1/5 scale K2 black panther tank

#1

Thread Starter

I will share the manufacturing process of this tank.

I would like to share a series of processes to produce the K2 Black Panther, the main tank of the Korean Army, on a 1/5 scale.

This work is produced in a desert version, not a standard model of the Korean Army.

Therefore, the model also has an additional air-conditioned outdoor unit installed in the turret.

Regards,

Young

Last edited by PE YOUNG; 03-02-2023 at 07:18 PM.

The following users liked this post:

Panther F (03-04-2023)

#2

Thread Starter

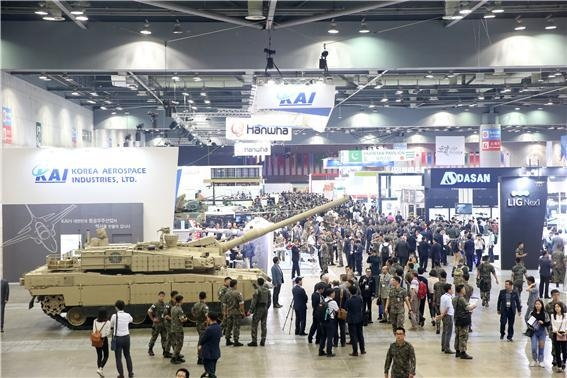

To get the information of the tank, I first observed the photos of the exhibition.

The tanks will be powered by engines and are being built using steel, aluminum and some plastic materials. The production process will be shared once a week and completed within 25 to 30 weeks.

Regards,

Young

Last edited by PE YOUNG; 03-03-2023 at 01:38 PM.

The following users liked this post:

Pcomm1.v2 (07-19-2023)

#3

In 1/5 scale that's going to be a very large tank. I'll be looking forward to seeing the process unfold as this thing comes to fruition. It's also an opportunity for me to pass on a little information. The conservation and preservation of our big cats is a personal passion of mine. That's why I know that there's actually no such thing as a black panther. Black panther is just a catch-all term that's used to describe any big cat with a black coat. What people call black panthers are usually leopards or Jaguars that have a genetic defect that makes the fur appear solid black, but if you look very close so you can still see the spots. Leopards and Jaguars are very opportunistic and very adaptable and that's why they're doing better than lions or tigers. My very favorite, the cheetah, is technically not a big cat and that's the lesson for today, what is and is not a big cat? It's pretty simple really, in order to qualify for the big cat club, you must have the ability to roar, and you must not have the ability to purr. Lions, tigers, leopards and Jaguars are the only cats that can roar and are the only cats that are considered to be true big cats. Personally, I don't think that's entirely fair, I think cheetahs and mountain lions should also be included as big cats, but neither can roar and they both can purr. If you've ever seen the video, a 150 lb mountain lion purring is a pretty amazing thing to see. So I hope you guys will remember, if we don't start to care about these wonderful and Majestic animals we're going to lose them. Do you want to be the person that has to tell your grandchildren that we used to have lions and tigers but we don't anymore because nobody cared? Sorry to go off topic like that, but like I said, this is a real passion with me. If people don't start to give a crap, these Regal mammals will go extinct in our lifetimes. Just something to think about.

#5

Thread Starter

First of all, the name of the project to build a 1/5 scale model of the 2023 K2 Black Panther was set as is2504.

The work that is the basis for the fabrication of the model tank begins with a caterpillar.

The new model will be powered by a combination of a 35cc gasoline engine and a hydraulic motor, which will weigh more than the 2022 version.

Therefore, the caterpillar production method was produced by converting from a method that emphasizes detail to a method that is durable and easy to repair.

The structure of the caterpillar consists of a shoe body, a rubber pad guide, a center guide, and a connecting pin, and a rubber pad will be attached to the lower part.

Please refer to the following YouTube video for the production process, and the photo below is captured from the YouTube video.

