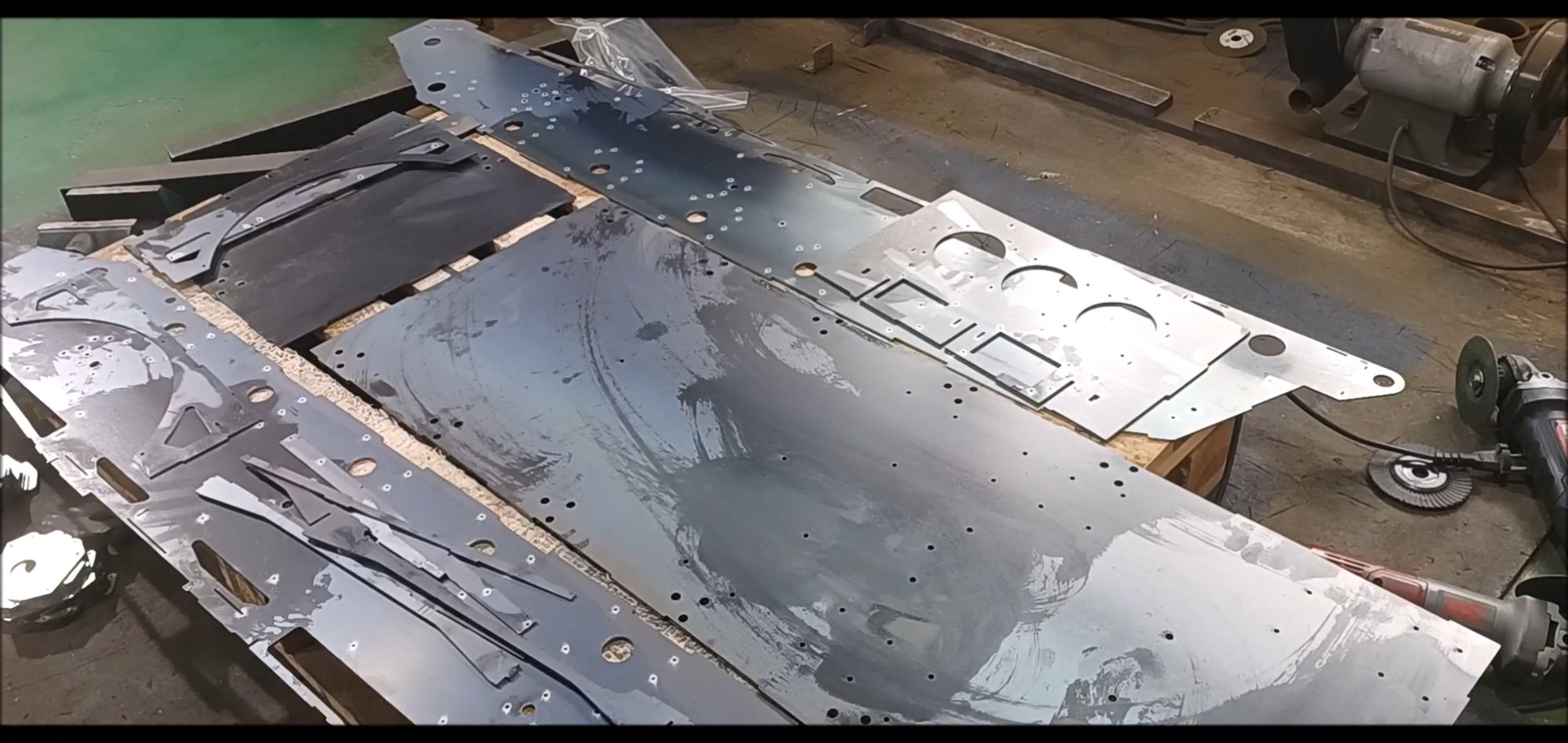

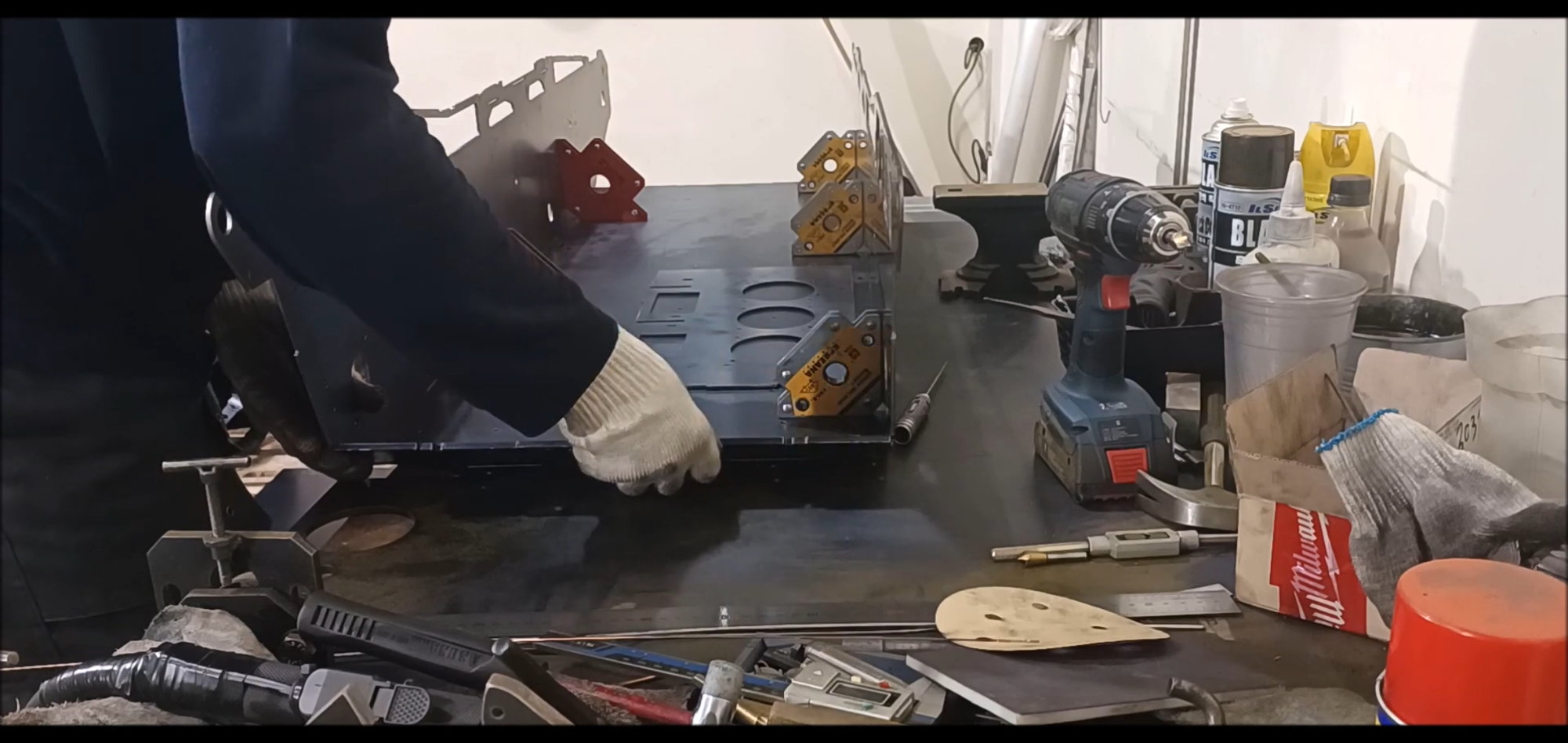

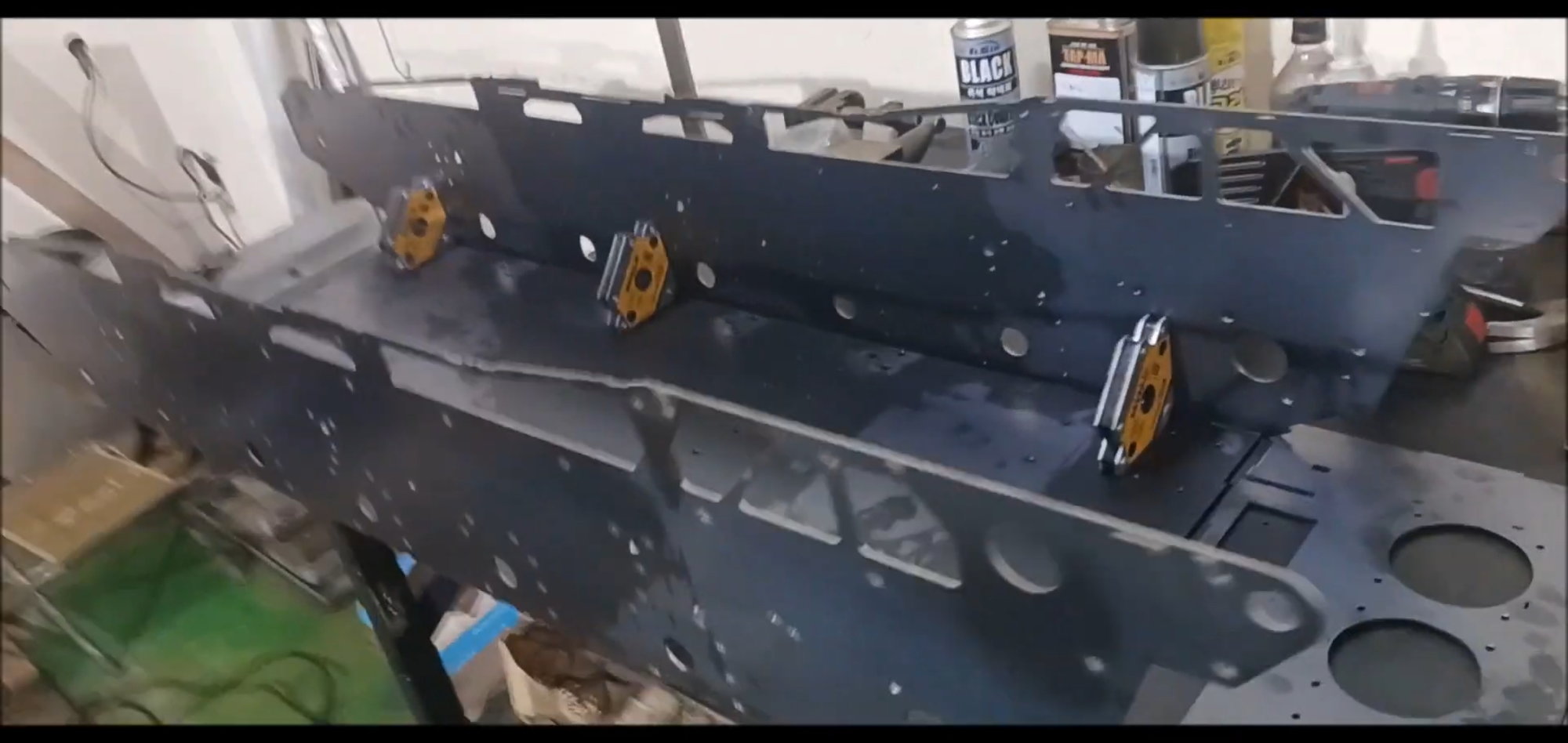

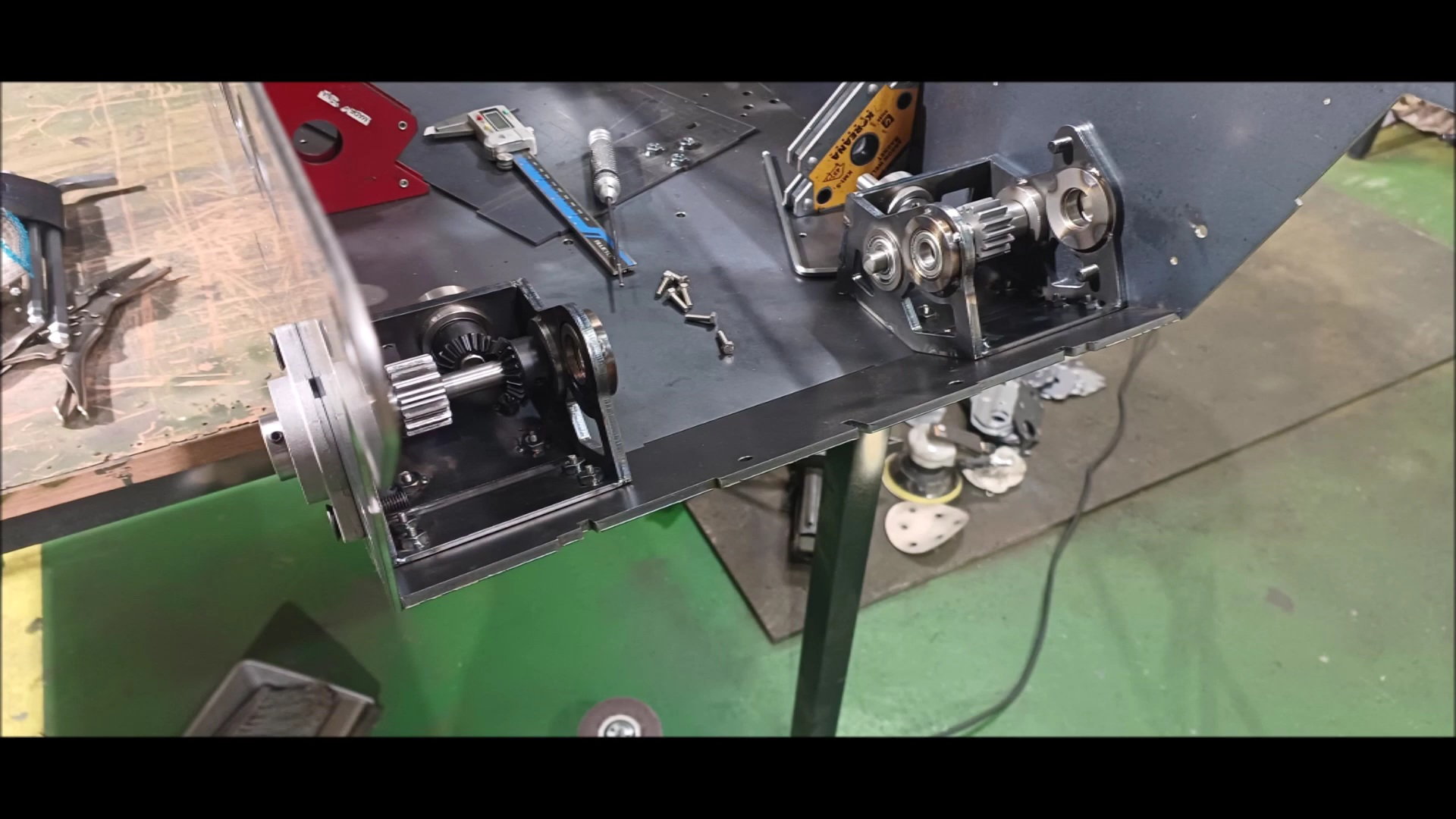

In this episode, body building begins. The body material is steel, and this work focuses on durability rather than detail, so it may have a slightly different shape from the actual vehicle.