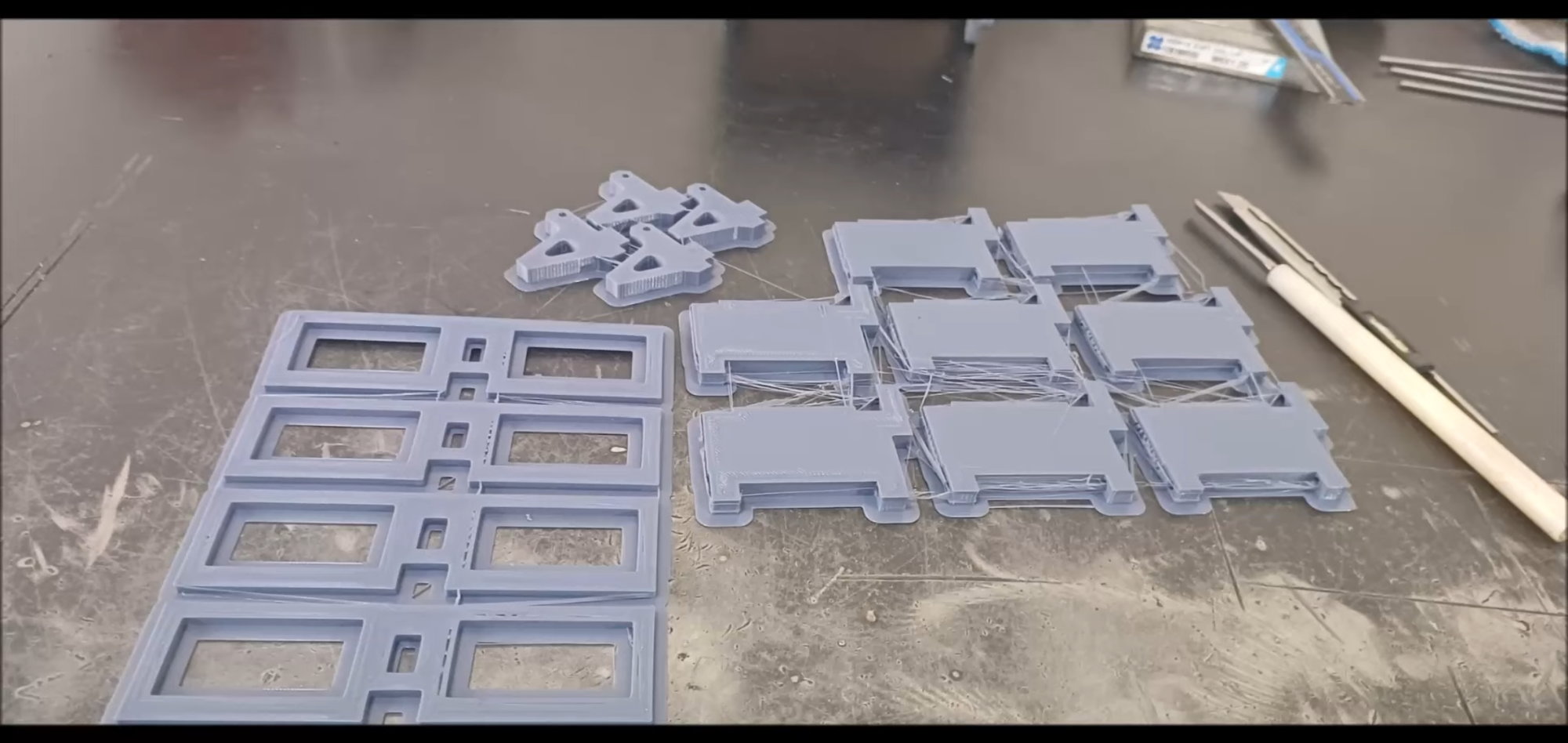

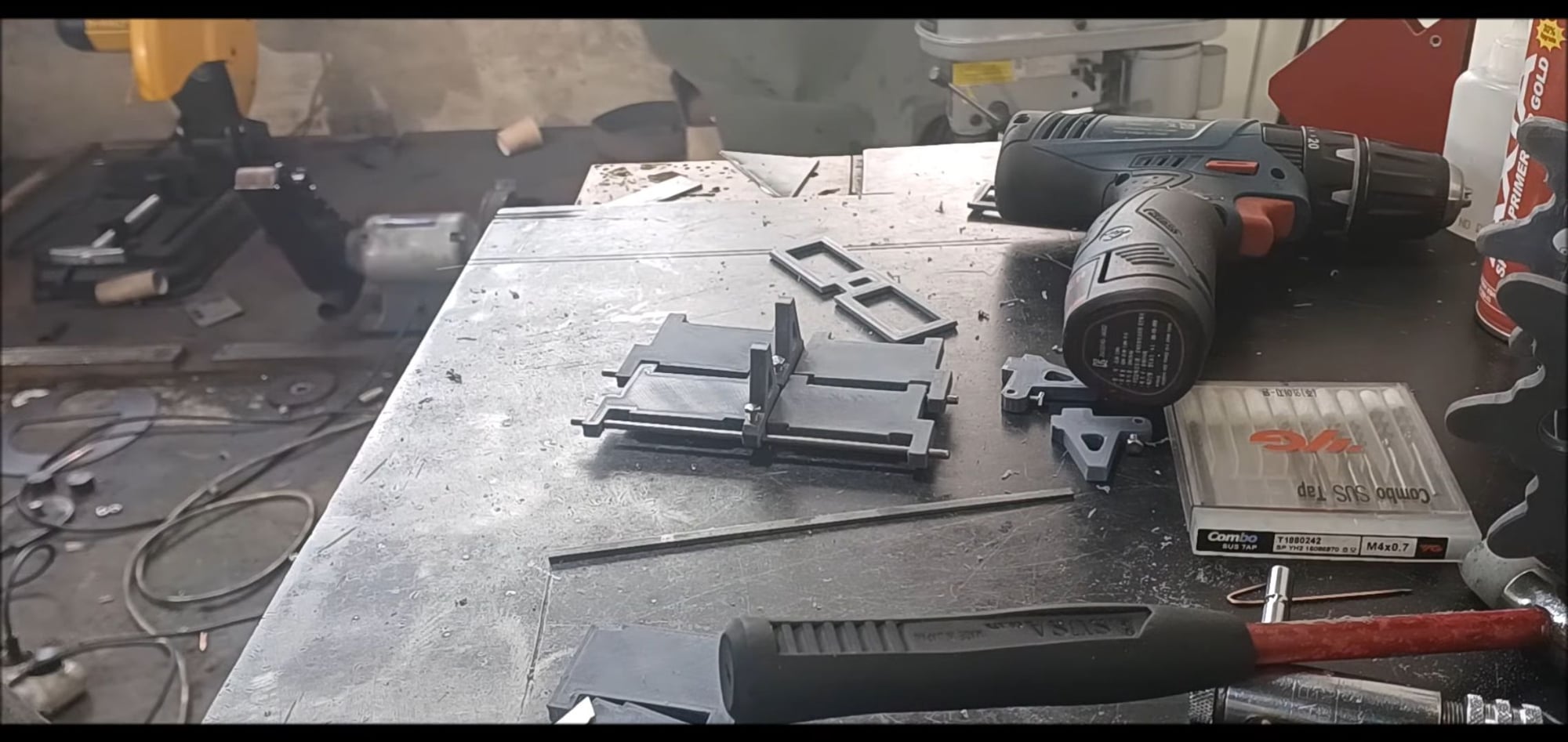

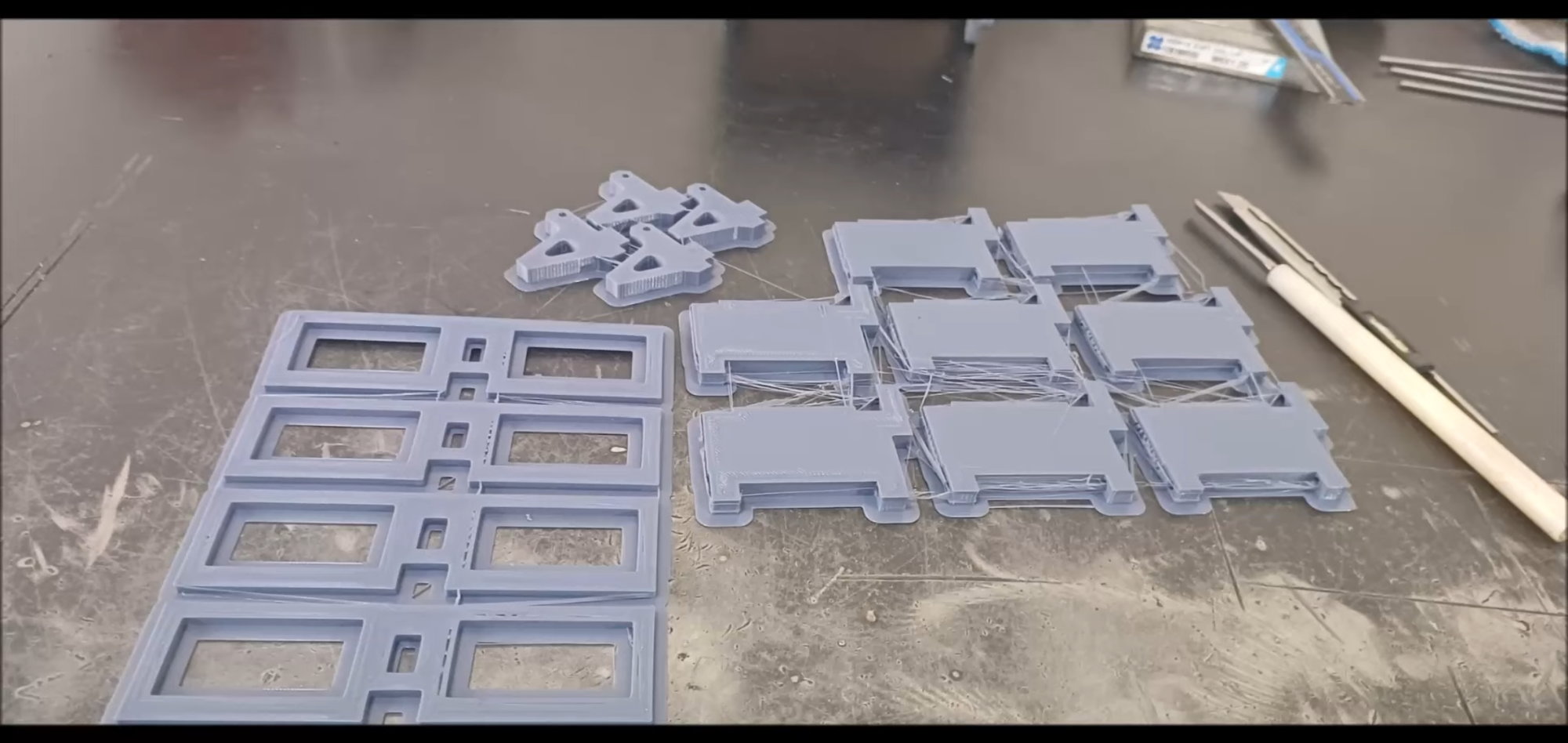

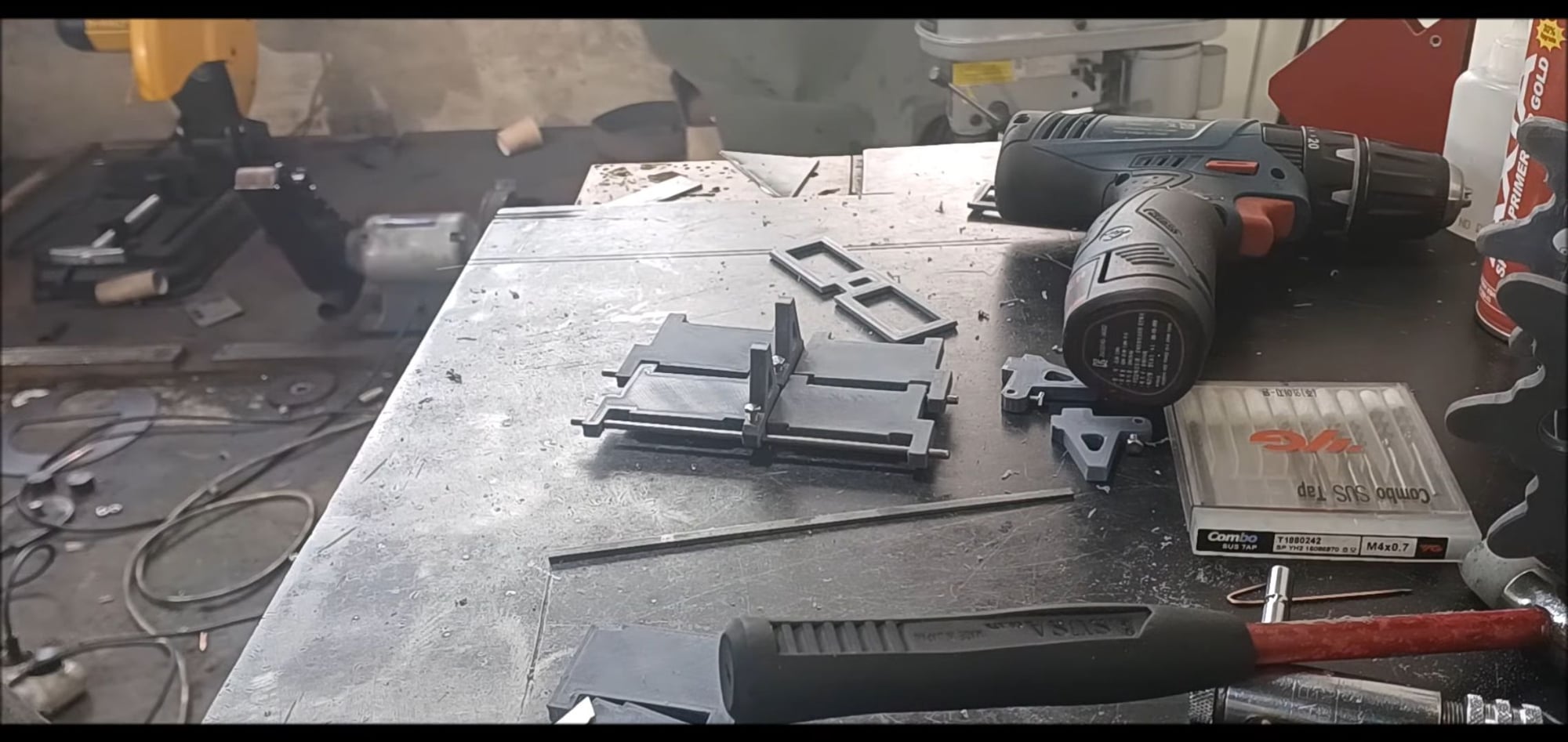

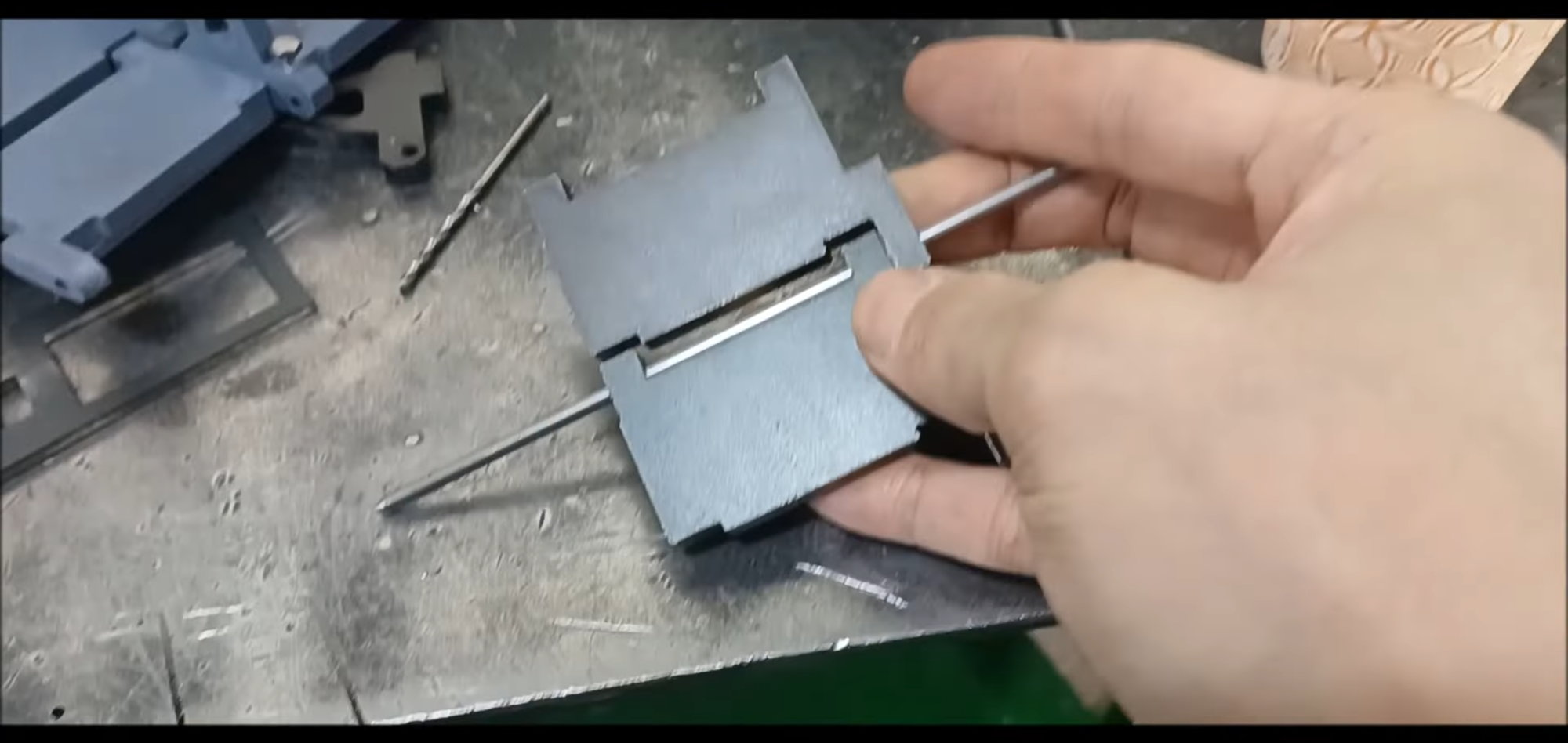

Samples are produced with 3D printers to verify the validity of the design.

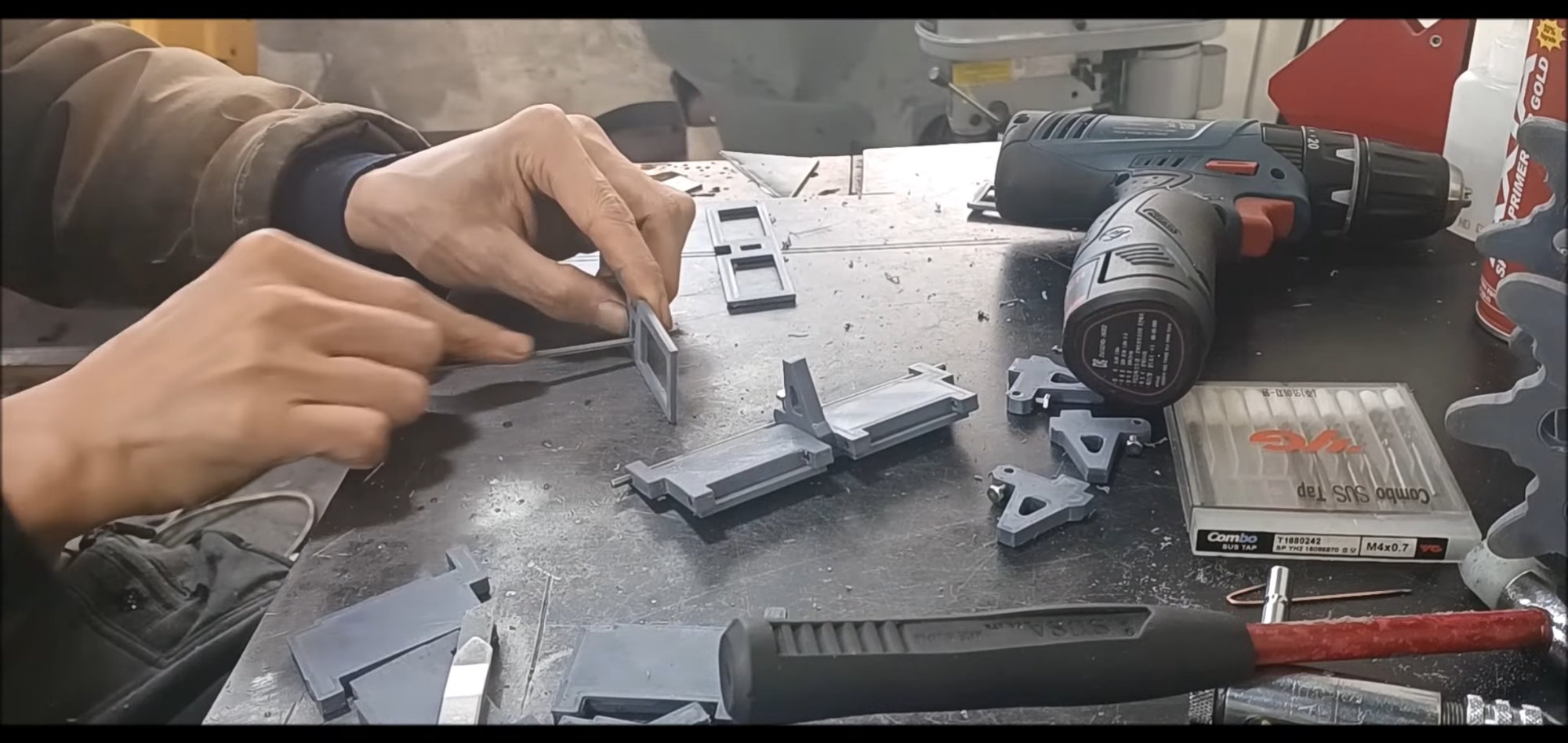

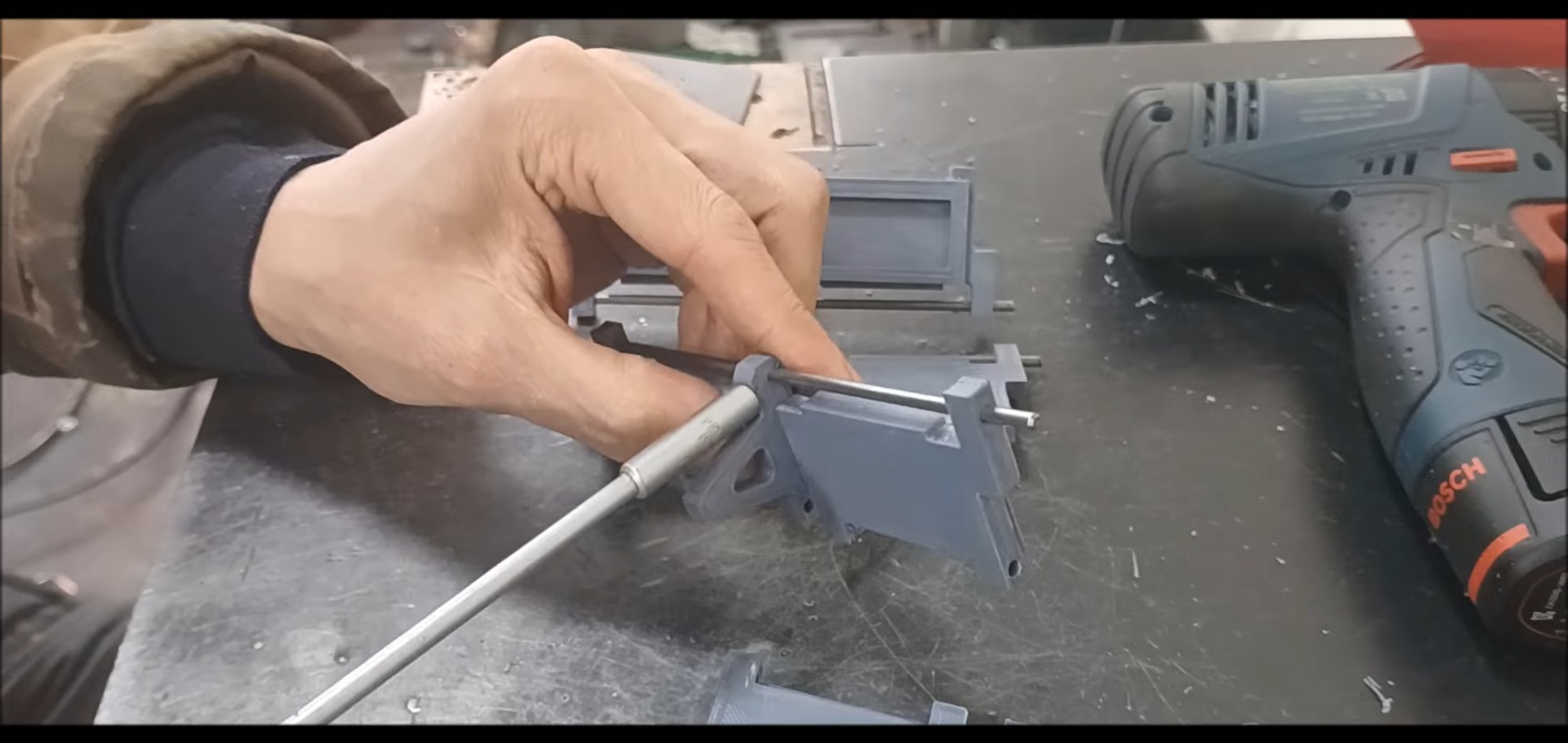

Clean up the output and perform screw tap work on the hole and the pin fixing.

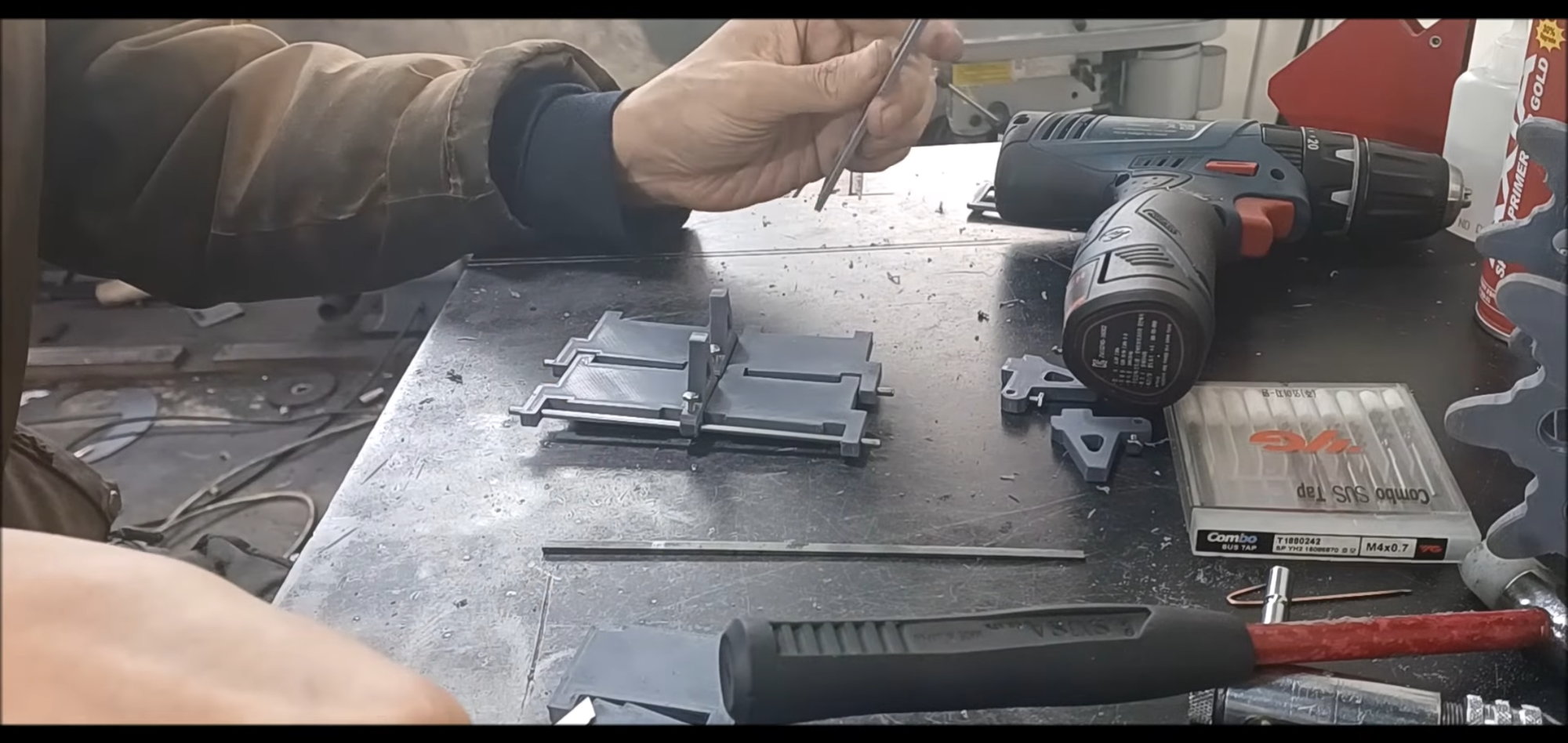

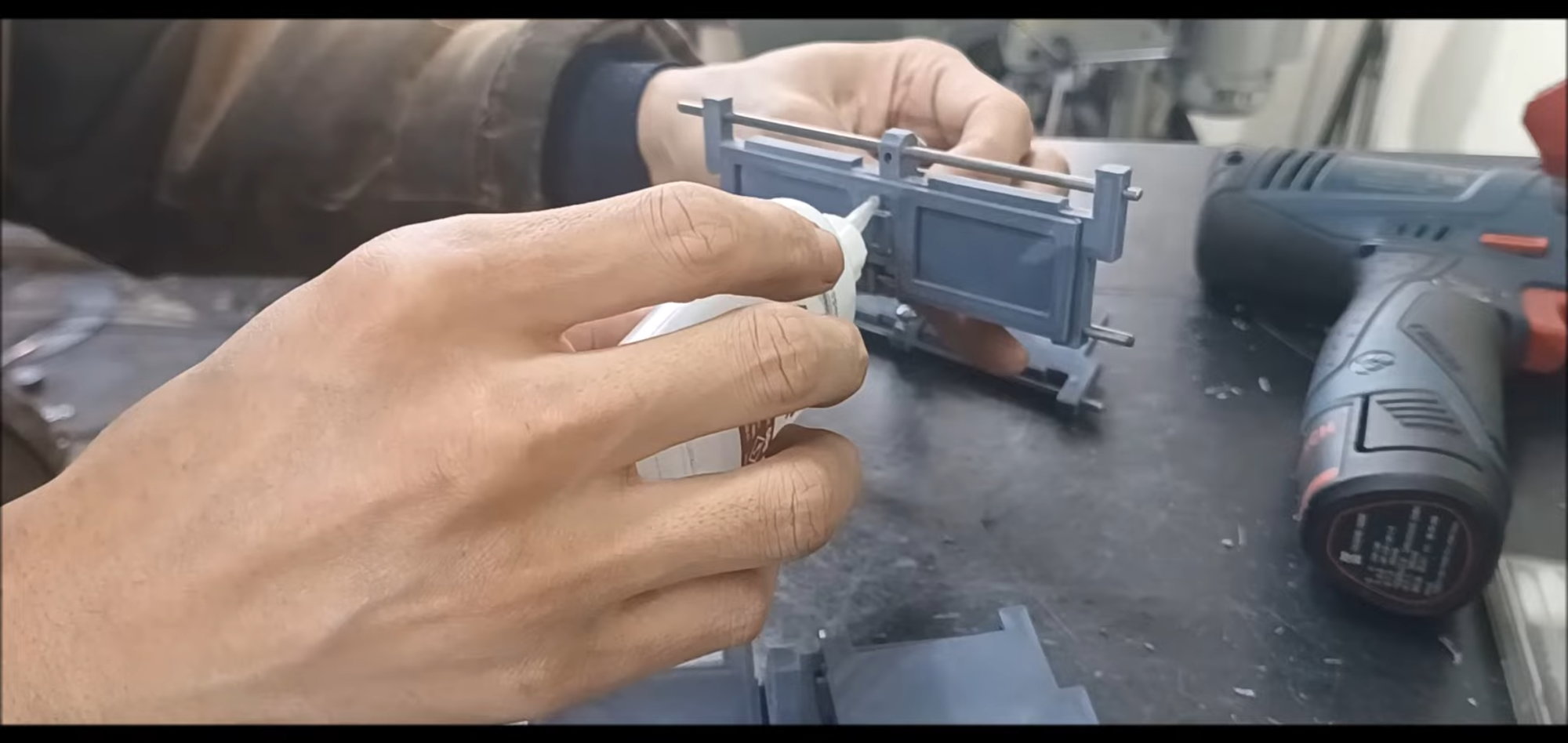

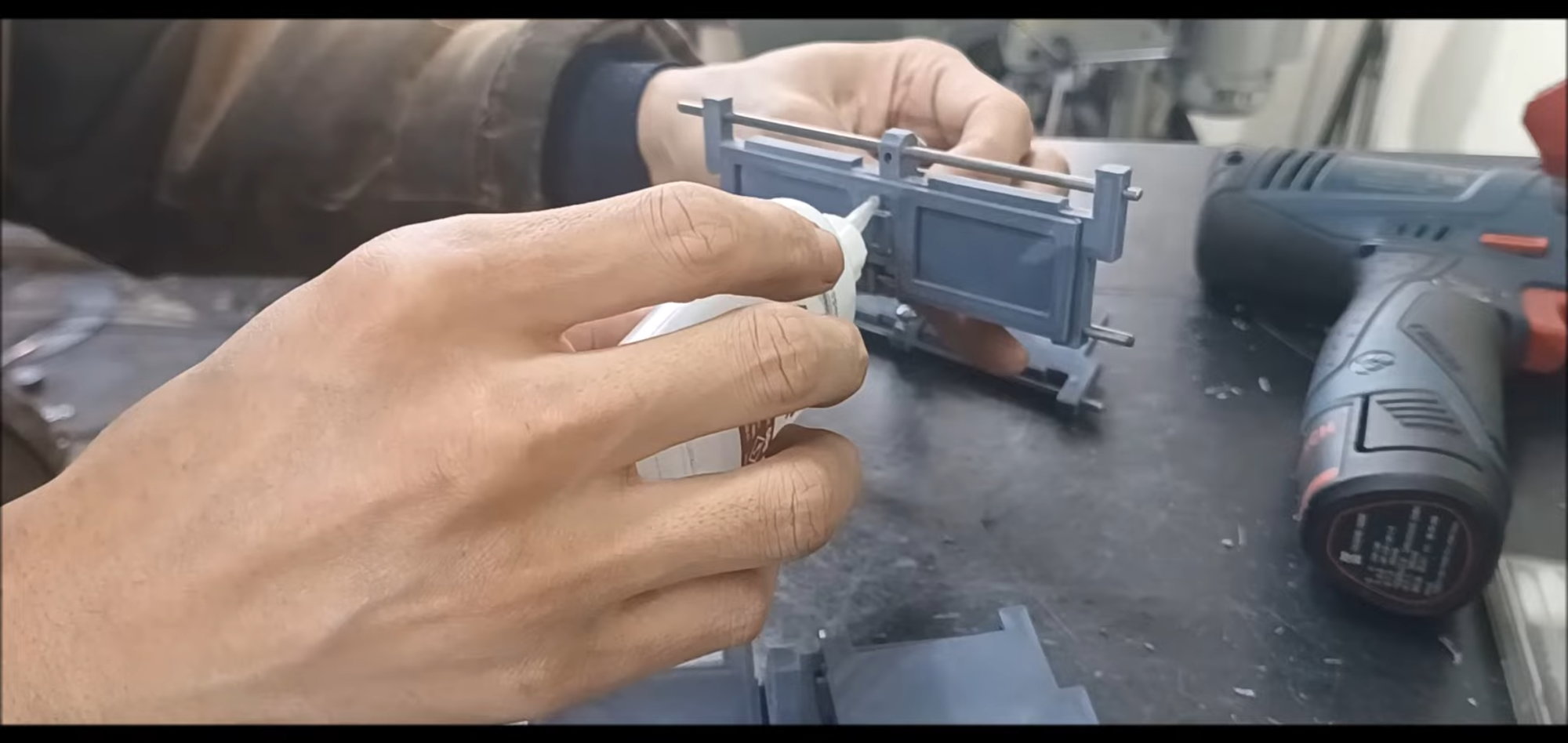

Check the location of the teg welding with adhesive.

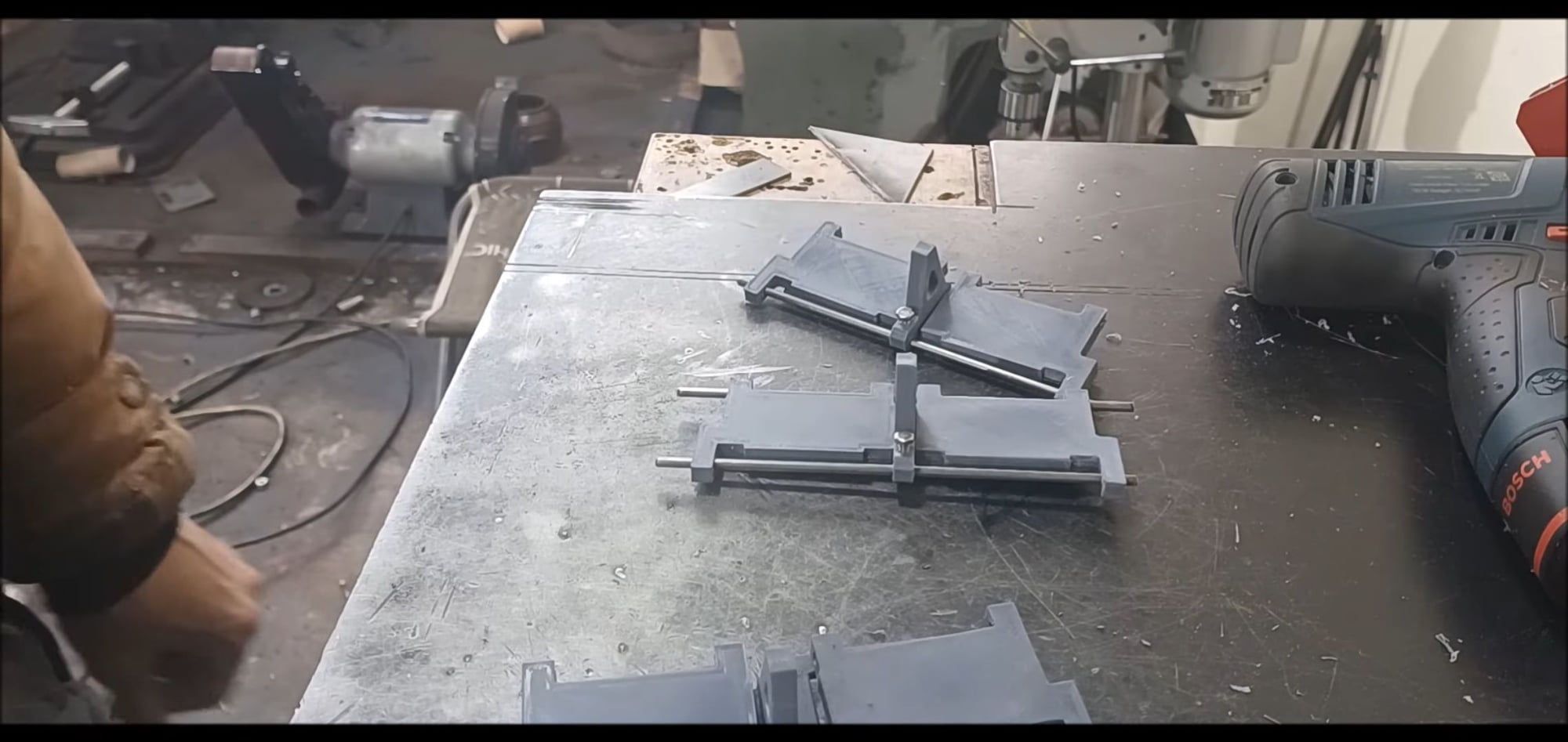

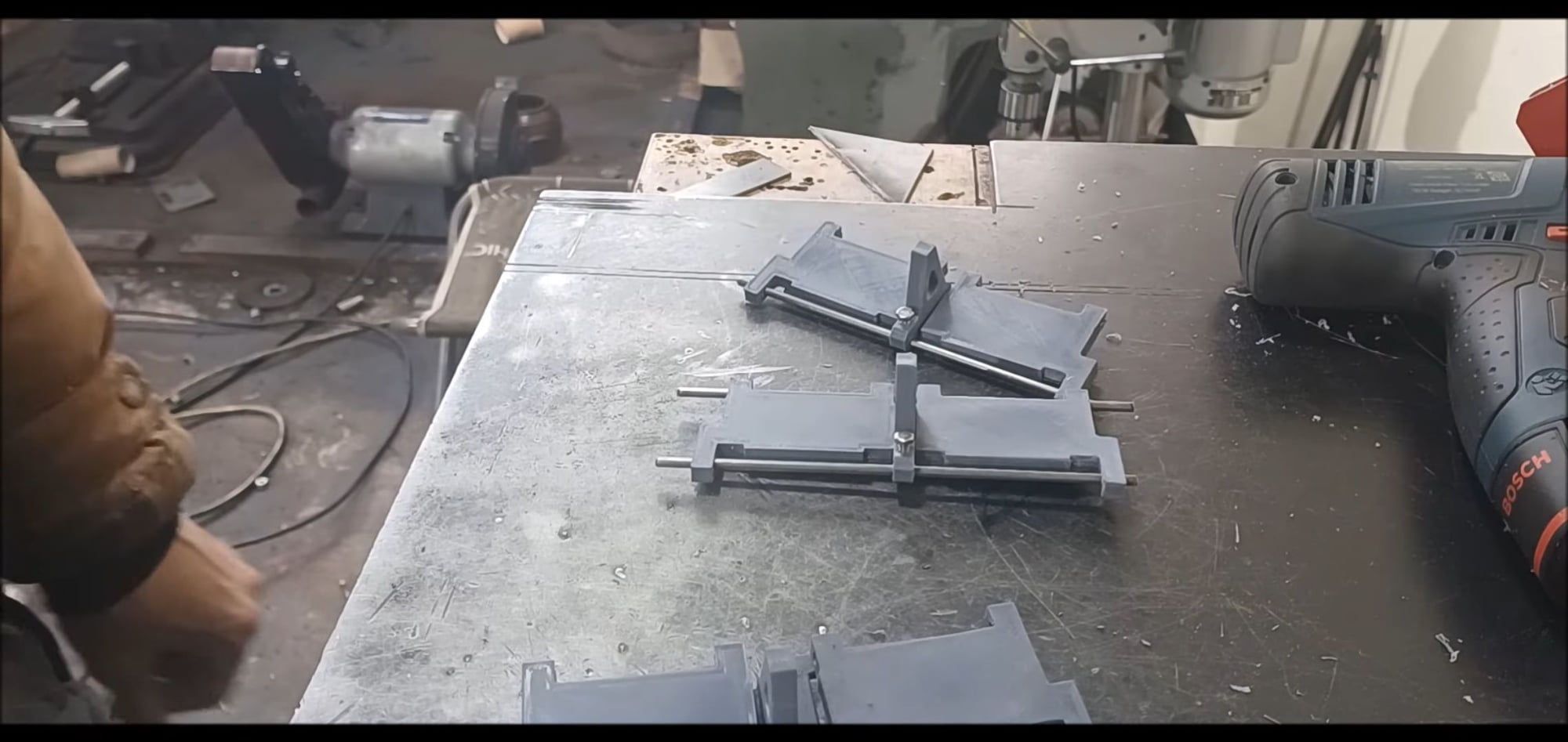

Put 4 sets together on a trial basis.

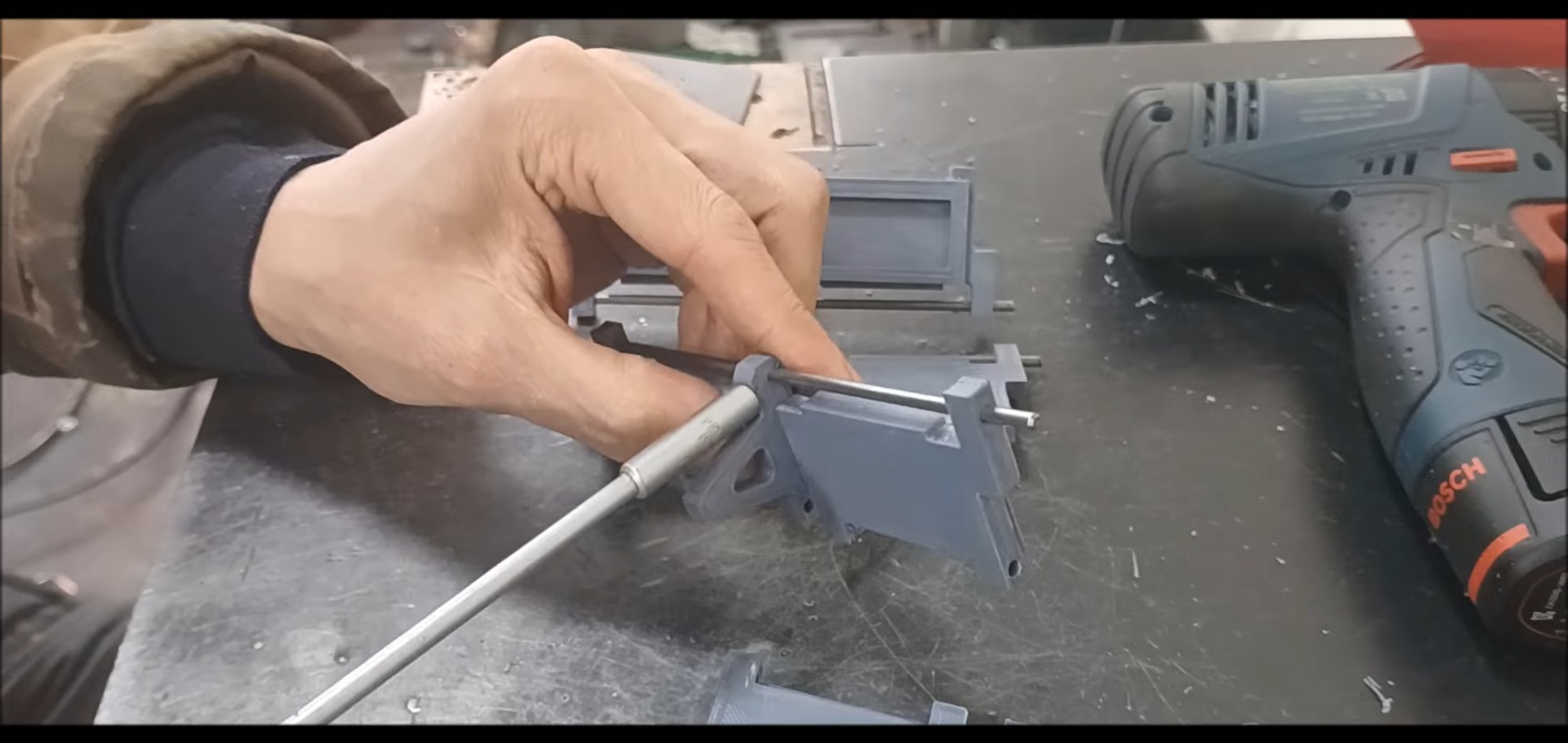

Round work is done on the part that is in contact with the sprocket.