Regards,

Young

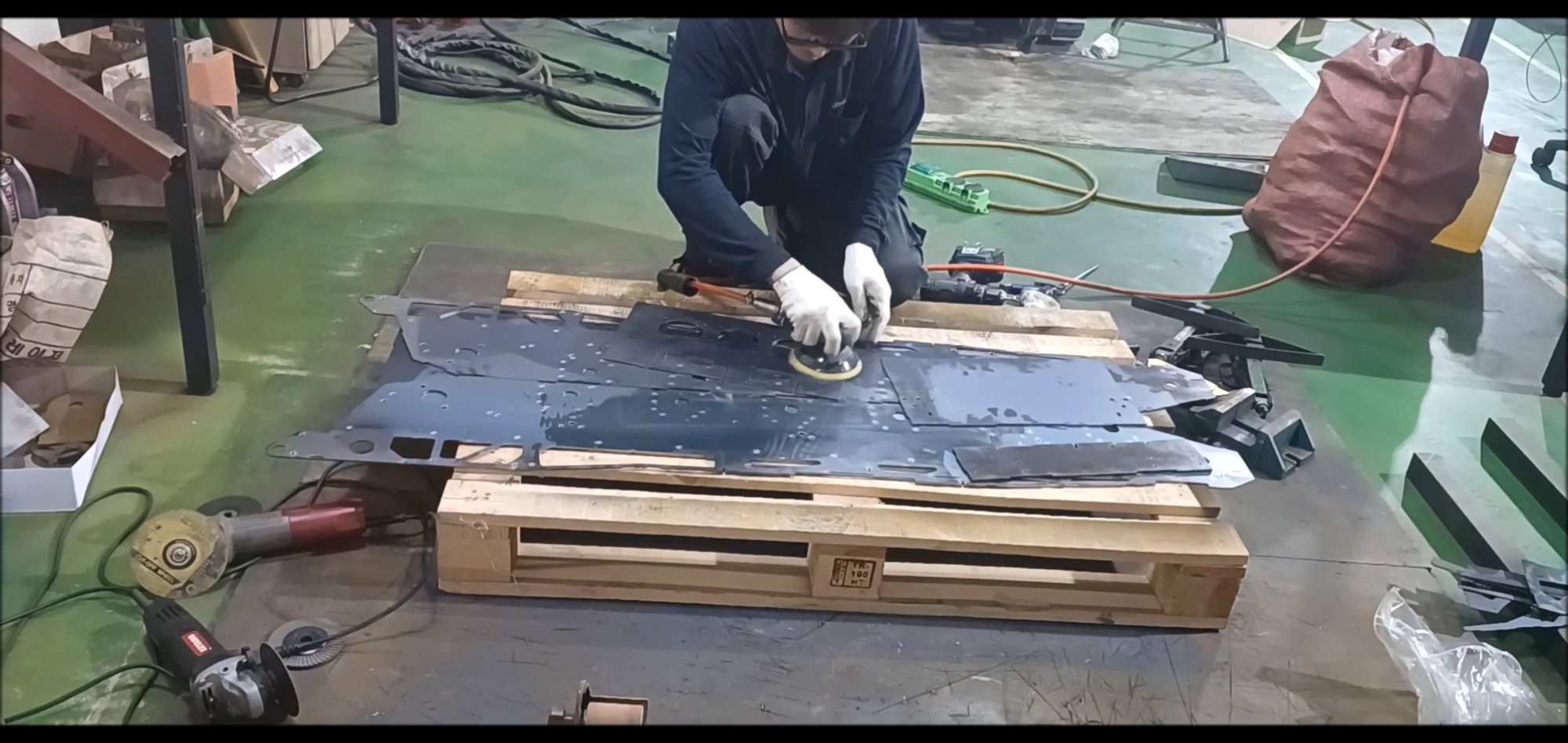

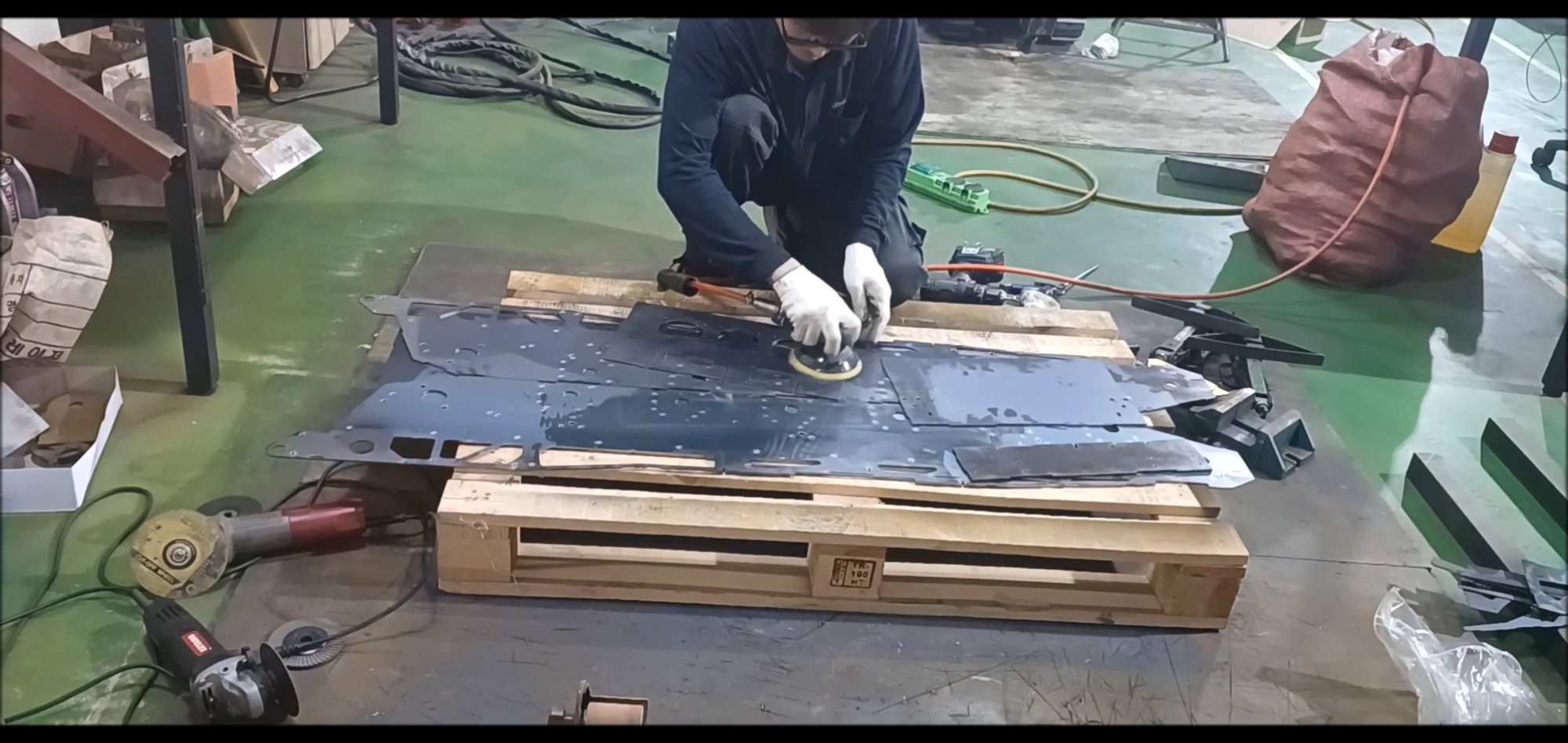

Transfer the pre-prepared body material to a temporary pallet for sink work and sanding work.

Every hole has a sink

Sink all holes without omission

Sink operation followed by a sanding operation on the surface

K2 Black Panther is different from left to right, so it makes a clear distinction