Roll the sample into a sprocket and review its validity.

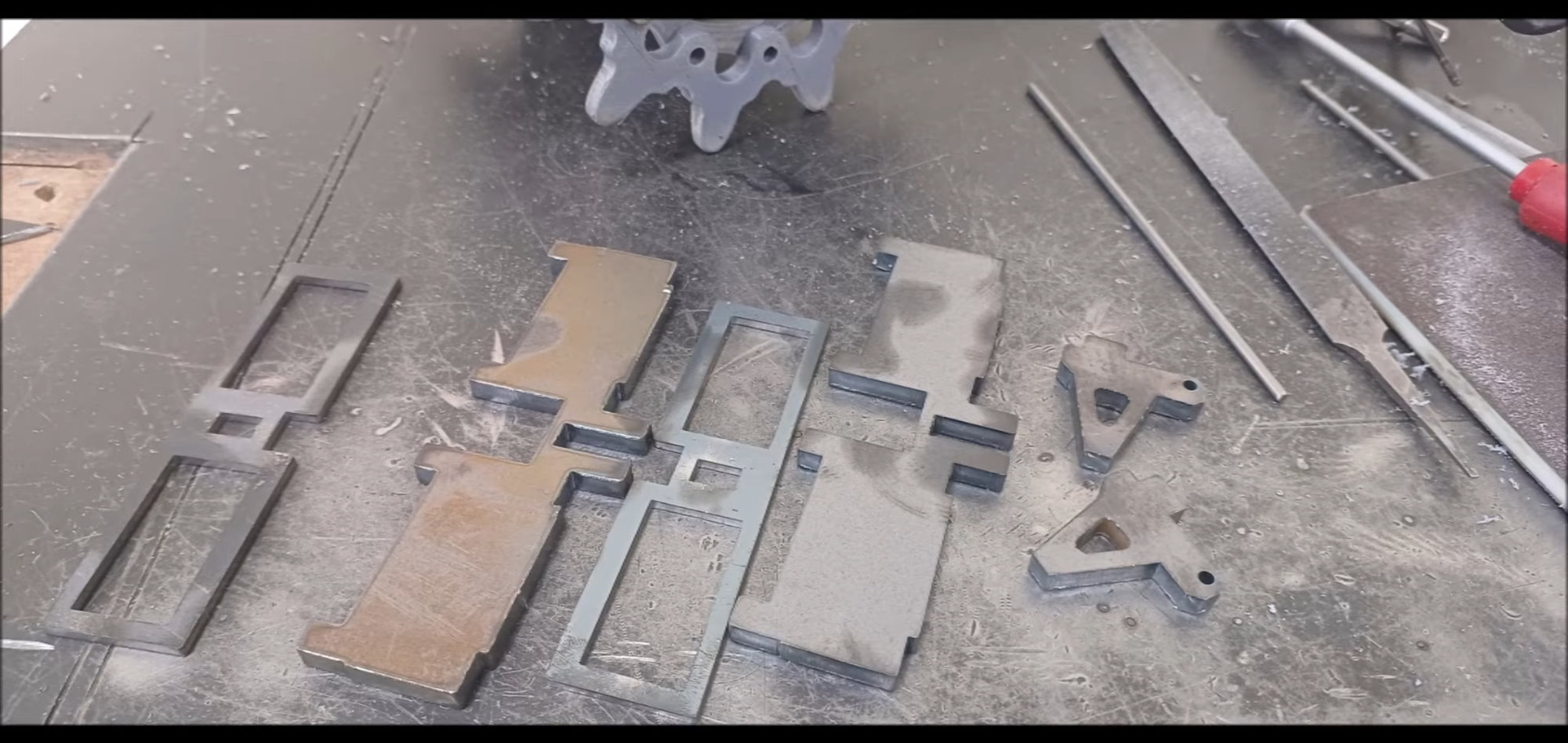

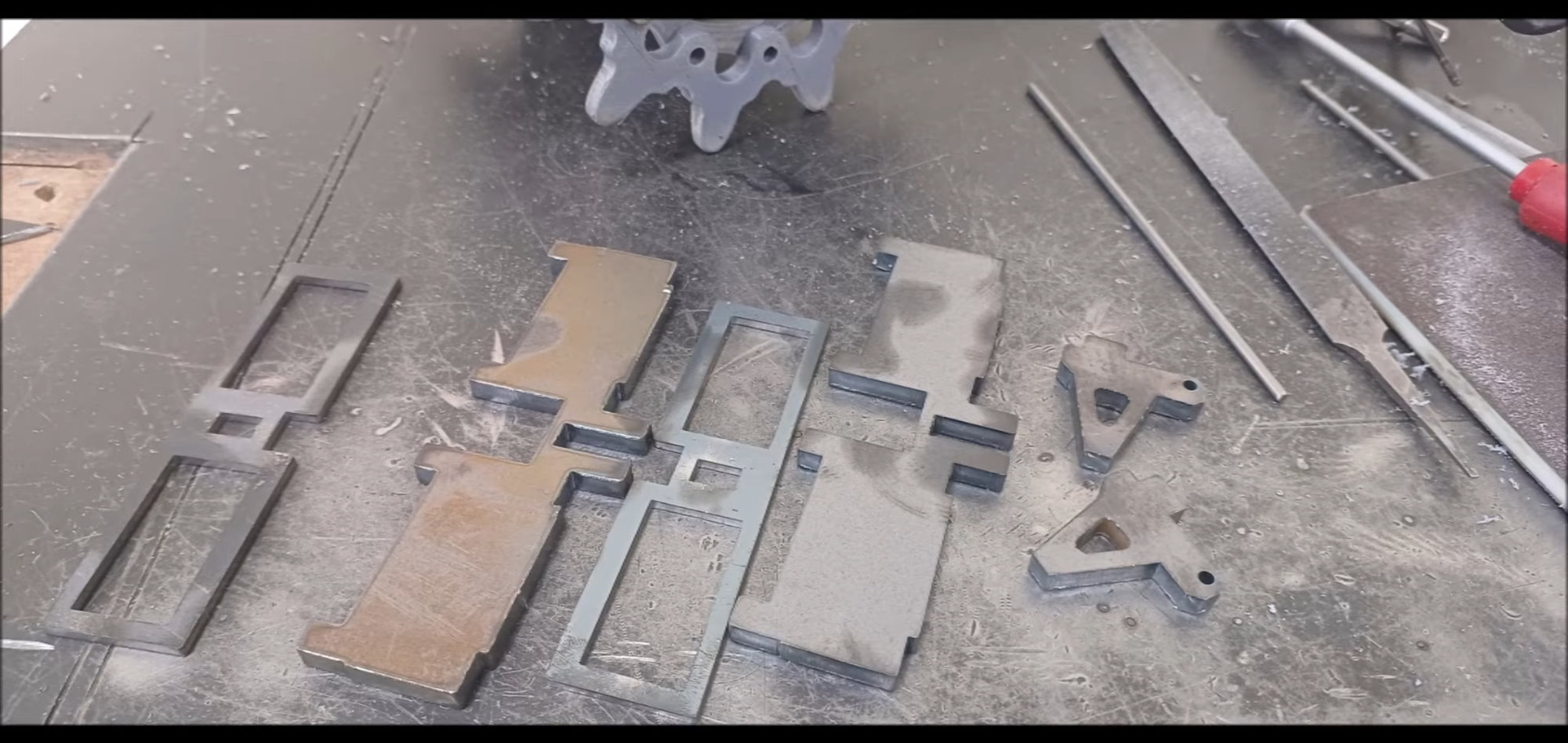

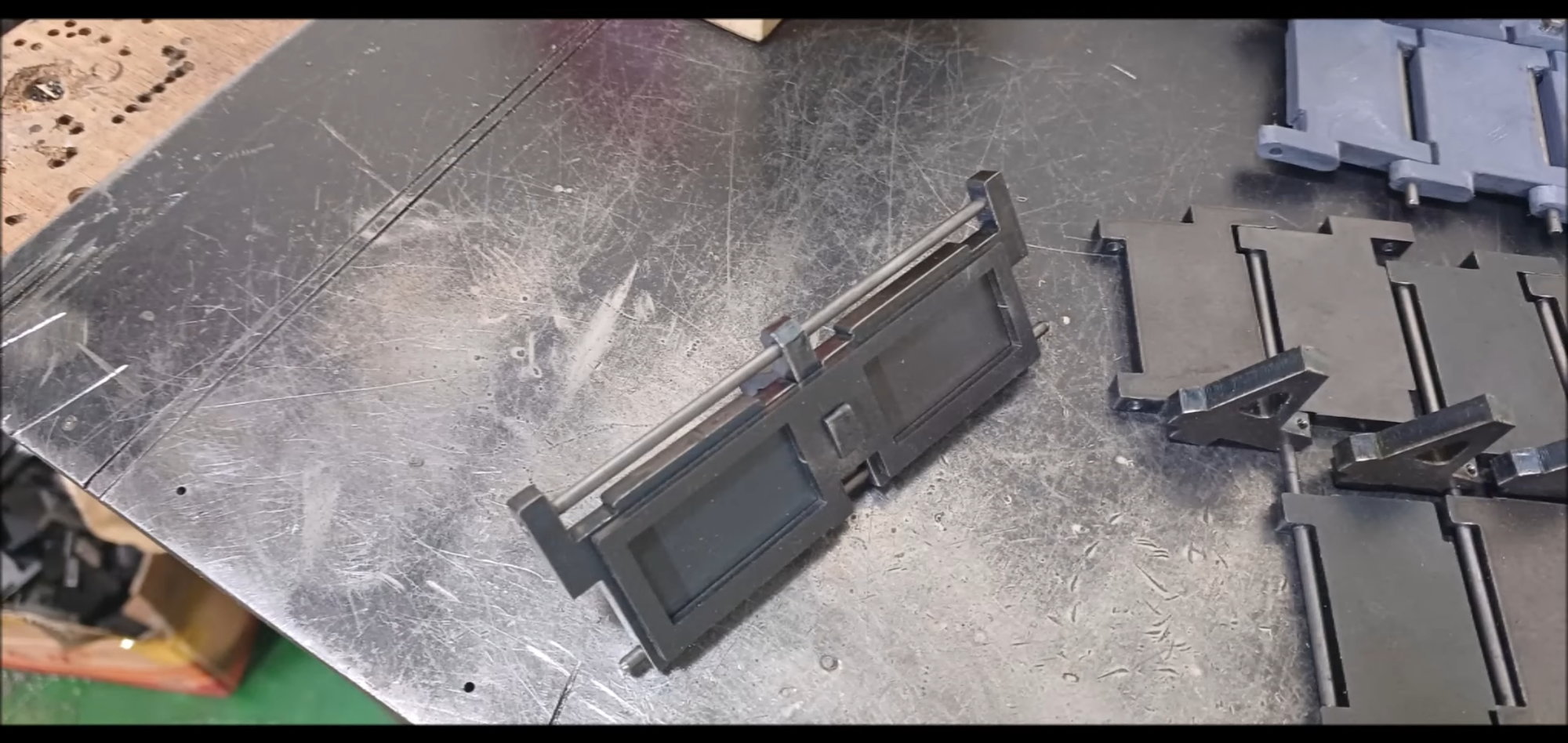

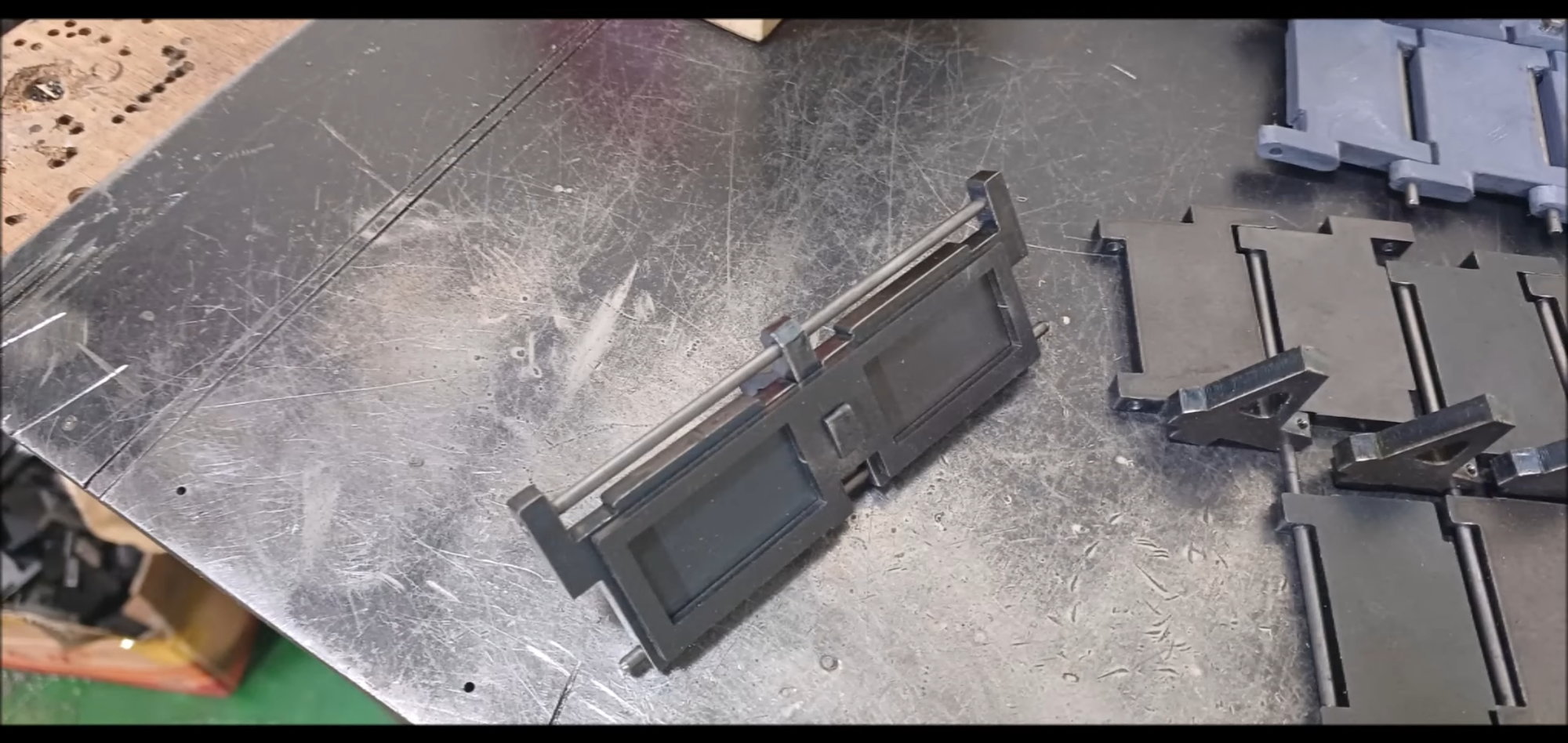

Laser processing of steel materials according to the design.

parts to be a pair of caterpillar

The center guide, which is a laser workpiece, must remove the burr and work on a 3mm screw tape.

Use a hand grinder to remove burrs from all 160 center guides.

Hold the drill reference point for the screw tape.

Drill 160 center guides.

Center guide after deburring and taping

The work that is the basis for the fabrication of the model tank begins with a caterpillar.

The new model will be powered by a combination of a 35cc gasoline engine and a hydraulic motor, which will weigh more than the 2022 version.

Therefore, the caterpillar production method was produced by converting from a method that emphasizes detail to a method that is durable and easy to repair.

The structure of the caterpillar consists of a shoe body, a rubber pad guide, a center guide, and a connecting pin, and a rubber pad will be attached to the lower part.

Please refer to the following YouTube video for the production process, and the photo below is captured from the YouTube video.