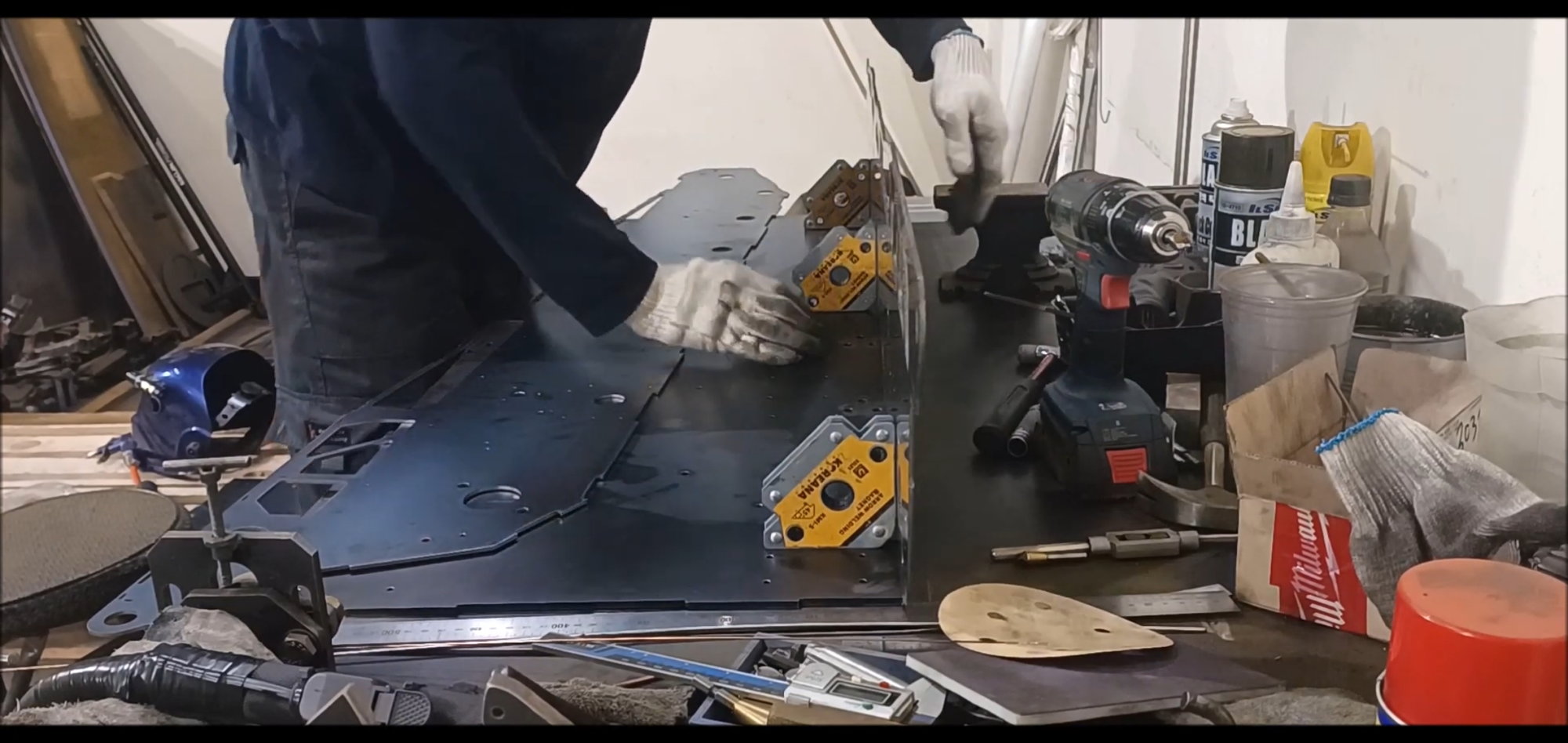

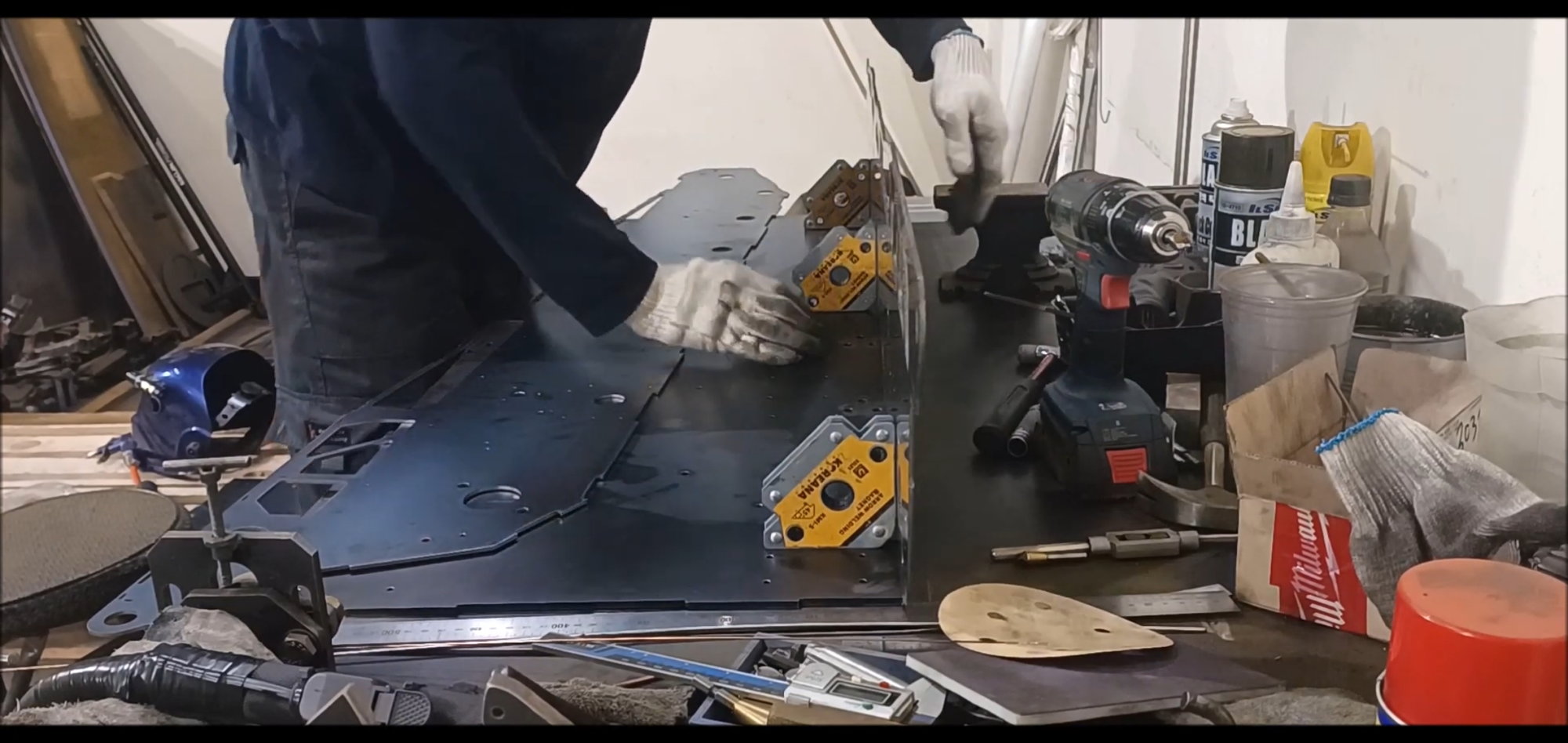

Move to workbench to verify configuration

Bolted the bottom of the body to reinforce the stress on the hole

A bolt is first welded by temporary welding

Bolt reinforcement is a work for durability rather than detail, which is different from real vehicles

Use a welding rod to weld reinforcement

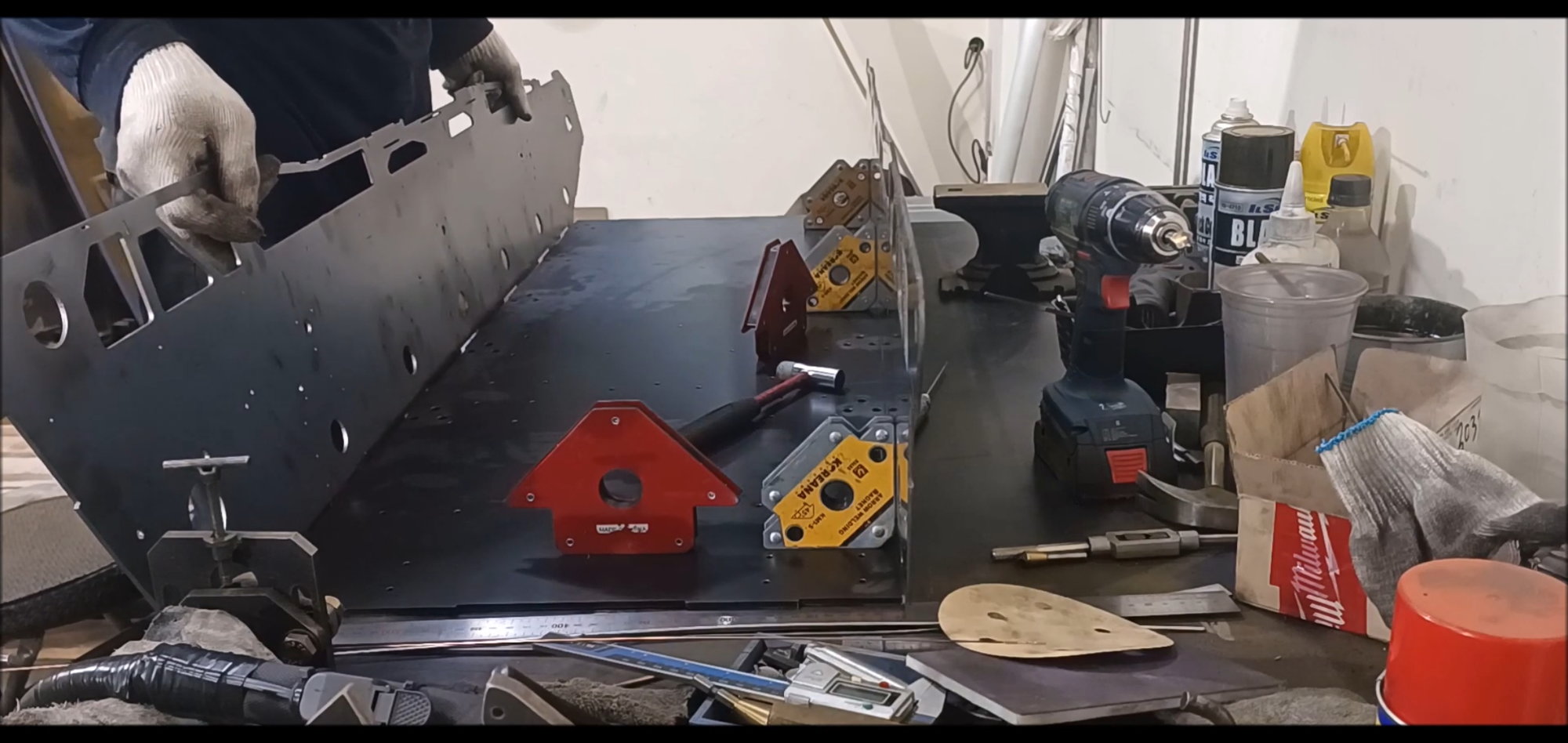

Install the side of the vehicle separately

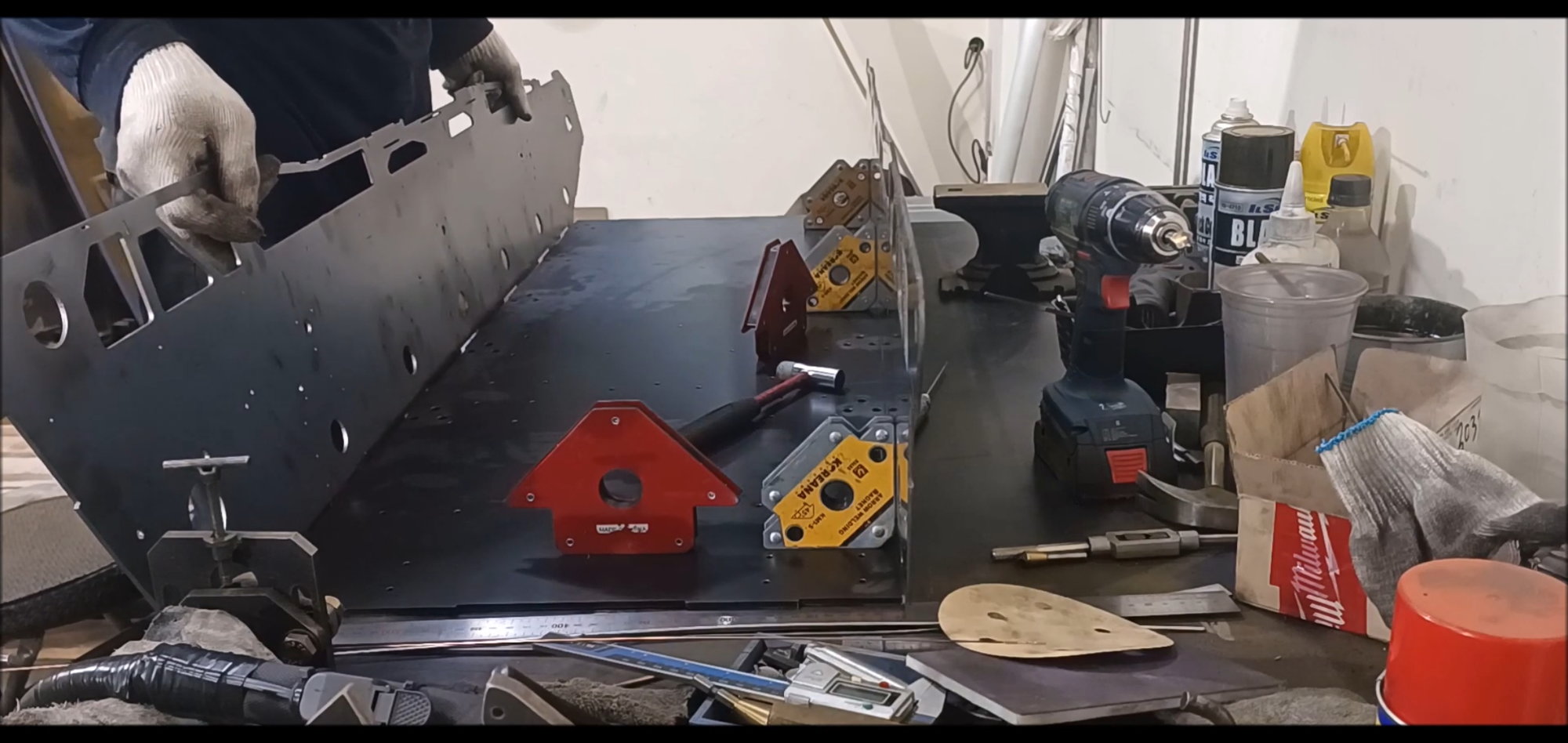

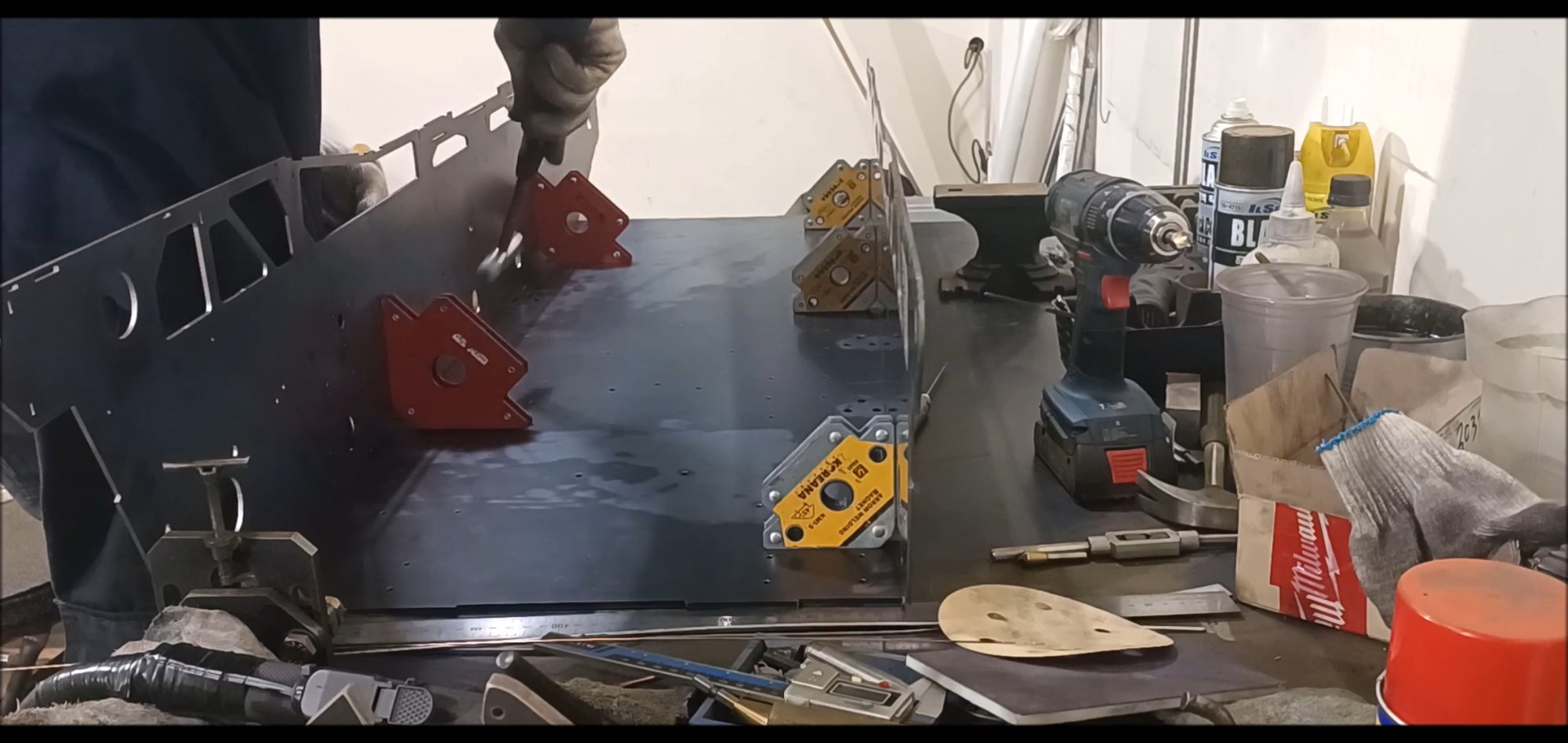

Construct geometry temporarily using a right angle magnet retainer

Construct geometry temporarily using a right angle magnet retainer

Hold the right angle and position

Check the front and rear body material

Check the front and rear body material

The gearbox must be manufactured first before the body can be welded

This week's work includes temporary configuration of features

Continue in the next episode.....

Regards,

Young

Transfer the pre-prepared body material to a temporary pallet for sink work and sanding work.

Every hole has a sink

Sink all holes without omission

Sink operation followed by a sanding operation on the surface

K2 Black Panther is different from left to right, so it makes a clear distinction

Move to workbench to verify configuration

Bolted the bottom of the body to reinforce the stress on the hole

A bolt is first welded by temporary welding

Bolt reinforcement is a work for durability rather than detail, which is different from real vehicles

Use a welding rod to weld reinforcement

Install the side of the vehicle separately

Construct geometry temporarily using a right angle magnet retainer

Construct geometry temporarily using a right angle magnet retainer

Hold the right angle and position

Check the front and rear body material

Check the front and rear body material

The gearbox must be manufactured first before the body can be welded

This week's work includes temporary configuration of features

Continue in the next episode.....

Last edited by PE YOUNG; 04-17-2023 at 02:20 PM.

The following users liked this post:

tankme (04-17-2023)

#45

Thread Starter

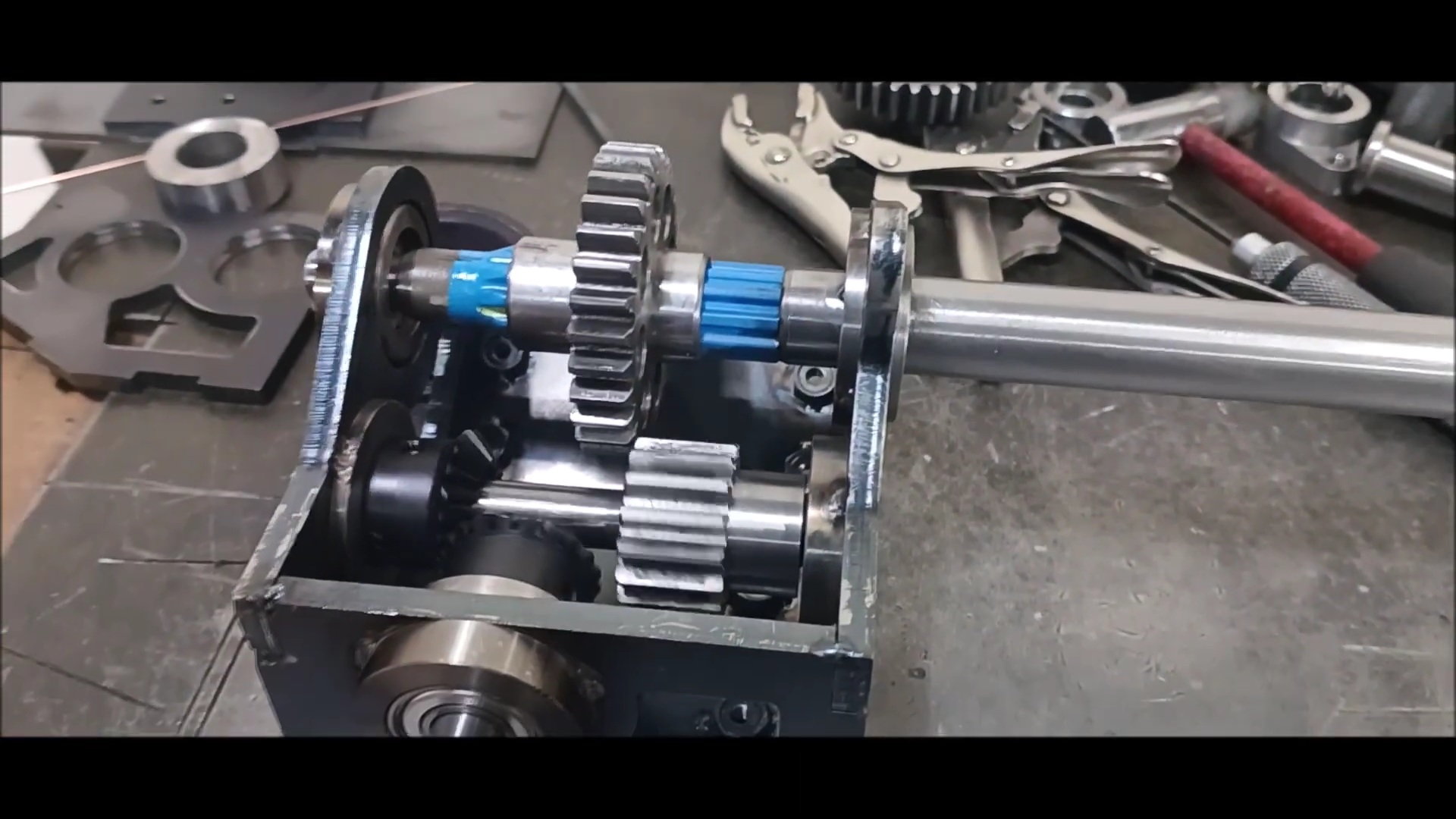

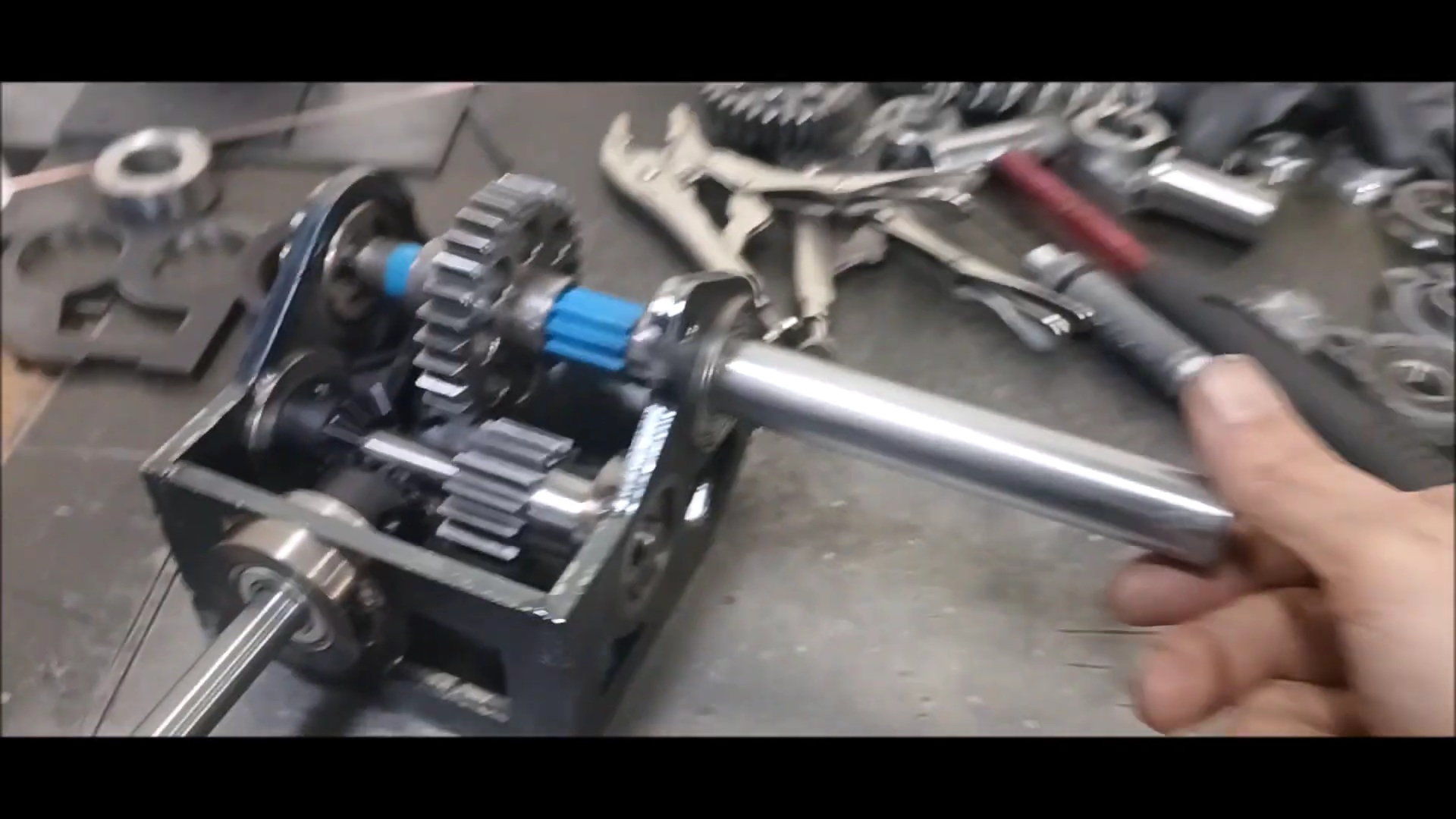

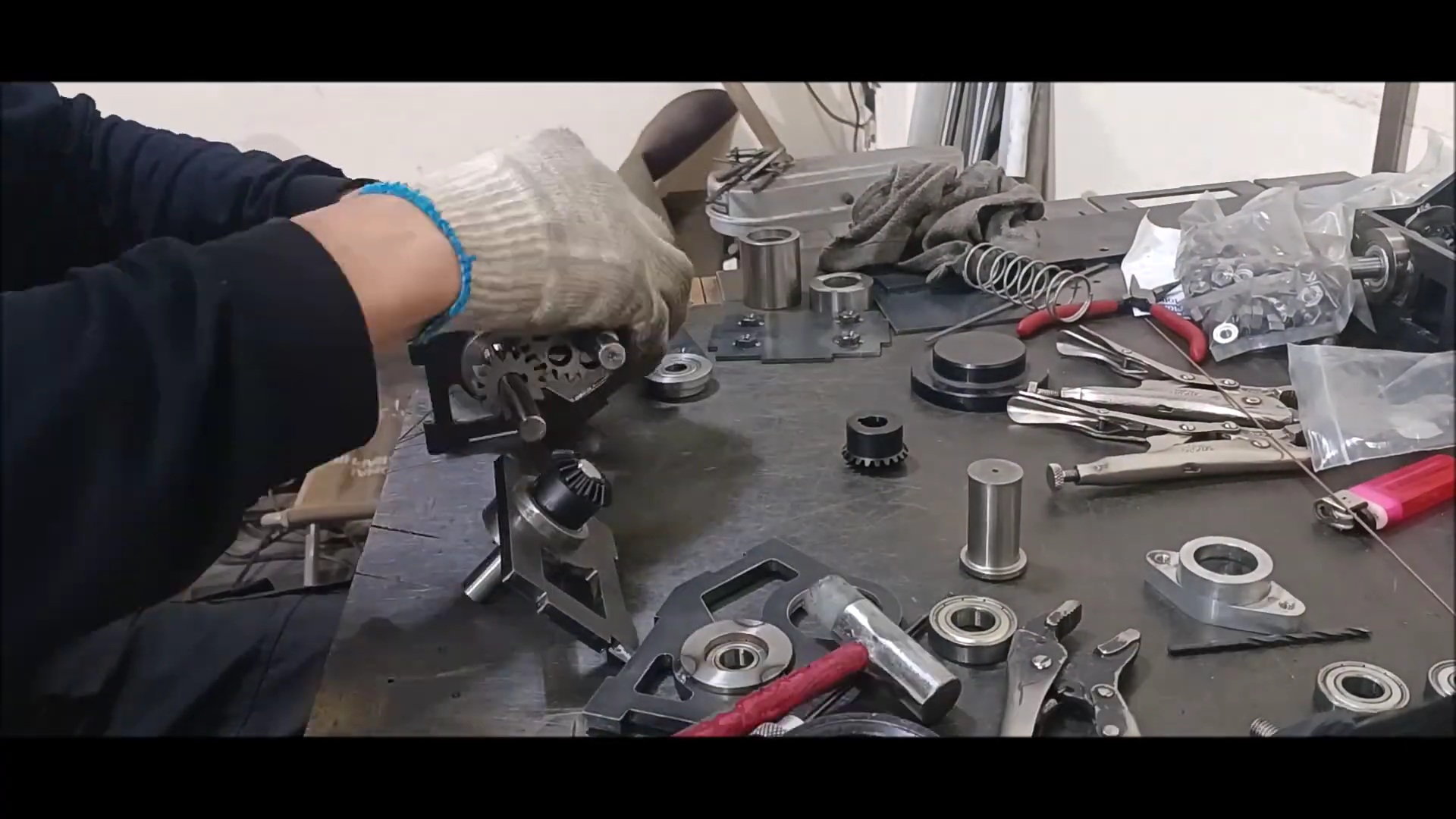

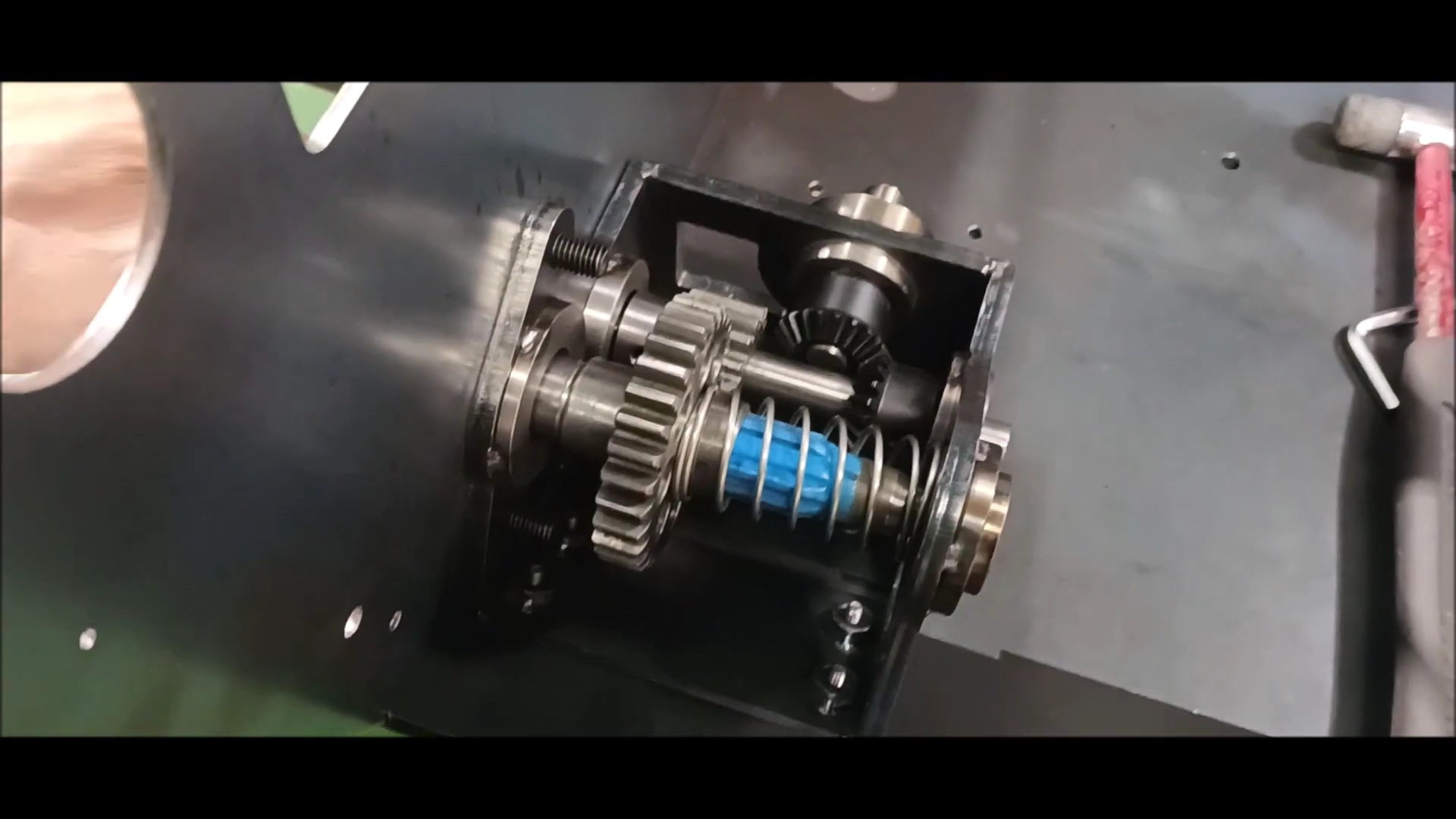

In this episode, a gear box for driving a sprocket will be manufactured, fixed to the left and right sides of the rear of the vehicle, and the gear for the turret in the middle of the vehicle body will be fixed

Regards,

Young

Laser-cut gearbox housing

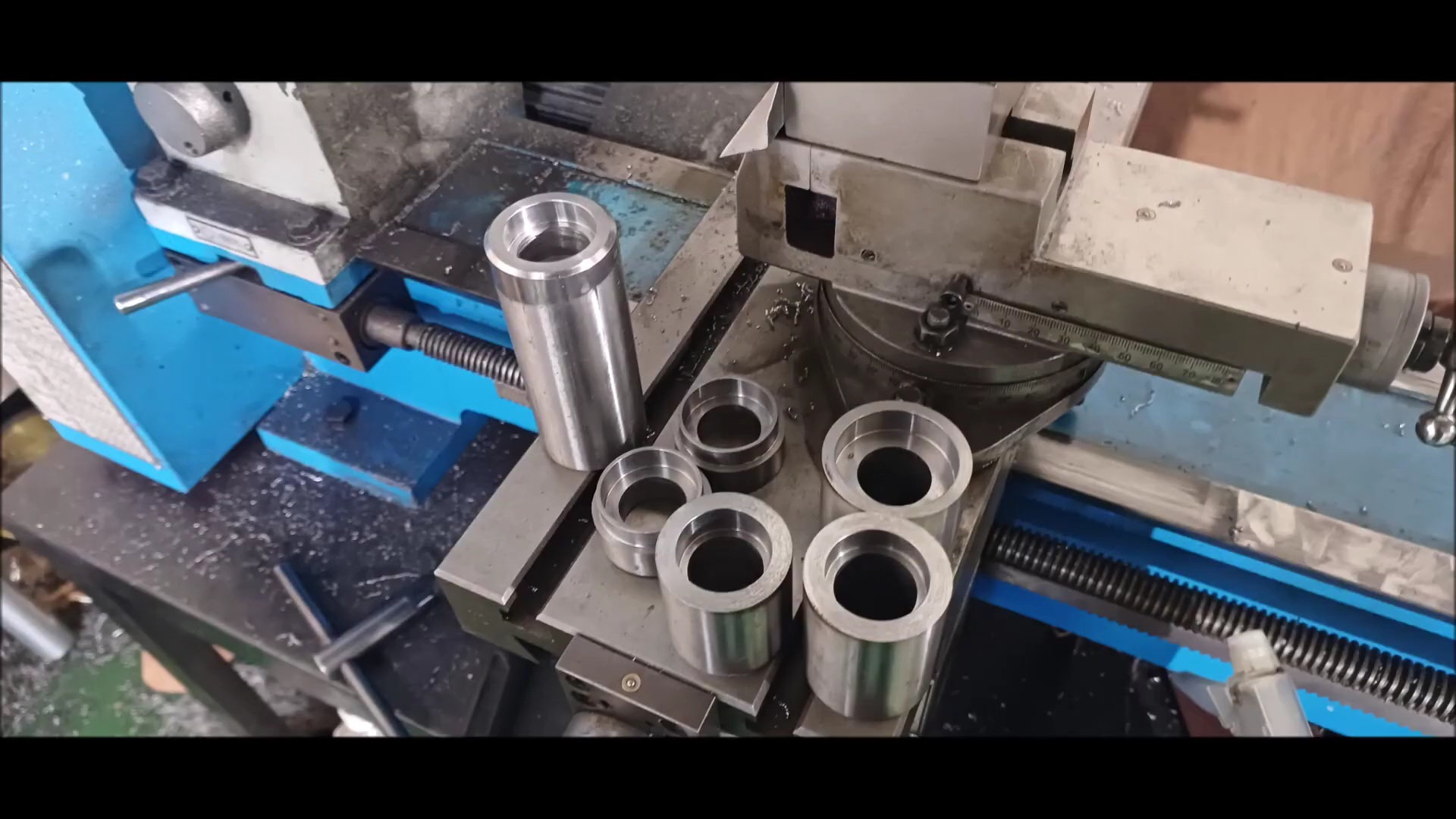

Check the number of bearing boxes and shafts required

Get ready for the round bar

Effective cutting can be done if there is a gap groove on the cutting machine blade

Measure the length of the cut using a steel ruler

round bar cutting

Bearing Housing Shelf Machine Work - 1

Bearing Housing Shelf Machine Work - 2

Bearing Housing Shelf Machine Work - 3

Bearing Housing Shelf Machine Work - 4

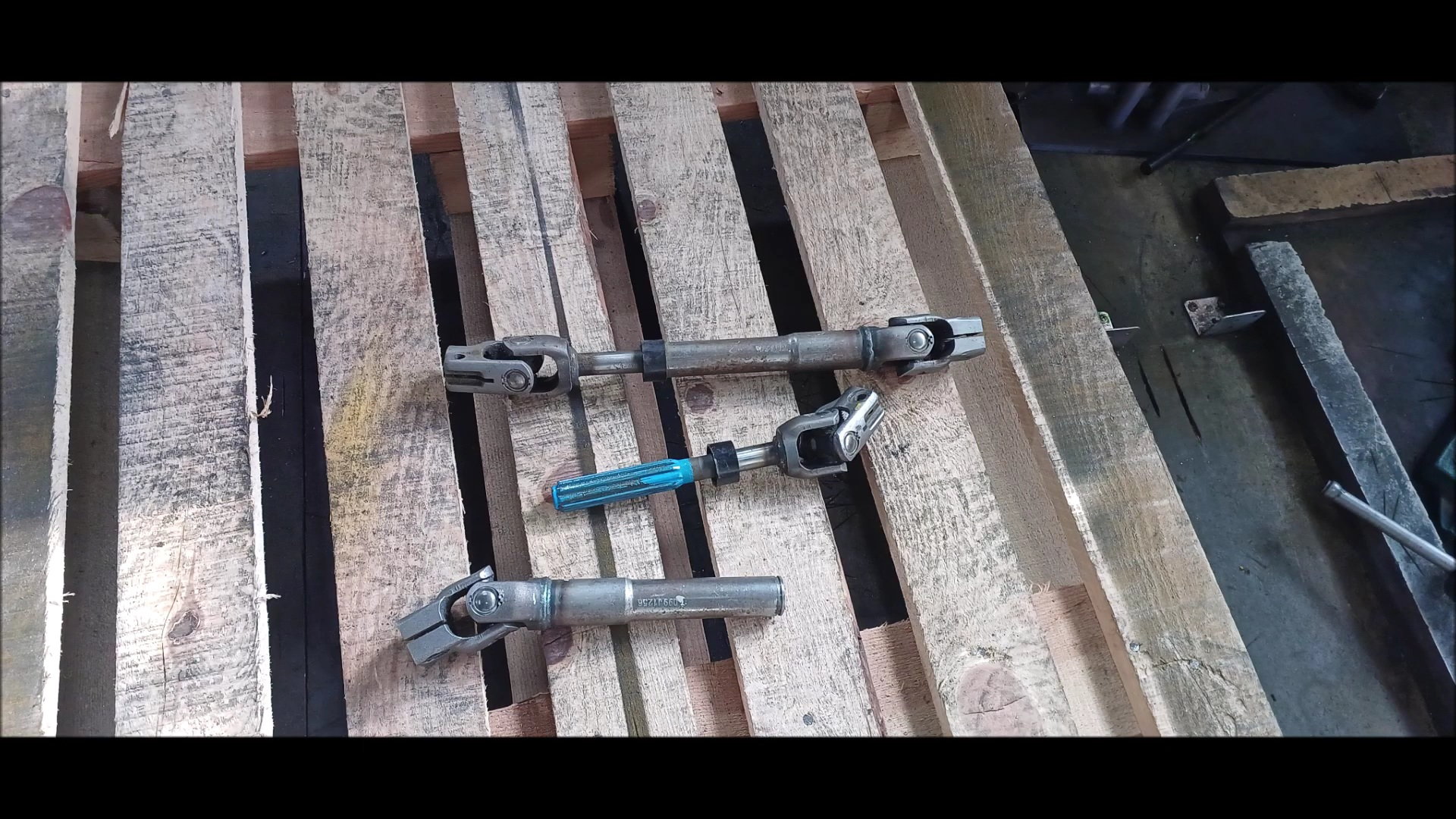

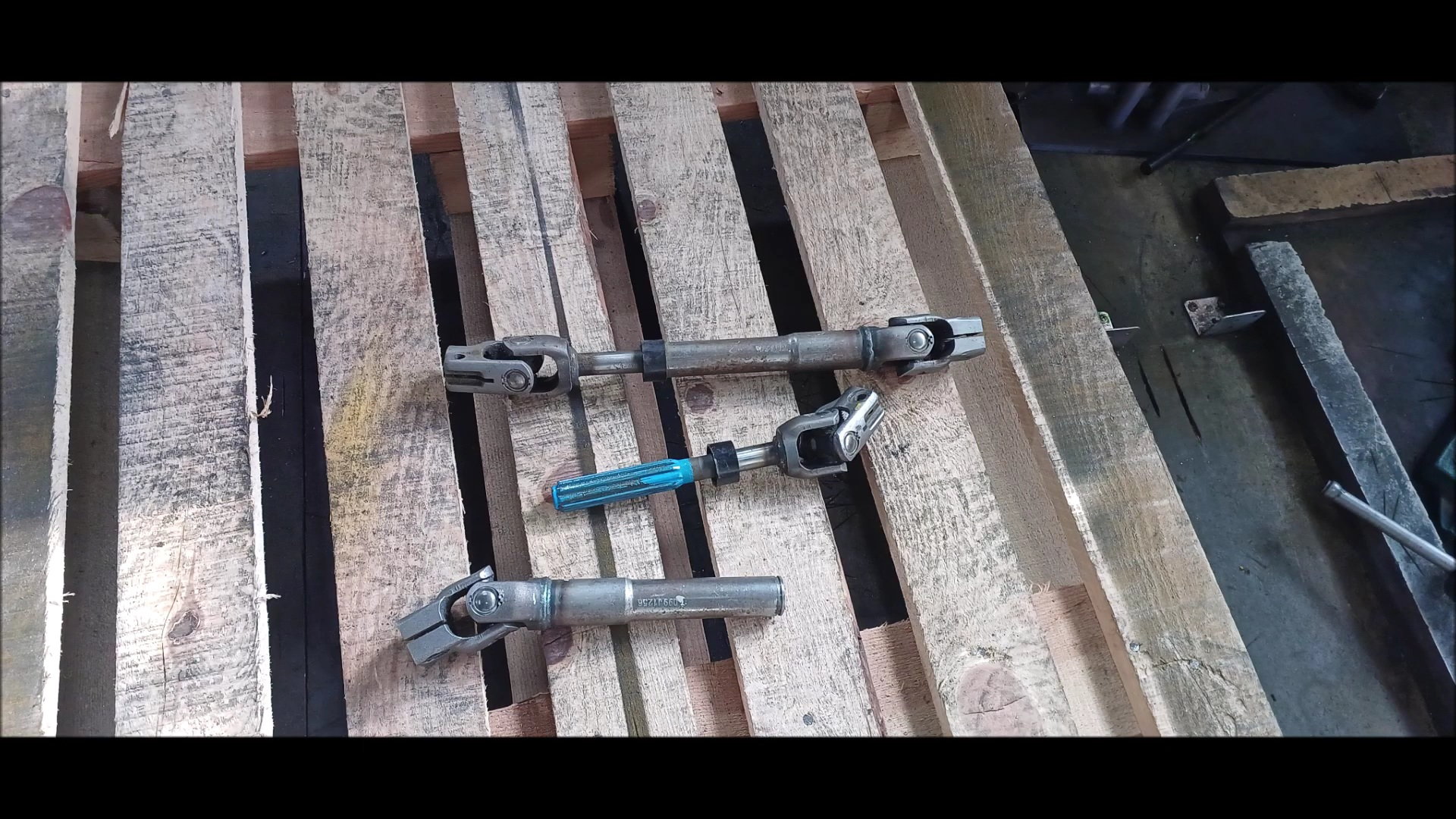

Preparation of constant speed joints from vehicle

use a spline

Round bar and welding for cut spline and drive shaft

a welded figure

Thermal deformation occurred while welding the spline coating part, but there is no problem with the operation of the snivel