Samples are produced with 3D printers to verify the validity of the design.

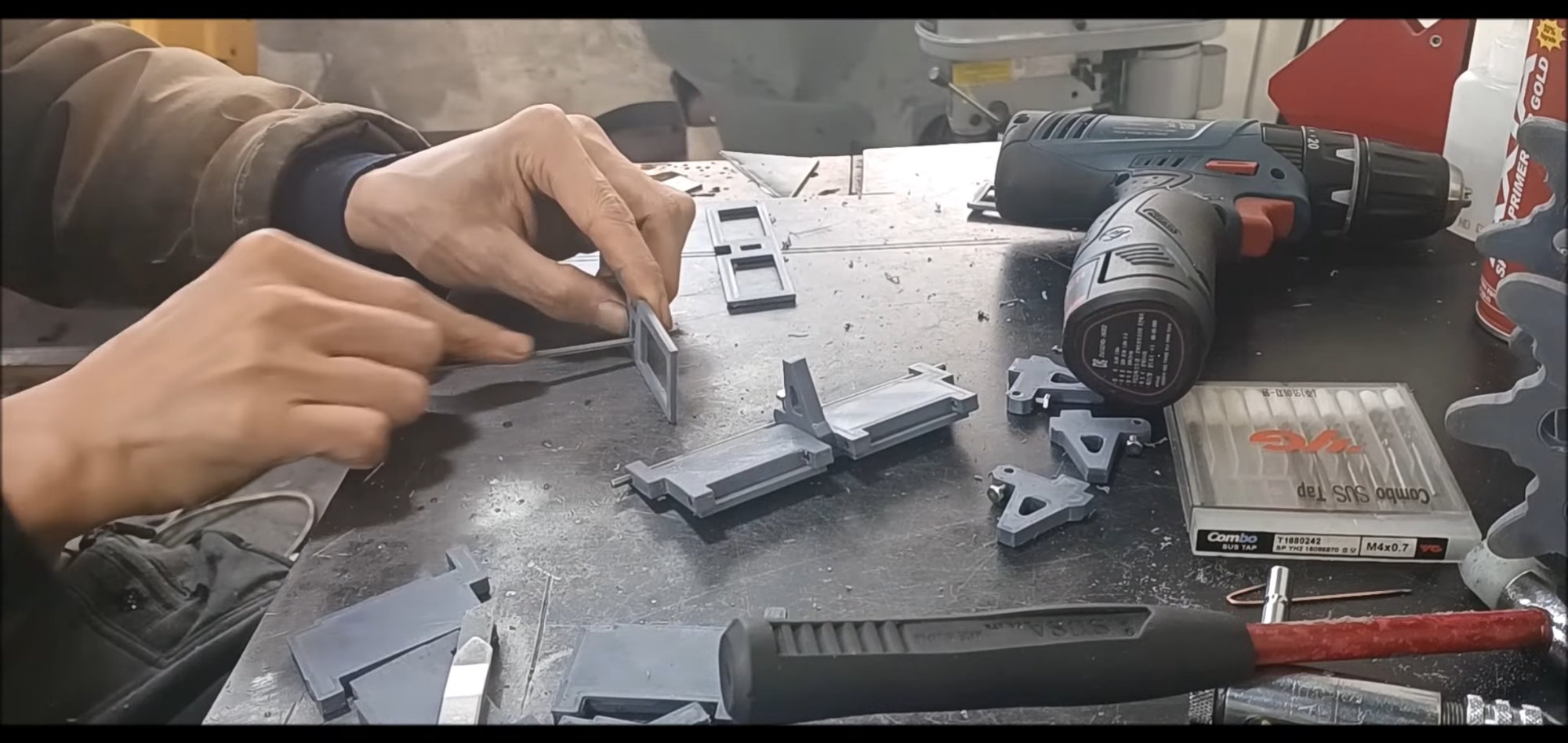

Clean up the output and perform screw tap work on the hole and the pin fixing.

Check the location of the teg welding with adhesive.

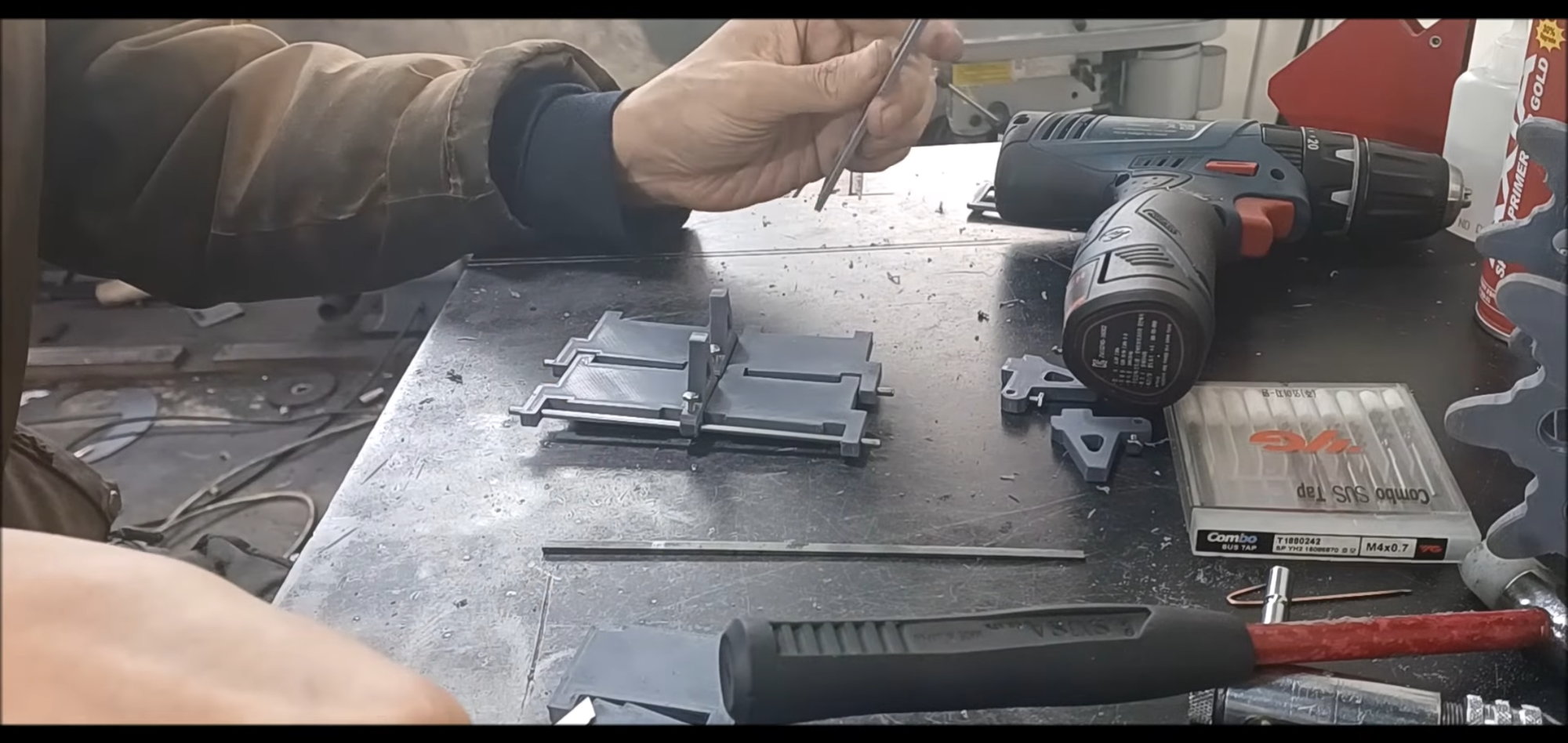

Put 4 sets together on a trial basis.

Round work is done on the part that is in contact with the sprocket.

Roll the sample into a sprocket and review its validity.

Laser processing of steel materials according to the design.

parts to be a pair of caterpillar

The center guide, which is a laser workpiece, must remove the burr and work on a 3mm screw tape.

Use a hand grinder to remove burrs from all 160 center guides.

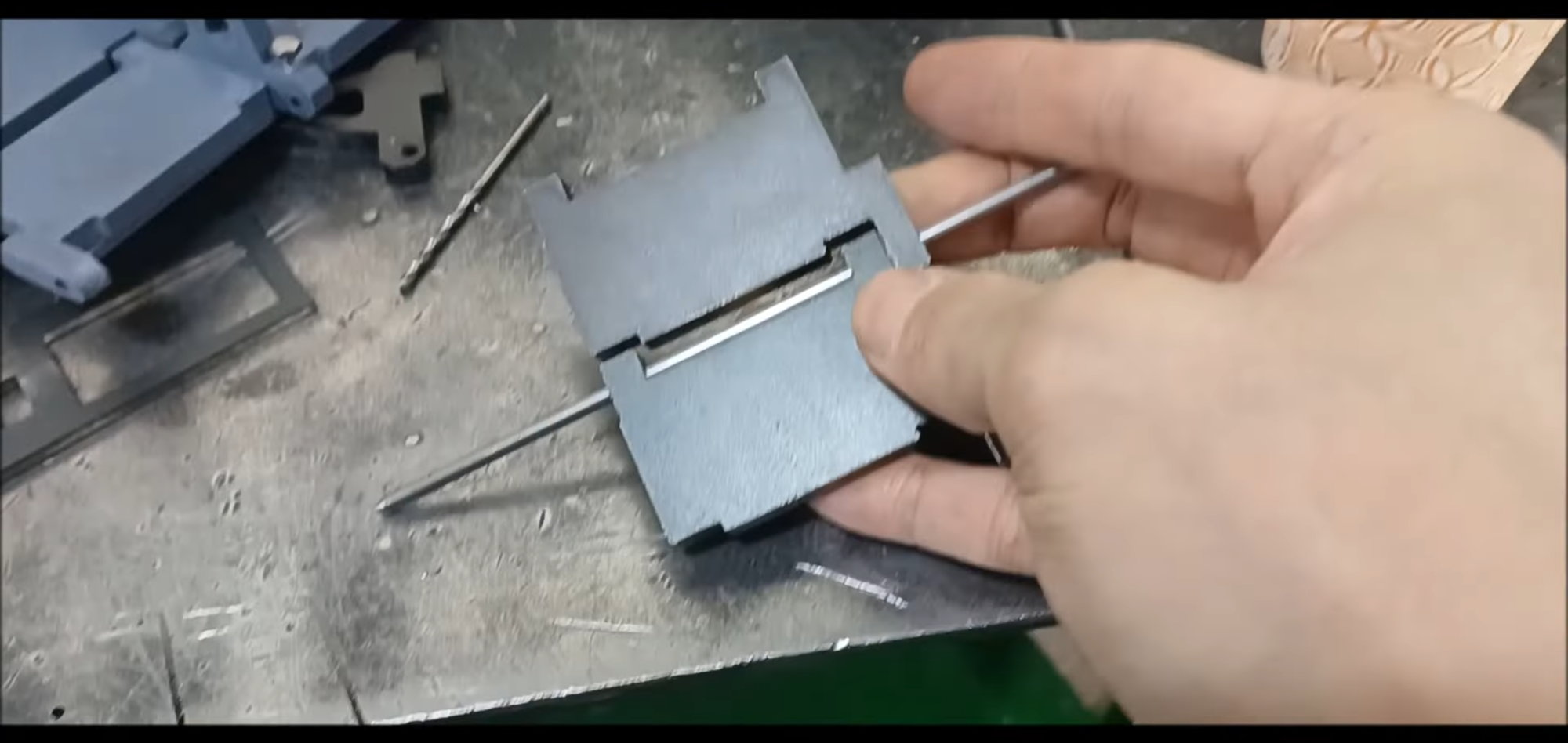

Hold the drill reference point for the screw tape.

Drill 160 center guides.

Center guide after deburring and taping

Last edited by PE YOUNG; 03-03-2023 at 07:44 AM.

The following users liked this post:

tankme (03-03-2023)

#7

Thread Starter

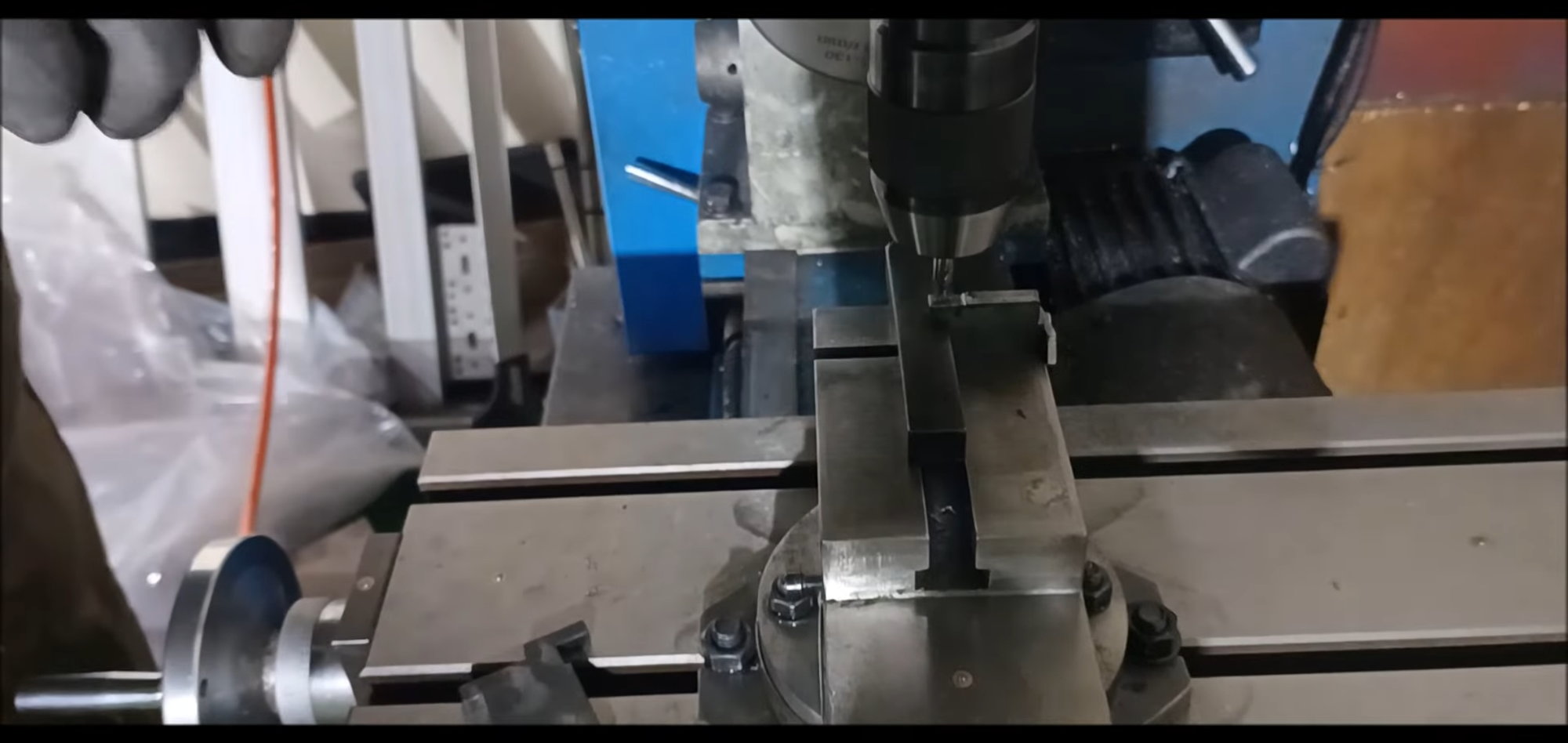

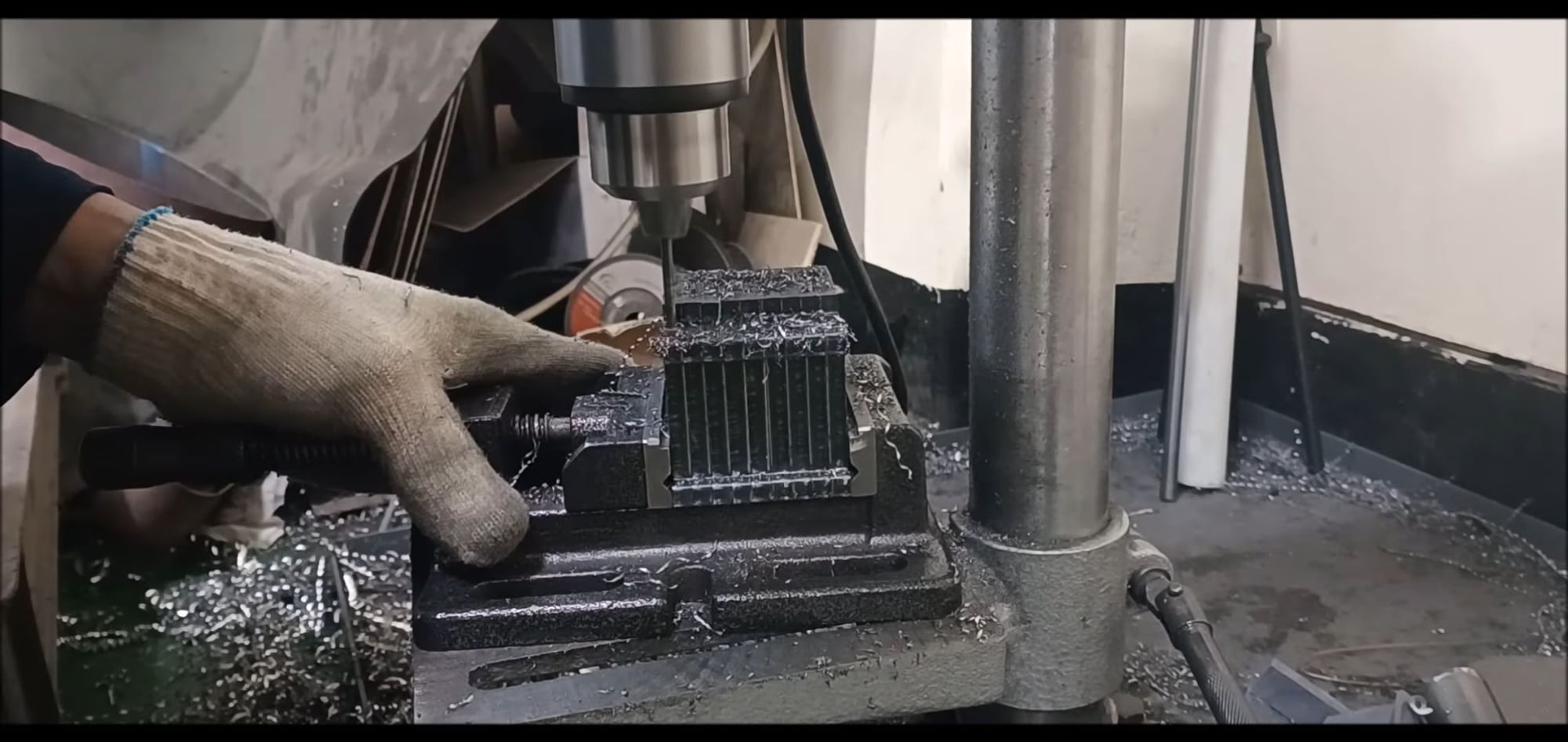

Drill work and screw-tape work on the center guide and body among the components of the caterpillar.