Manufactured bearing housing

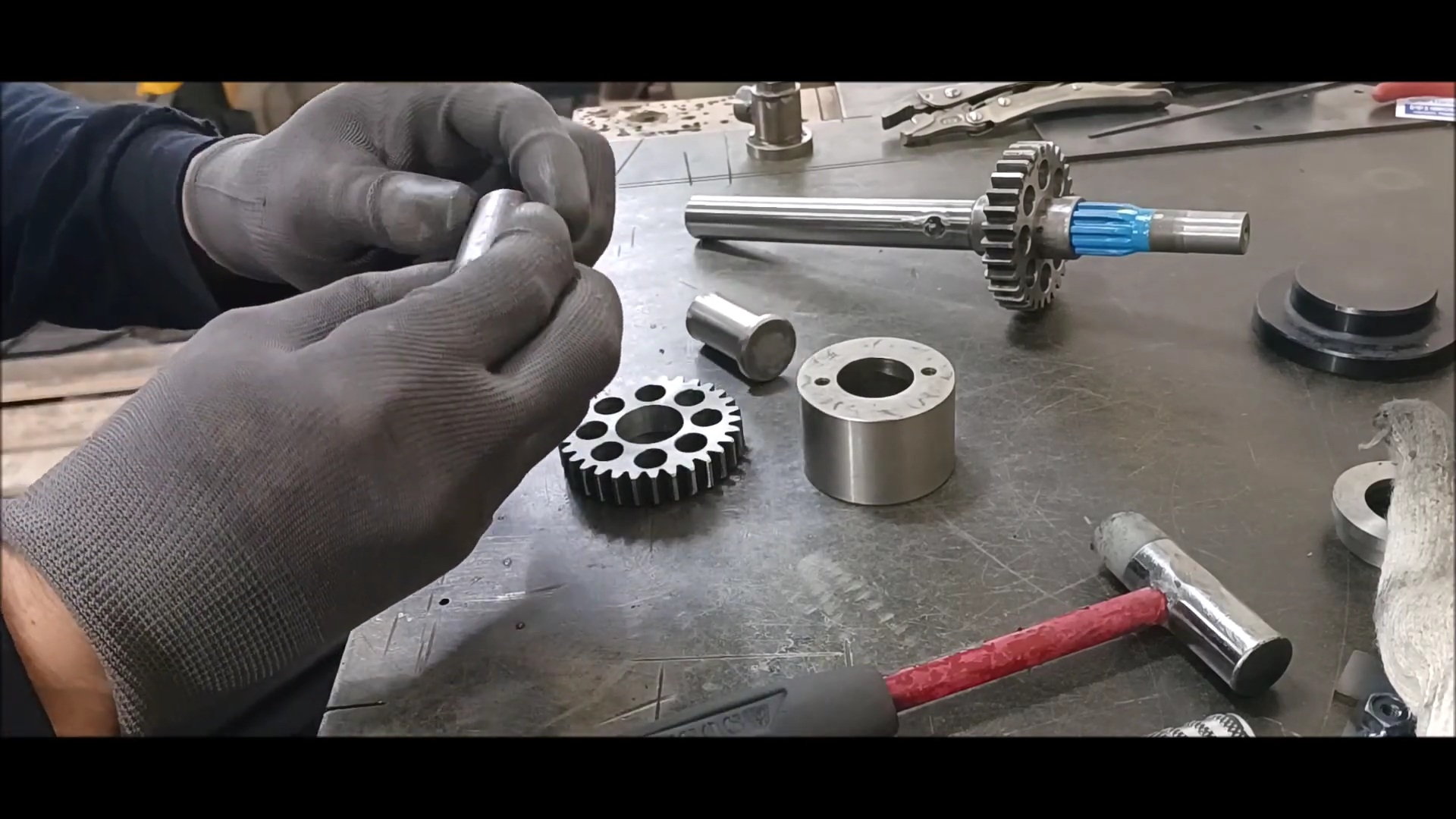

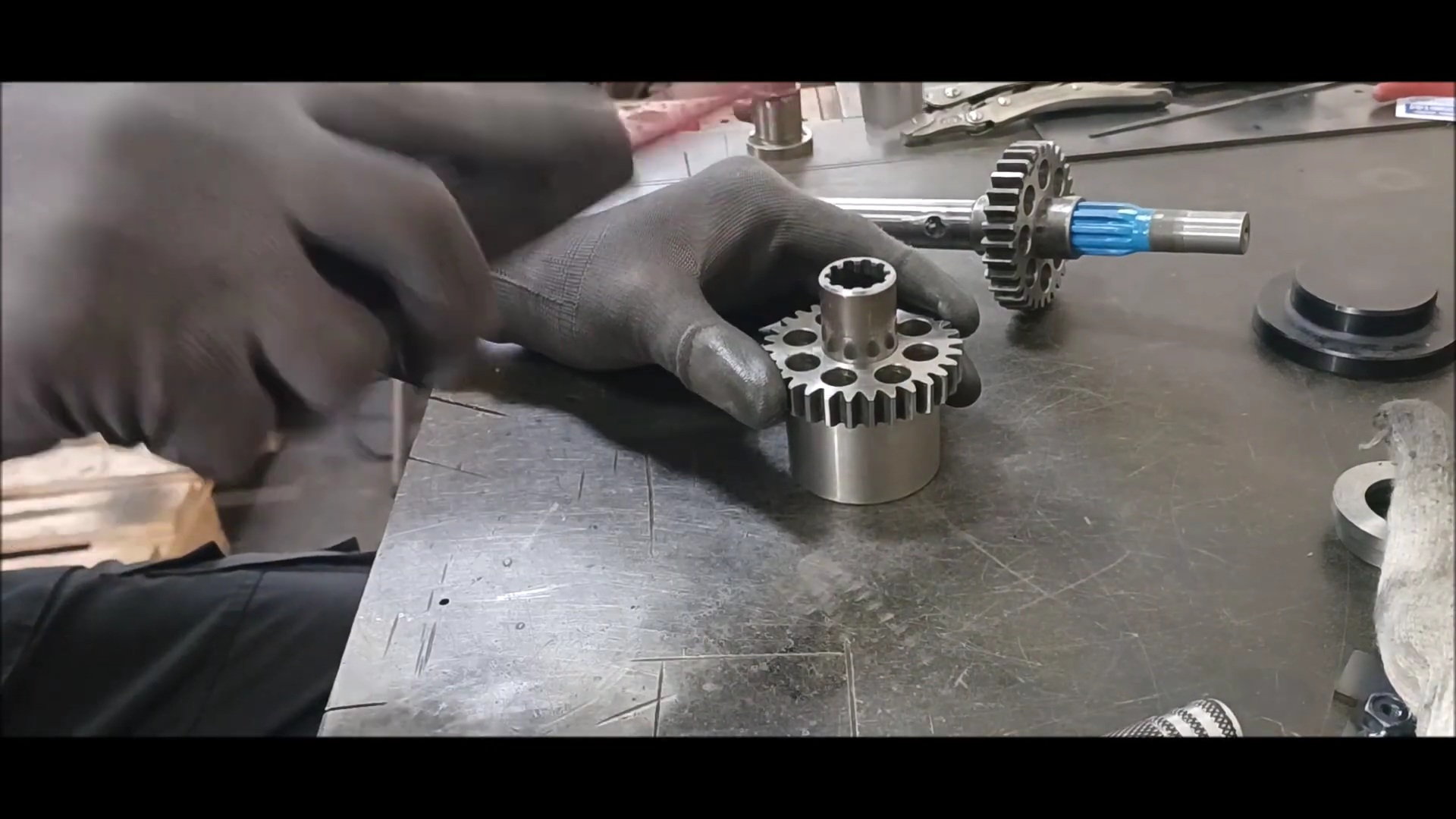

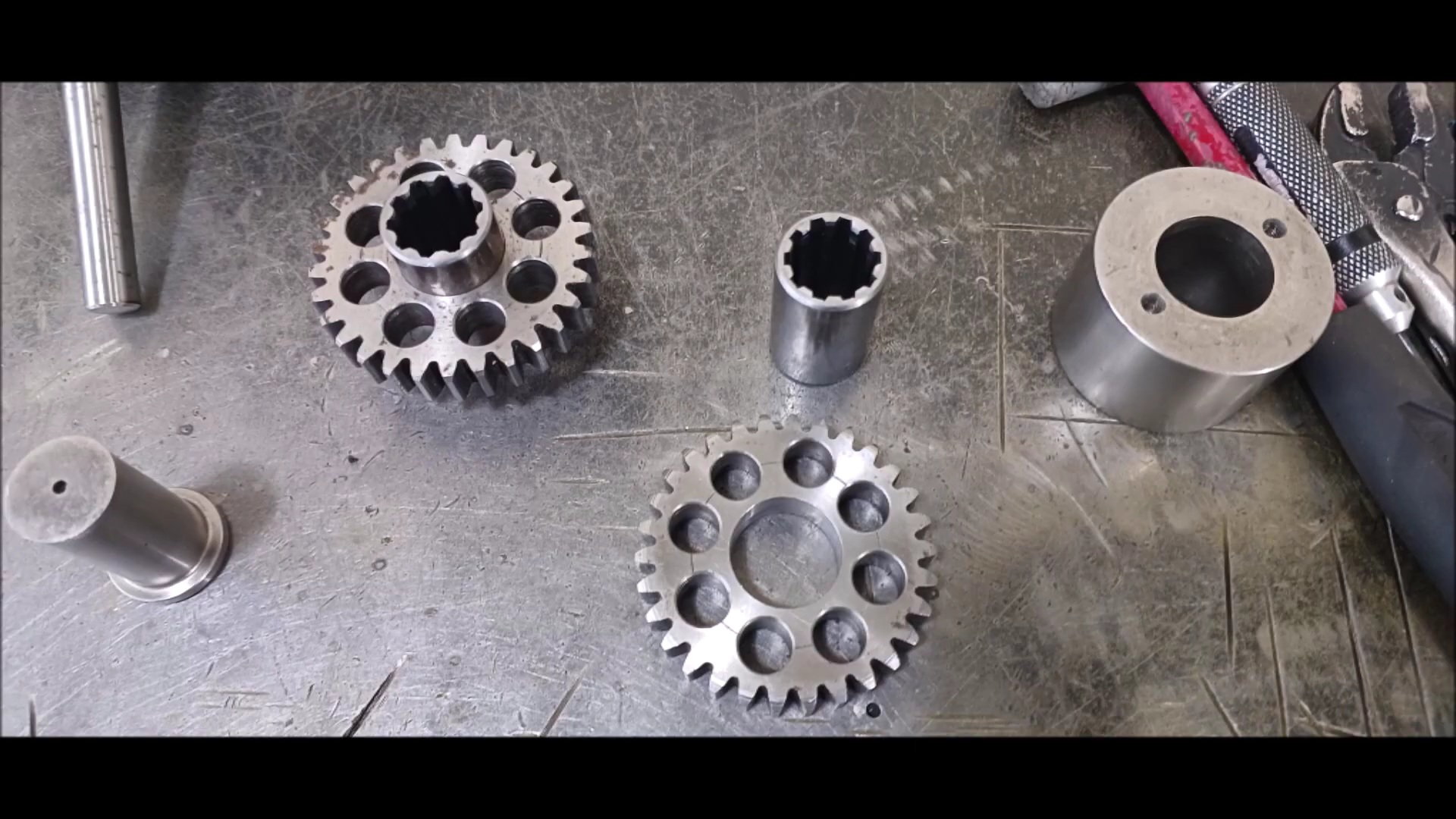

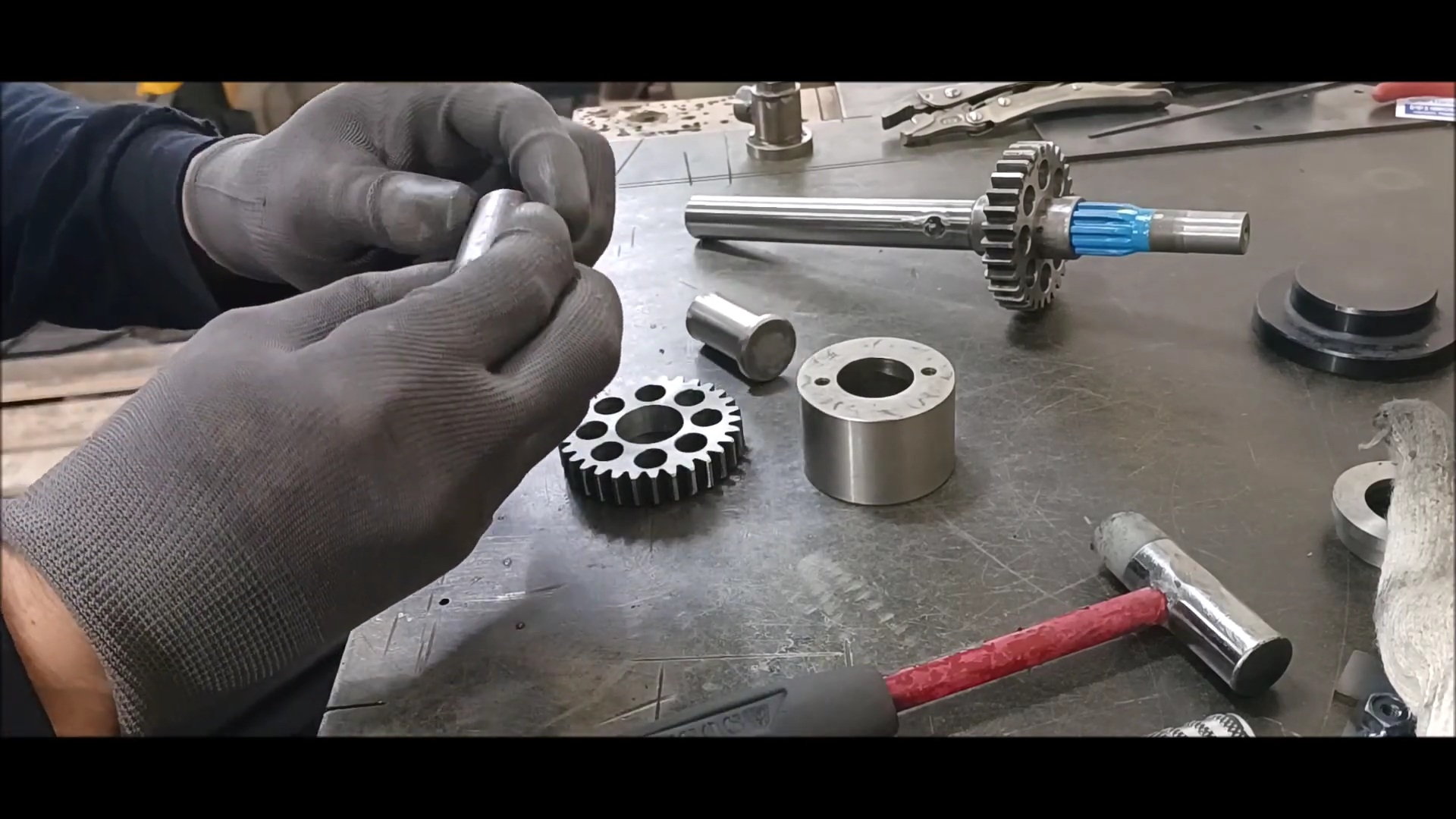

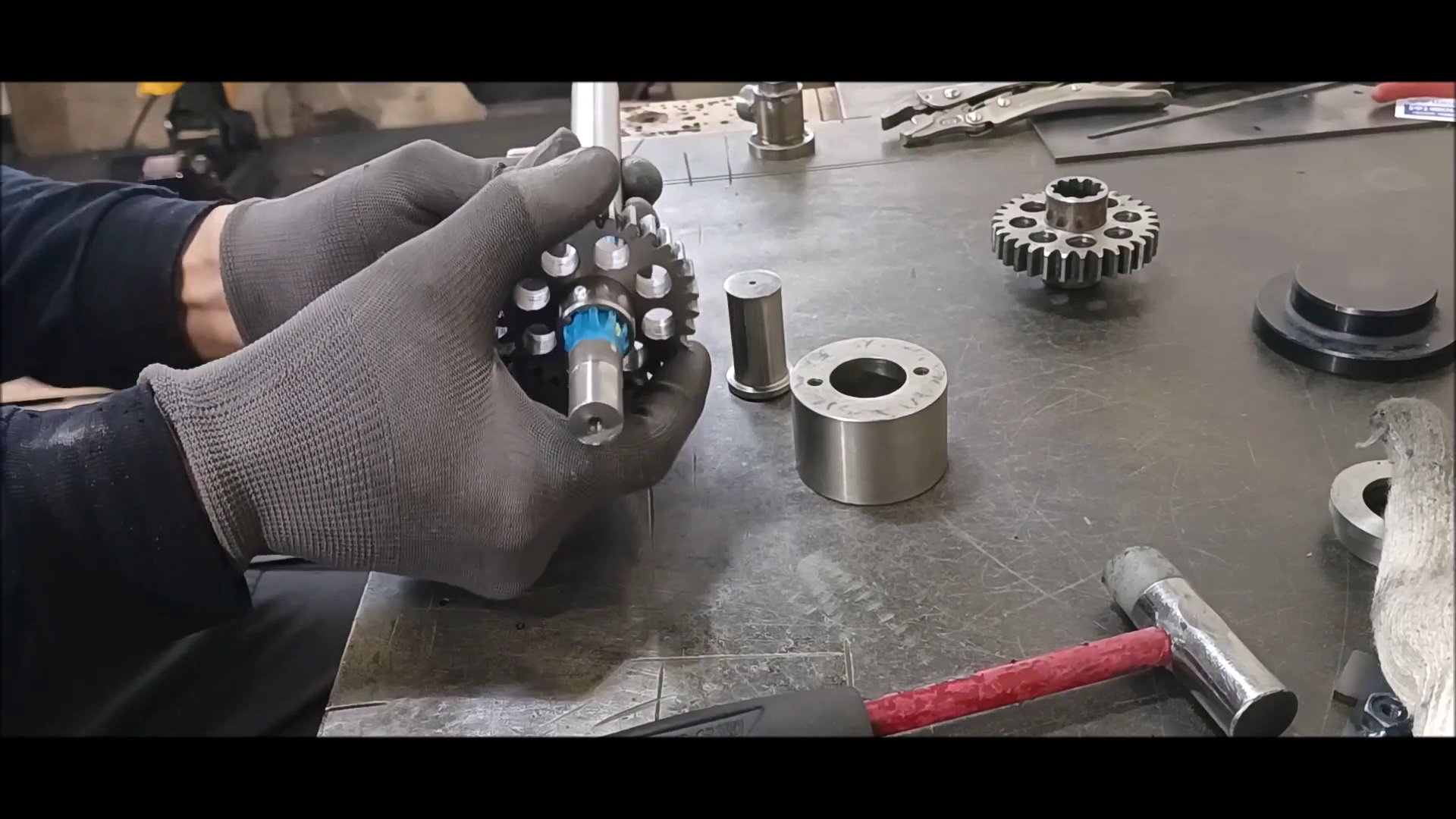

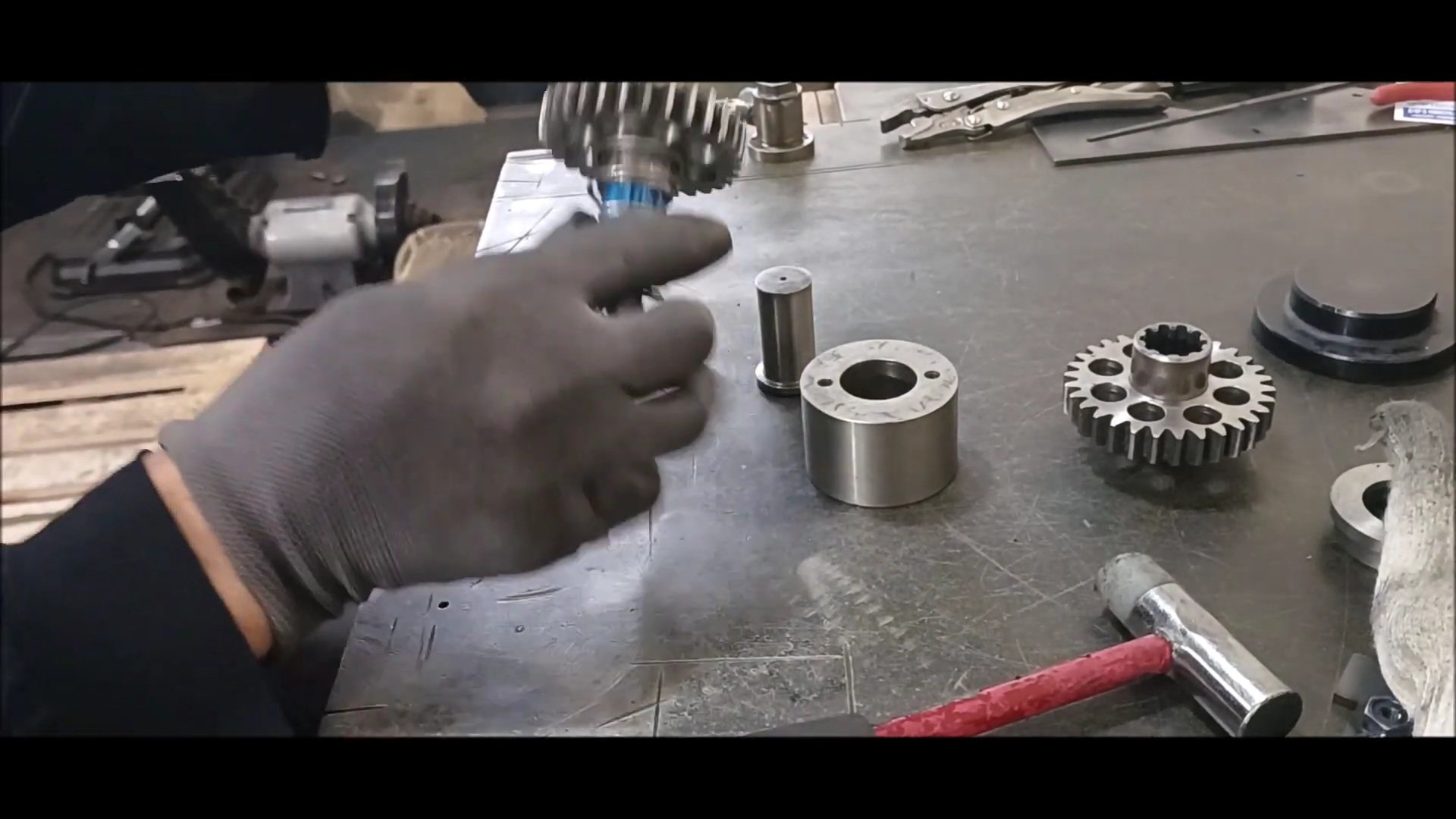

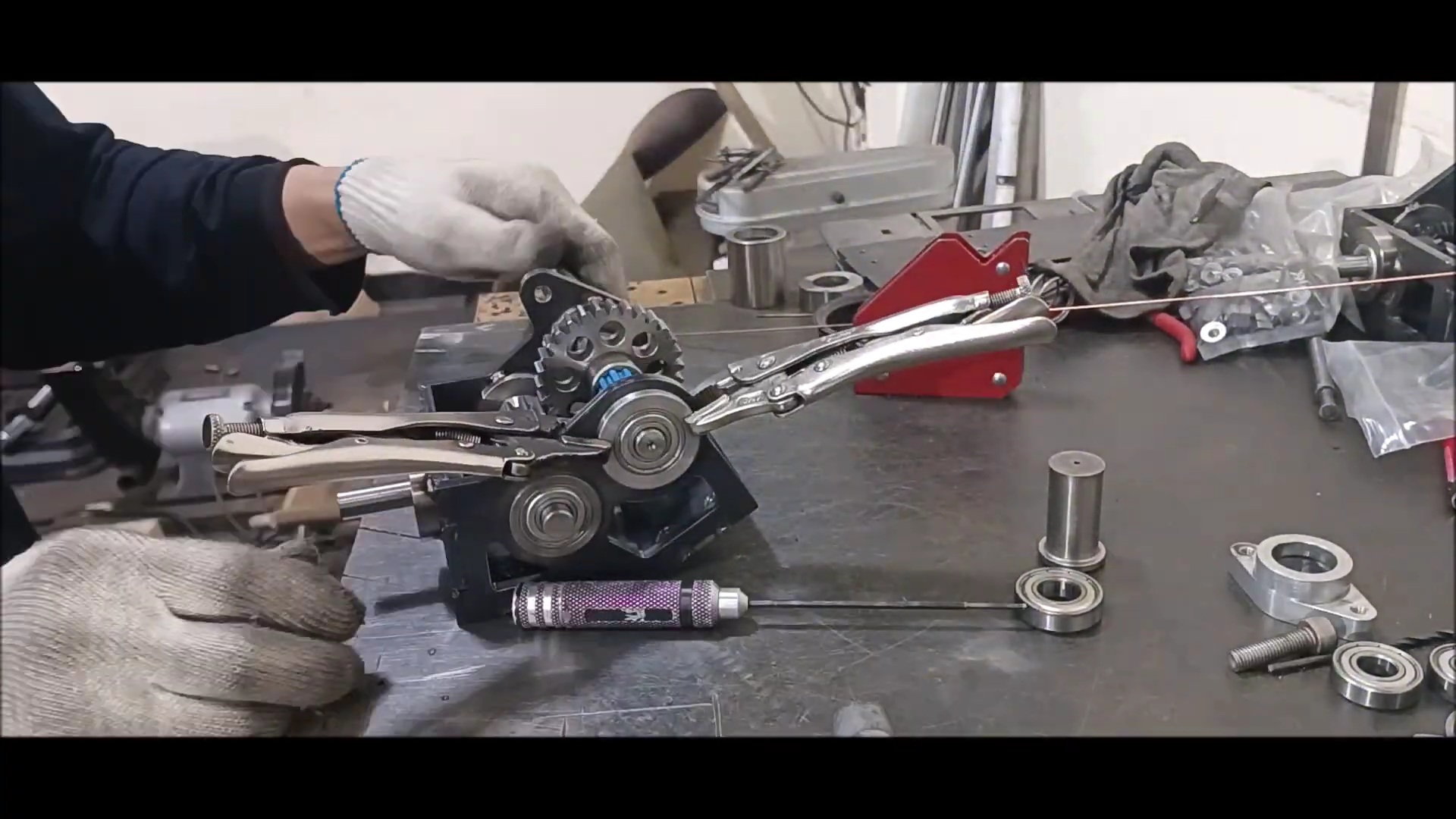

Gearbox assembly

Gearbox assembly

The last gear is a 2.5t module

sleeve to gear connection

Depth adjustment - 1

Depth adjustment - 2

Check the operation of spline

Check spring operation for manual neutral

Check the operation of the opposite spline gear

Regards,

Young

Laser-cut gearbox housing

Check the number of bearing boxes and shafts required

Get ready for the round bar

Effective cutting can be done if there is a gap groove on the cutting machine blade

Measure the length of the cut using a steel ruler

round bar cutting

Bearing Housing Shelf Machine Work - 1

Bearing Housing Shelf Machine Work - 2

Bearing Housing Shelf Machine Work - 3

Bearing Housing Shelf Machine Work - 4

Preparation of constant speed joints from vehicle

use a spline

Round bar and welding for cut spline and drive shaft

a welded figure

Thermal deformation occurred while welding the spline coating part, but there is no problem with the operation of the snivel

Manufactured bearing housing

Gearbox assembly

Gearbox assembly

The last gear is a 2.5t module

sleeve to gear connection

Depth adjustment - 1

Depth adjustment - 2

Check the operation of spline

Check spring operation for manual neutral

Check the operation of the opposite spline gear

Last edited by PE YOUNG; 04-23-2023 at 02:03 PM.

#47

Thread Starter

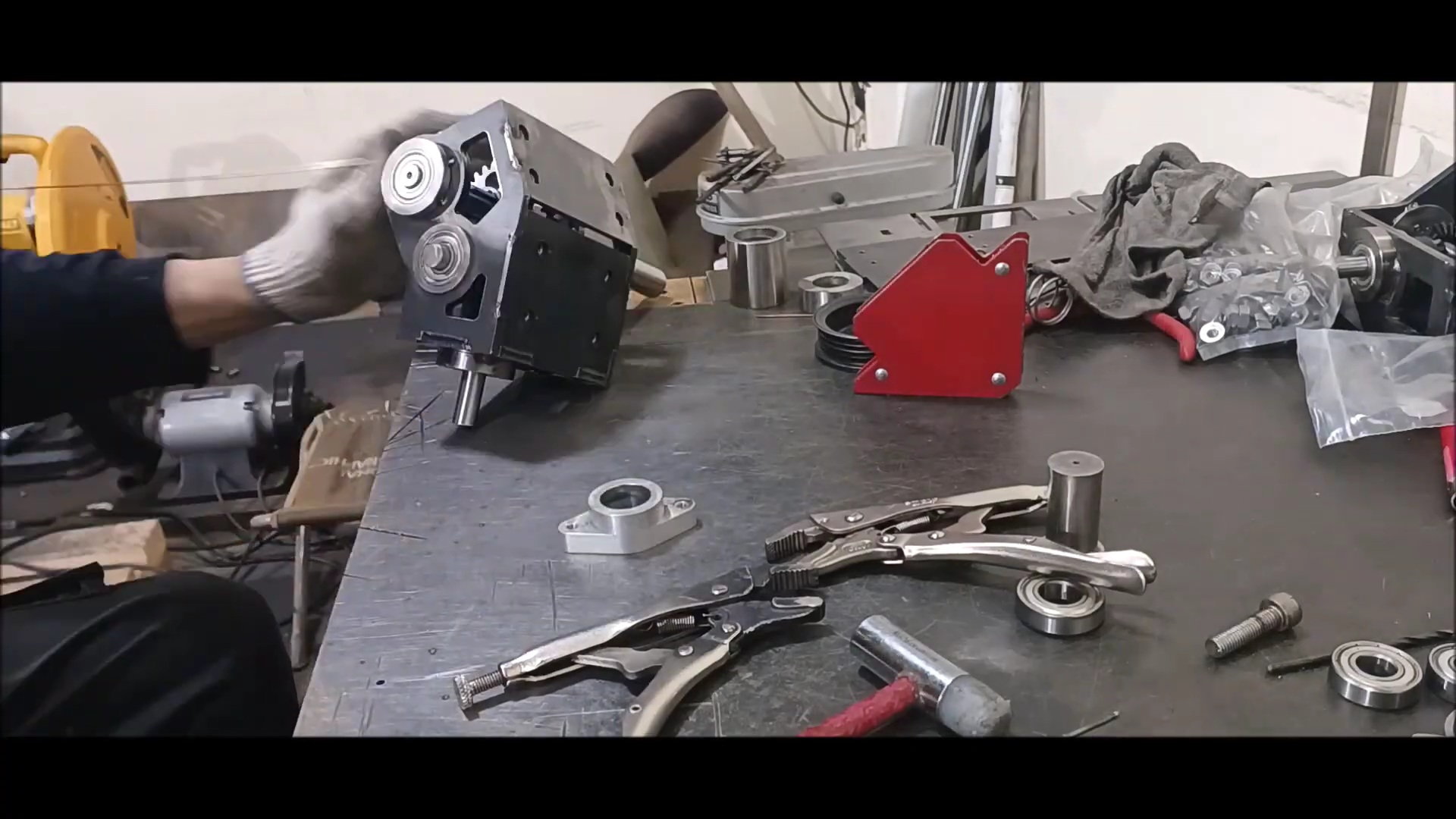

Assembled gearbox shape

Spline gear decoupled

Gearbox Fabrication - 01

Gearbox Fabrication - 02

Gearbox Fabrication - 03

Gearbox Fabrication - 04

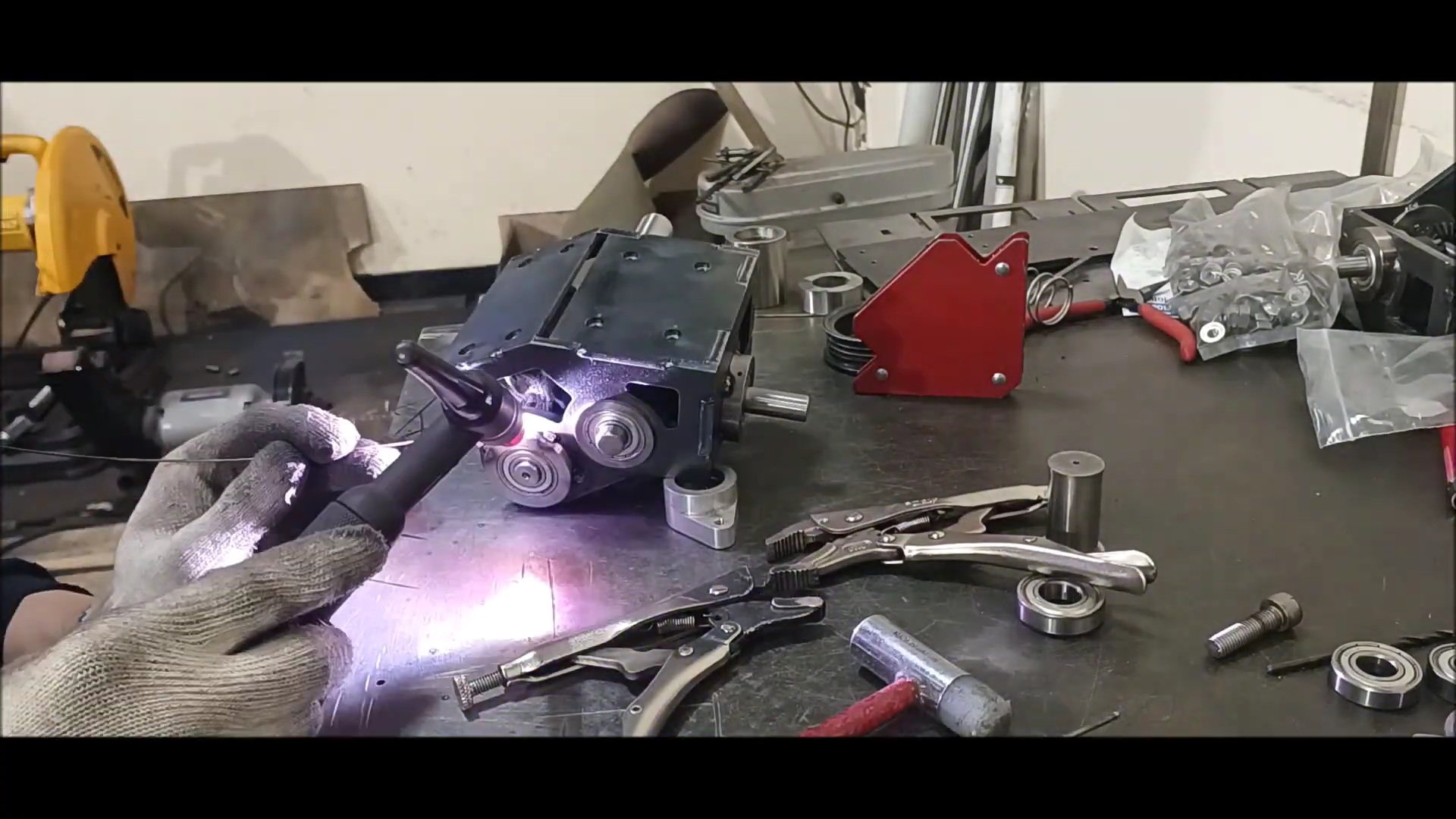

Gearbox Fabrication - 05 [Bearing Insertion with Welded Heat]

Gearbox Fabrication - 06

Gearbox Fabrication - 07

Gearbox Fabrication - 08

Gearbox Fabrication - 09

Gearbox Fabrication - 10

Gearbox Fabrication - 11

Gearbox Fabrication - 12

Gearbox Fabrication - 13

Gearbox Fabrication - 14

Gearbox Fabrication - 15

Gearbox Fabrication - 16

Gearbox Fabrication - 17

Gearbox Fabrication - 18

Gearbox Fabrication - 19

Gearbox Fabrication - 20

Gearbox Fabrication - 21

Gearbox Fabrication - 22

Gearbox Fabrication - 23

#48

Thread Starter

Gearbox Fabrication - 24

Gearbox Fabrication - 25

rbox Fabrication - 26

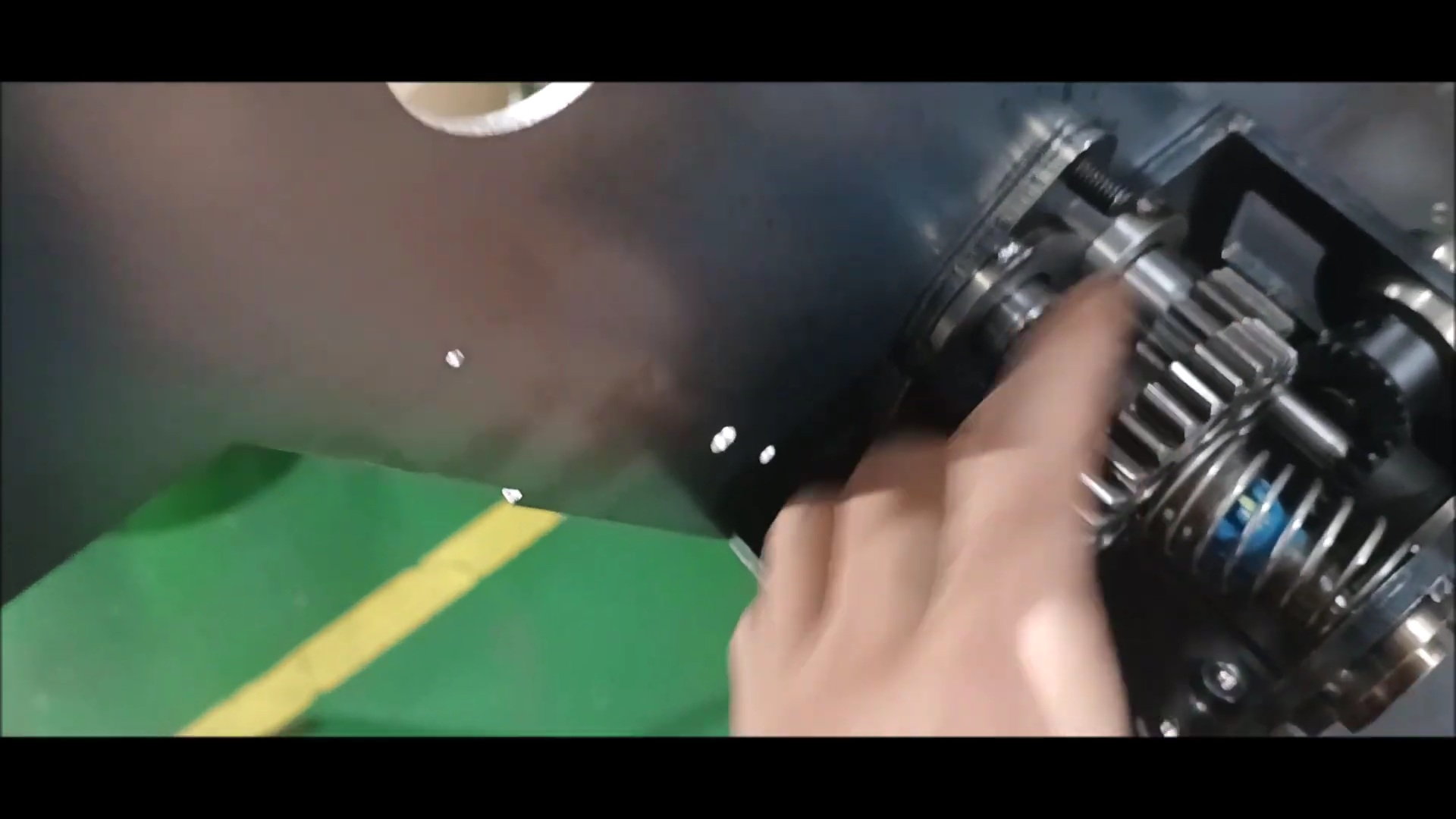

left and right complete gearbox

left and right complete gearbox [The neutral spring is out]

Positioned on the rear of the body

Positioned on the rear of the body

Prepare to secure to the side of the body

Fix it in an irin fashion

Go to the left and right side plates

Secure the bolt by positioning it

Fix the rear lower plate

Fix the rear lower plate

Fix the rear lower plate

Setting the turret bearing position

Setting the turret bearing position

Setting the turret bearing position

Gearbox complete

Manual Neutral Test

Manual Neutral Test

Manual Neutral Test

Manual Neutral Test

Manual Neutral Test

In the next episode, body welding will proceed