Considering the workability, the casting process is convenient, but it is a process of assembling one by one considering the economic feasibility.

Please refer to the YouTube address below for the video.

Prepare parts for the next lower steel structure in advance

160 center guides for screw-tape work

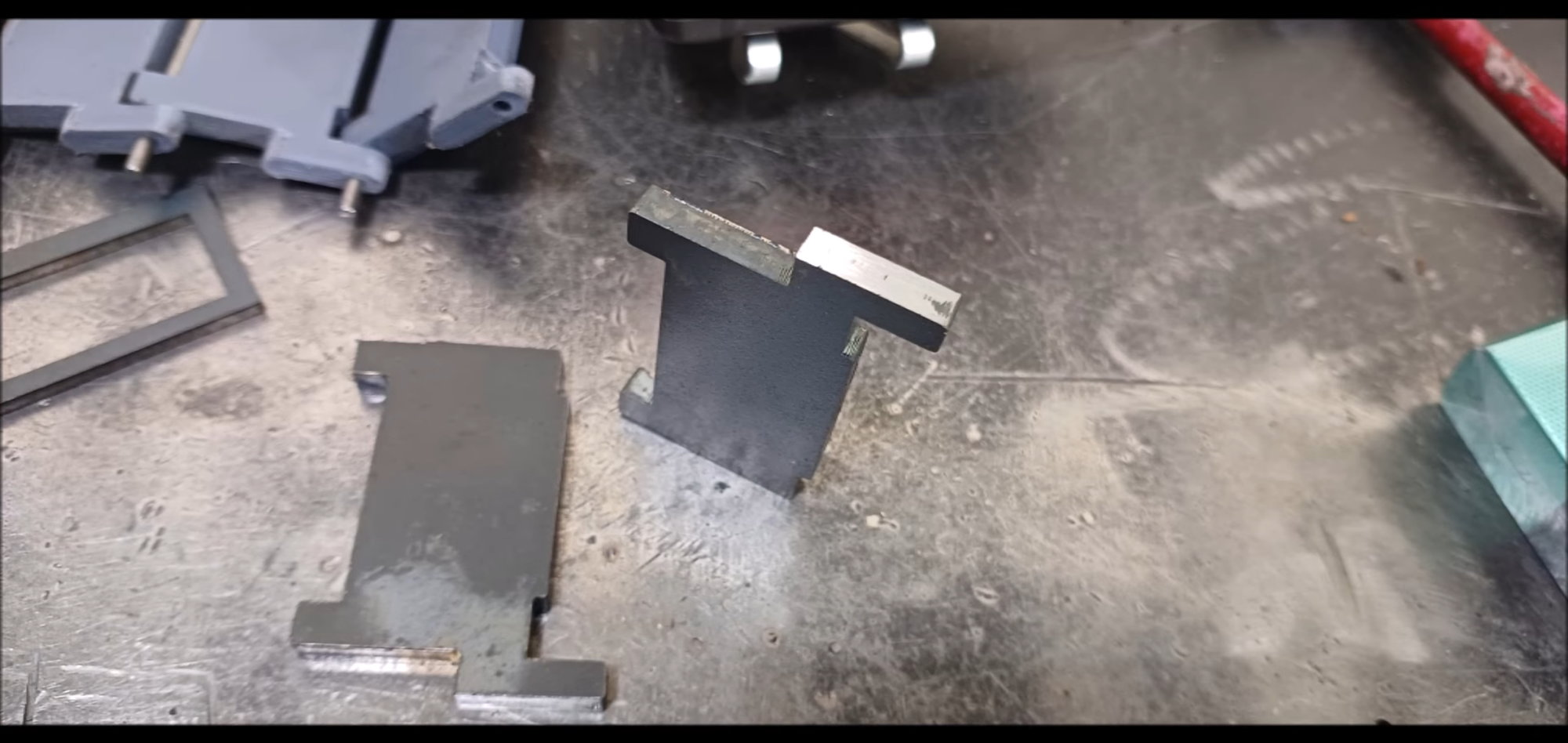

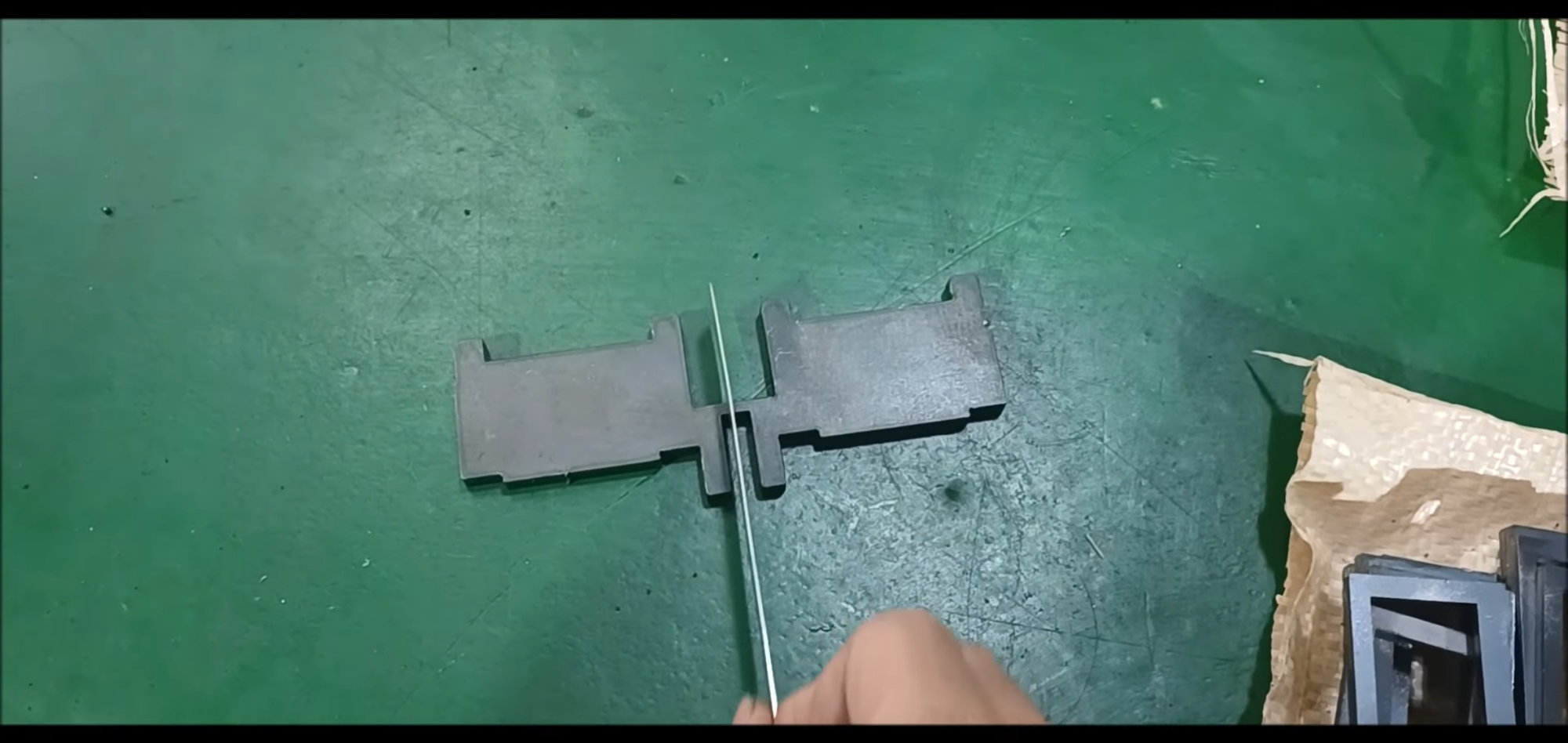

a completed sample

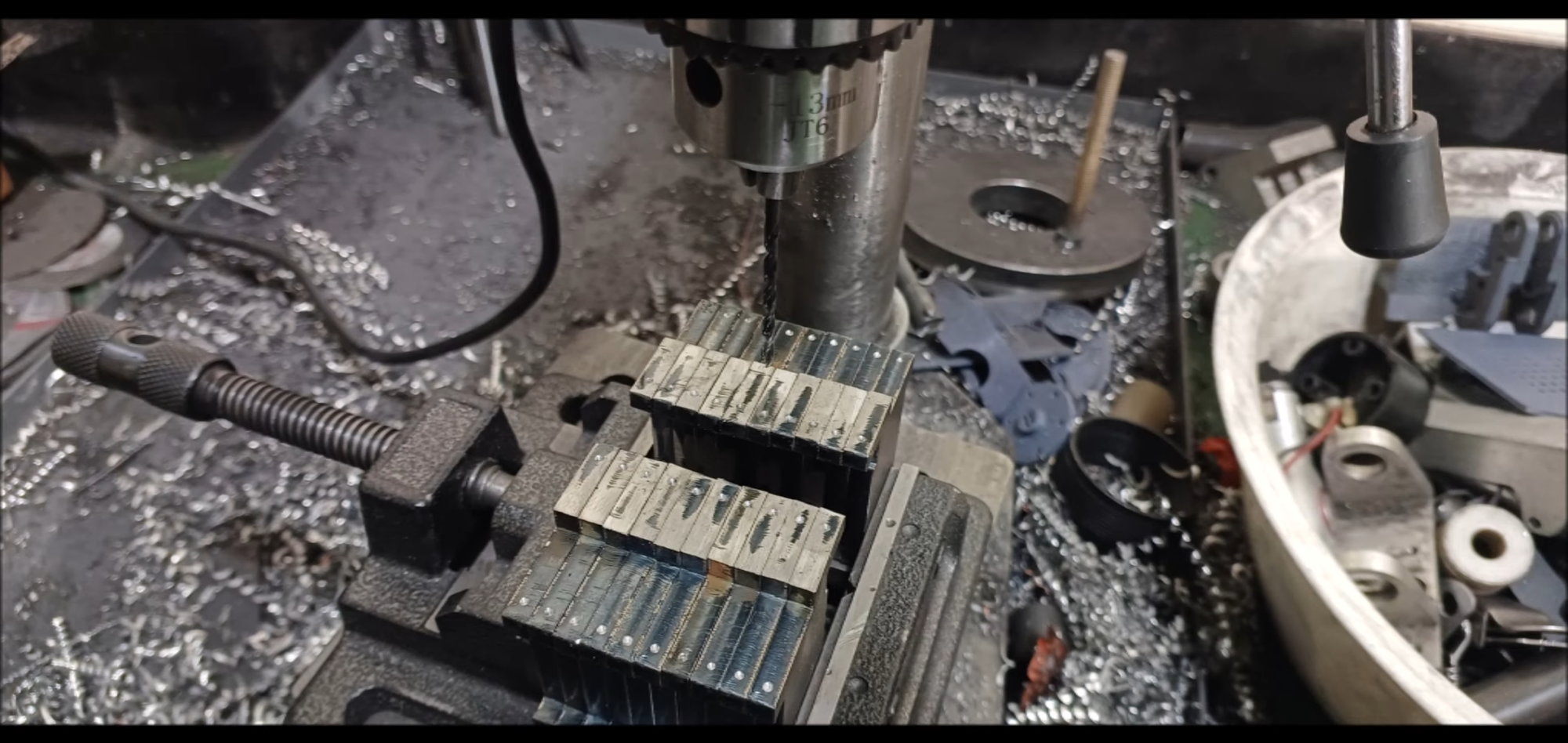

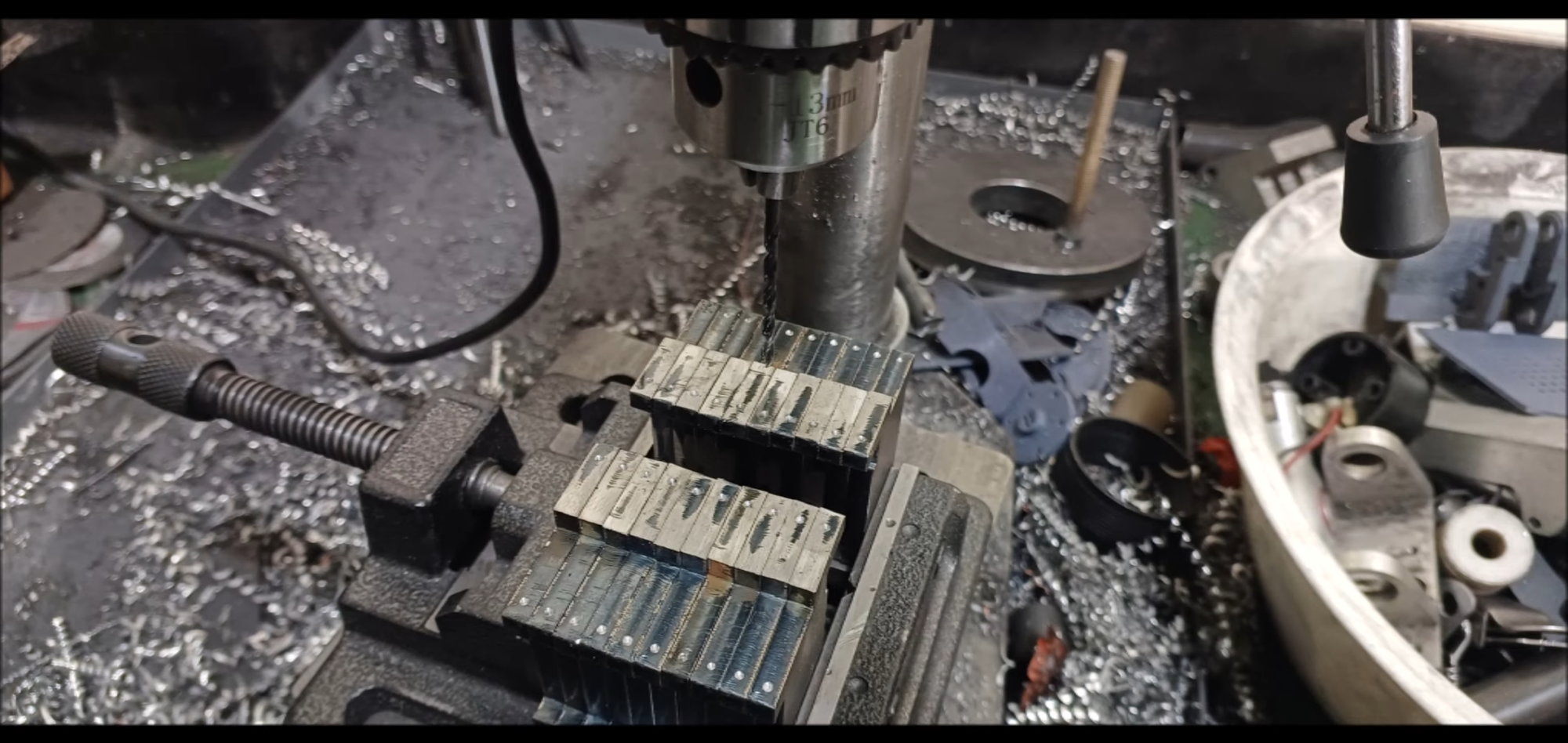

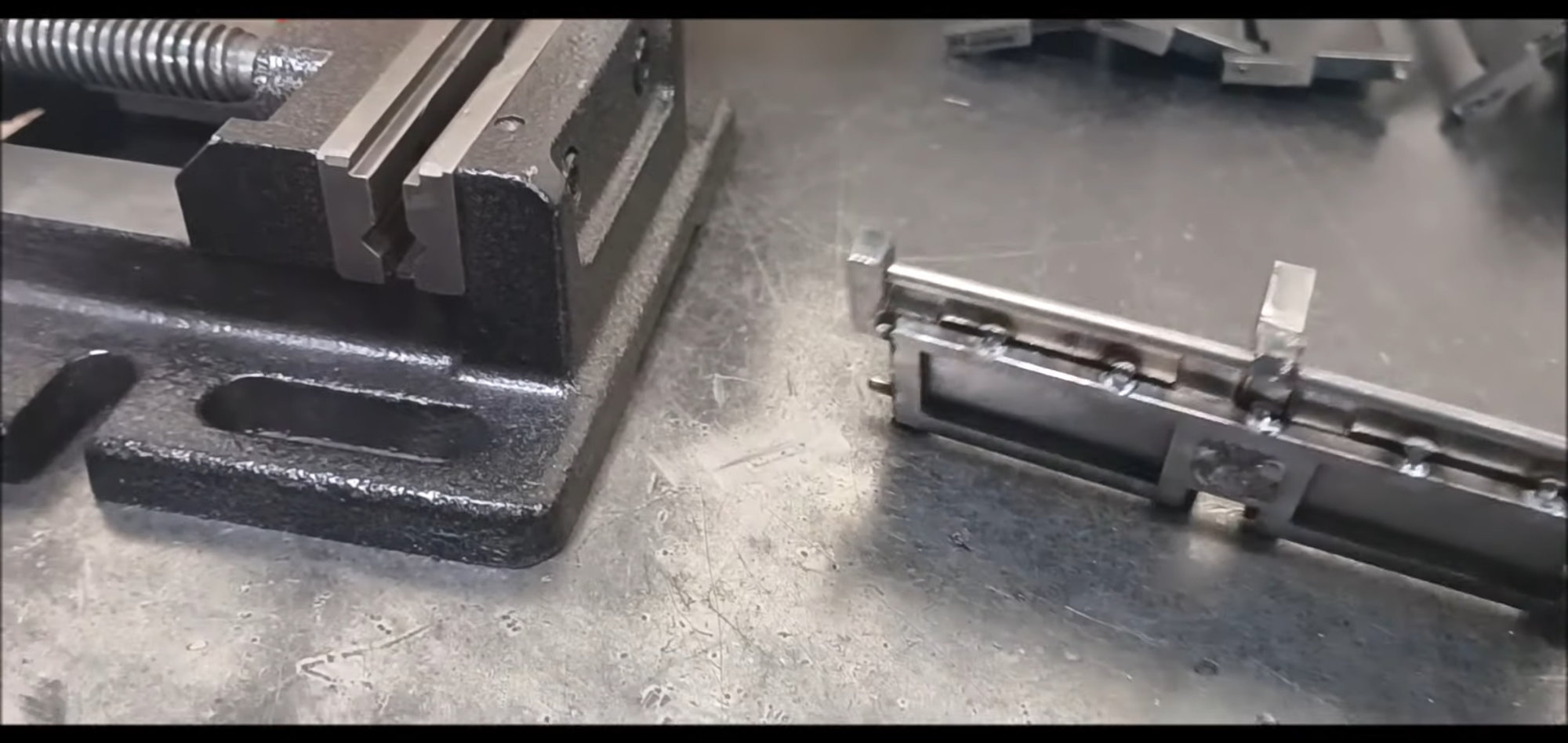

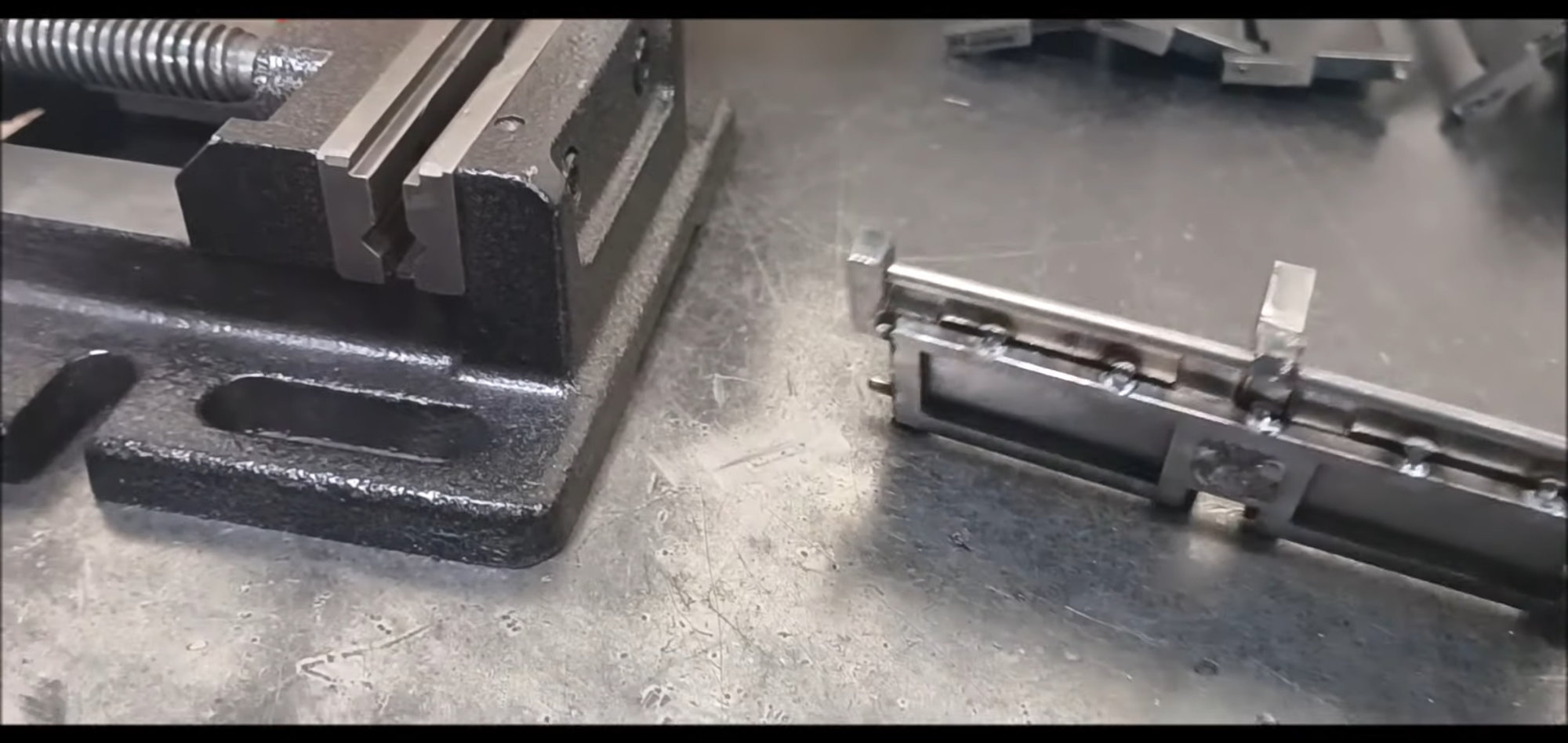

Multiple center guides are tied to a table vice and drill and screw tape are performed simultaneously.

Considering the burrs and costs incurred during laser operation, the caterpillar body is made in one body.

160 Caterpillar Parts

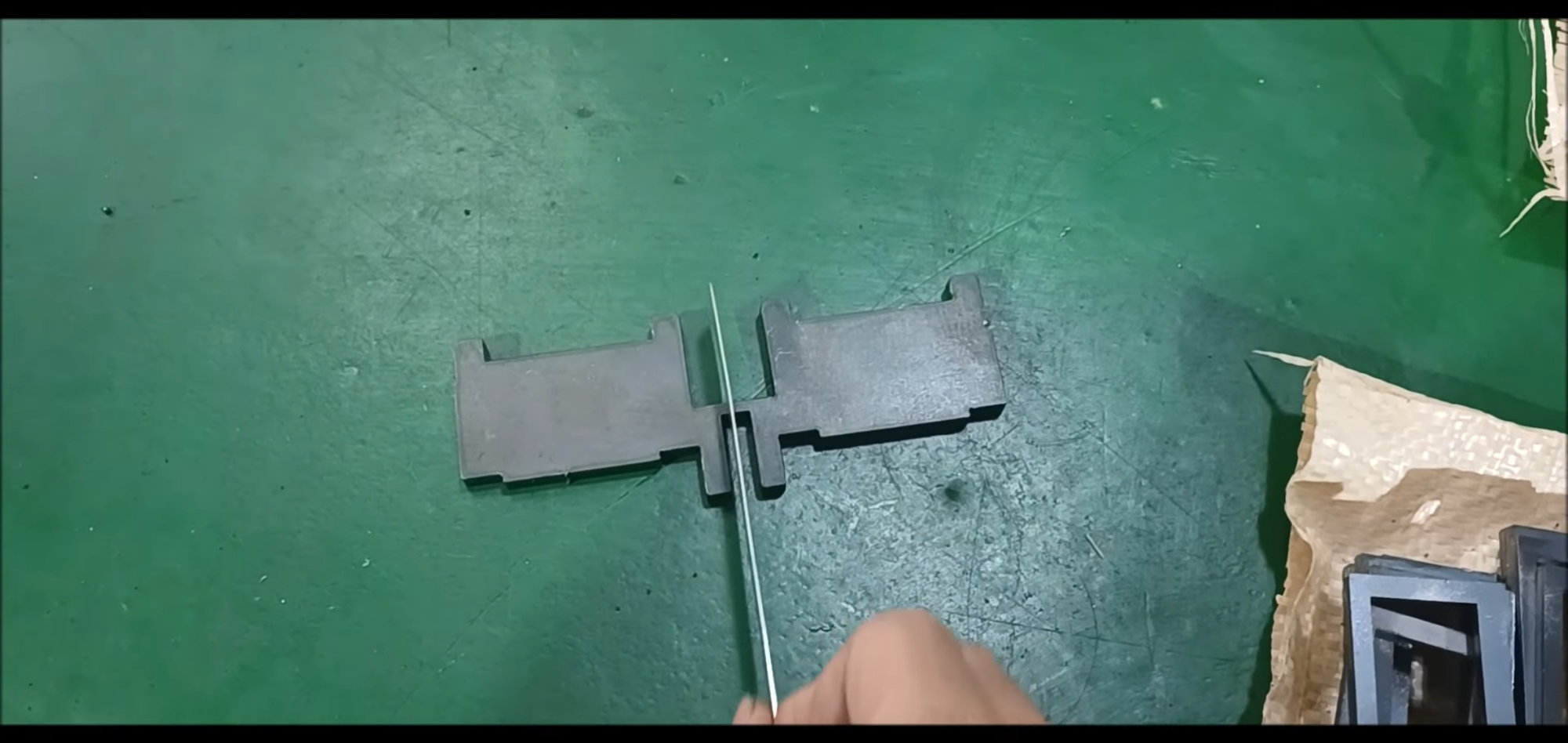

Divide the caterpillar body into two pieces with a cutting machine.

Parts to work increased to 320

Burr Occurred During Laser operation

Burr generated during cutting operation

Burr removal operation

a completed sample

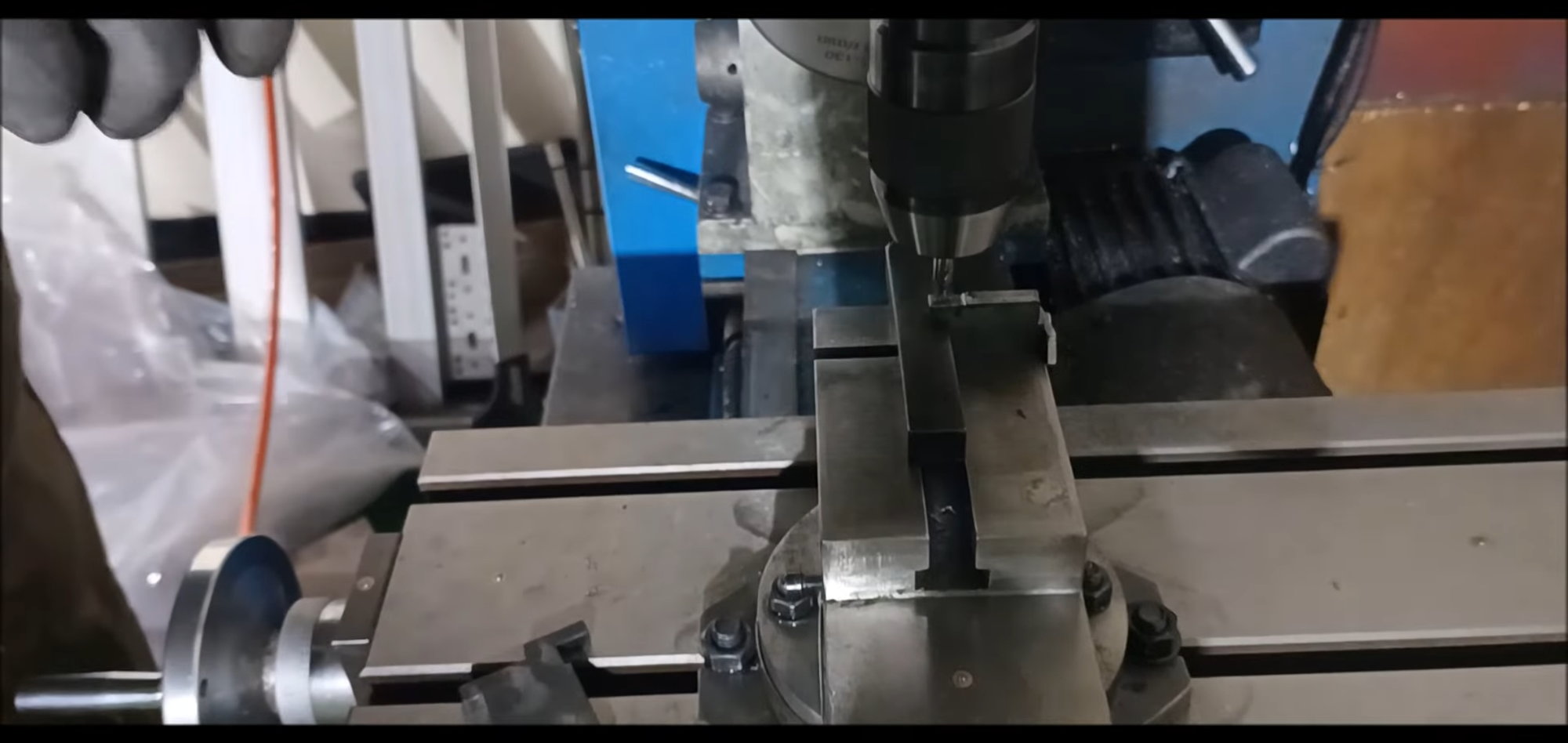

Pre-centering for drilling

Production Interim Verification

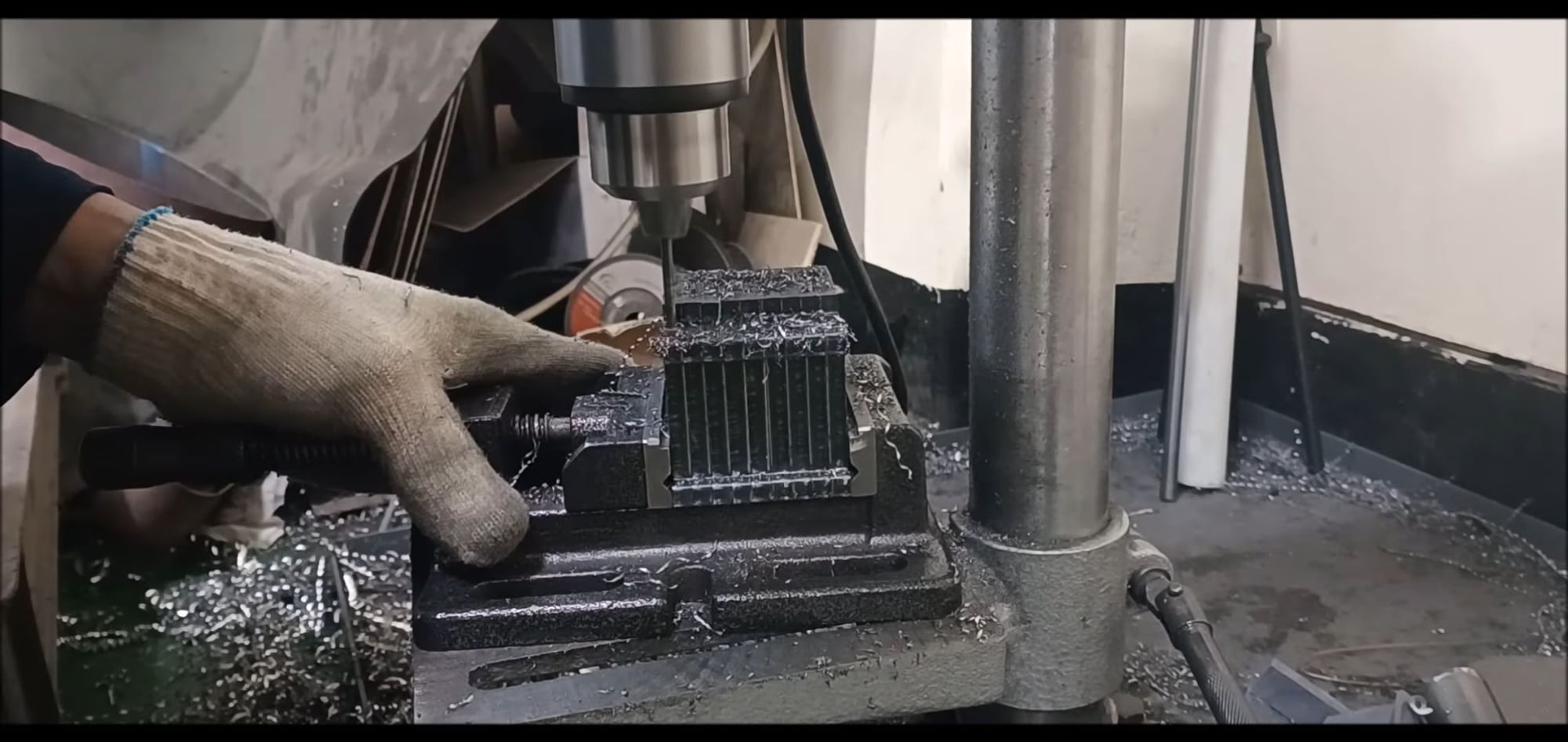

Full-scale hole work

It takes a lot of time to make 3 holes in one part.

See you next time.

Considering the workability, the casting process is convenient, but it is a process of assembling one by one considering the economic feasibility.

Please refer to the YouTube address below for the video.

Prepare parts for the next lower steel structure in advance

160 center guides for screw-tape work

a completed sample

Multiple center guides are tied to a table vice and drill and screw tape are performed simultaneously.

Considering the burrs and costs incurred during laser operation, the caterpillar body is made in one body.

160 Caterpillar Parts

Divide the caterpillar body into two pieces with a cutting machine.

Parts to work increased to 320

Burr Occurred During Laser operation

Burr generated during cutting operation

Burr removal operation

a completed sample

Pre-centering for drilling

Production Interim Verification

Full-scale hole work

It takes a lot of time to make 3 holes in one part.

See you next time.

Last edited by PE YOUNG; 03-03-2023 at 04:58 PM.

#8

Thread Starter

After the drilling operation, the shape is gradually completed by assembling and welding the cutter filler.

Please refer to the following for the production video.

Smaller to make holes for fixing pins in the continuous caterpillar body

Caterpillar body parts with hole process completed

Pre-assembly for validation

3mm diameter piano steel wire to be used as a caterpillar fixing pin

To fit the length, a pin. If you want to see this work, please refer to the 2022 K2 production video.

Use a hand drill and belt grinder to remove burrs from the cut fixing pins.

Produced one set for validation

Complete a set by welding

Rubber pad fixing parts and center guide spot welding

Position Calibration

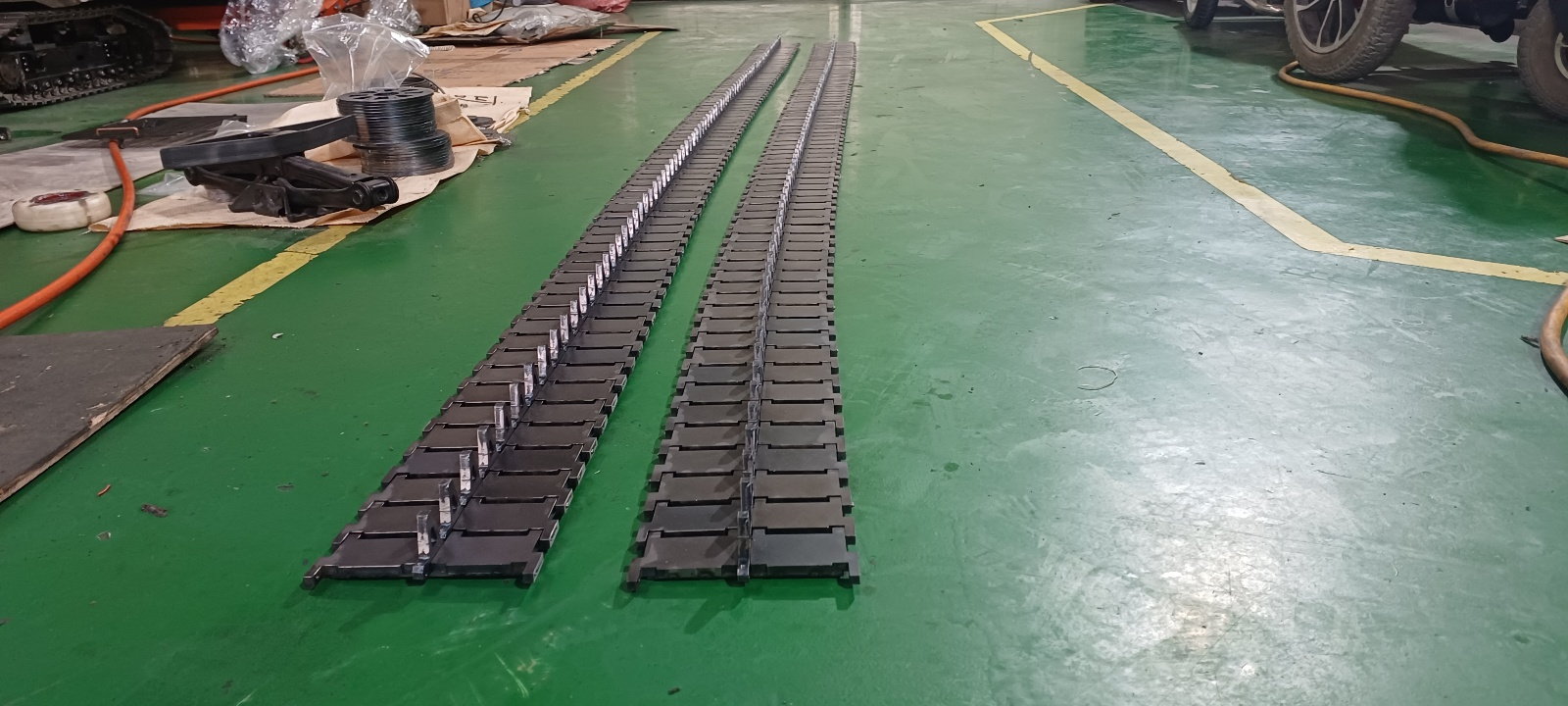

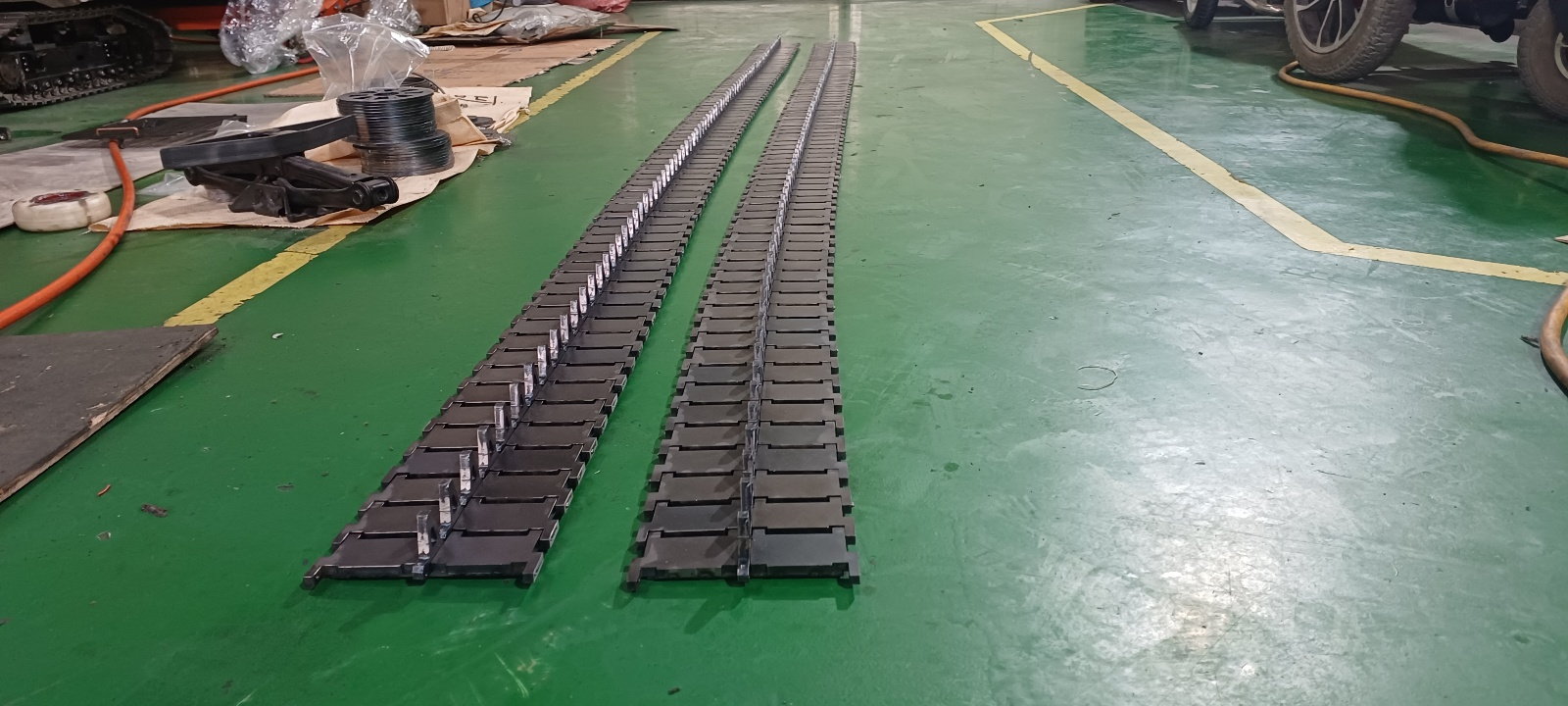

160 sets of finished products

Arrange for final assembly of the caterpillar using a square pipe.

Arrange 20 sets of caterpilers while trimming holes.

Start welding while adjusting spacing

Perform spot welding vertically and horizontally to prevent duplication or omission.

Welding is done by argon gas.

Inspection after welding

motion inspection

Array inspection

20 sets are complete.

40 sets are complete.

To be continued in the next episode.

Please refer to the following for the production video.

Smaller to make holes for fixing pins in the continuous caterpillar body

Caterpillar body parts with hole process completed

Pre-assembly for validation

3mm diameter piano steel wire to be used as a caterpillar fixing pin

To fit the length, a pin. If you want to see this work, please refer to the 2022 K2 production video.

Use a hand drill and belt grinder to remove burrs from the cut fixing pins.

Produced one set for validation

Complete a set by welding

Rubber pad fixing parts and center guide spot welding

Position Calibration

160 sets of finished products

Arrange for final assembly of the caterpillar using a square pipe.

Arrange 20 sets of caterpilers while trimming holes.

Start welding while adjusting spacing

Perform spot welding vertically and horizontally to prevent duplication or omission.

Welding is done by argon gas.

Inspection after welding

motion inspection

Array inspection

20 sets are complete.

40 sets are complete.

To be continued in the next episode.

Last edited by PE YOUNG; 03-03-2023 at 05:18 PM.

The following 3 users liked this post by PE YOUNG:

#11

So labor intensive!

#12

Thread Starter

The project name of the tank production story I'm introducing is "ic2504", not "is2504". I'm informing you separately because I can't modify the text of the past anymore.

Regards,

Young

Regards,

Young

The following users liked this post:

Pcomm1.v2 (07-19-2023)

#13

Thread Starter

Both the ic2504's track assembly and track welding have been successfully completed.

I will share videos and photos related to the work next weekend.

1/5 scale K2 Black Panther MBT's shoes have been welded. 160 pieces were produced, 80 each on the left and right sides.

The photo shows the 2022 1/5 scale K2 Black Panther tank with Korean comedian Kwon Jae-kwan.

Can you estimate the size of the 1/5 scale K2 Black Panther tank?

The K2 Black Panther tank, the current 3.5th generation tank built in 2022, is being rebuilt in 2023 on a 1/5 scale. Please look forward to it.

Regards,

Young

I will share videos and photos related to the work next weekend.

1/5 scale K2 Black Panther MBT's shoes have been welded. 160 pieces were produced, 80 each on the left and right sides.

The photo shows the 2022 1/5 scale K2 Black Panther tank with Korean comedian Kwon Jae-kwan.

Can you estimate the size of the 1/5 scale K2 Black Panther tank?

The K2 Black Panther tank, the current 3.5th generation tank built in 2022, is being rebuilt in 2023 on a 1/5 scale. Please look forward to it.

Regards,

Young

Last edited by PE YOUNG; 03-05-2023 at 03:42 AM.

#14

Thread Starter

#16

Thread Starter

In 1/5 scale that's going to be a very large tank. I'll be looking forward to seeing the process unfold as this thing comes to fruition. It's also an opportunity for me to pass on a little information. The conservation and preservation of our big cats is a personal passion of mine. That's why I know that there's actually no such thing as a black panther. Black panther is just a catch-all term that's used to describe any big cat with a black coat. What people call black panthers are usually leopards or Jaguars that have a genetic defect that makes the fur appear solid black, but if you look very close so you can still see the spots. Leopards and Jaguars are very opportunistic and very adaptable and that's why they're doing better than lions or tigers. My very favorite, the cheetah, is technically not a big cat and that's the lesson for today, what is and is not a big cat? It's pretty simple really, in order to qualify for the big cat club, you must have the ability to roar, and you must not have the ability to purr. Lions, tigers, leopards and Jaguars are the only cats that can roar and are the only cats that are considered to be true big cats. Personally, I don't think that's entirely fair, I think cheetahs and mountain lions should also be included as big cats, but neither can roar and they both can purr. If you've ever seen the video, a 150 lb mountain lion purring is a pretty amazing thing to see. So I hope you guys will remember, if we don't start to care about these wonderful and Majestic animals we're going to lose them. Do you want to be the person that has to tell your grandchildren that we used to have lions and tigers but we don't anymore because nobody cared? Sorry to go off topic like that, but like I said, this is a real passion with me. If people don't start to give a crap, these Regal mammals will go extinct in our lifetimes. Just something to think about.

#17

Thread Starter

#19

So thanks for posting this thread, I'll be watching.

The following users liked this post:

PE YOUNG (03-15-2023)

#20

Thread Starter

Thanks for understanding, and once again, my apologies for hijacking your thread like that. But this thread did lead me to look into the K2 and that is a very cool tank. Built entirely by South Korea using only indigenous technology it has features that are pretty amazing. Like, each road wheel can be individually controlled so the tank can kneel or lean in any direction that it wants to. I saw that both Poland and turkey plan to buy these tanks, which are built by Hyundai. I also learned that this is the most expensive tank built to date. And there's also a very, very cool variant, the k600. It's the Minefield breaching variant and man, that is one very cool machine. Before this thread I had no idea that South Korea was designing and building their own tanks, and I think it said that when it's all over with the South Korean army will have 300 of these bad boys. For anyone that wants to learn more there is a lot of very good information at military-today.com and they also have a link to the k600. I wonder if the K2 kit could be converted to a k600? That would take a lot of time and skill, but the two of them side by side would be one hell of a model display.

So thanks for posting this thread, I'll be watching.

So thanks for posting this thread, I'll be watching.

#21

Thread Starter

A test drive photo of the 2022 K2 Black Panther.

In the summer of 2023, the producer will test-drive a desert version of a 1/5 scale k2 Black Panther tank.

Last edited by PE YOUNG; 03-05-2023 at 08:19 PM.

#22

Thread Starter

There is a modeling video of the K2 tank, the main tank of the Korean Army, so I share the link for your reference.

The video below has nothing to do with this tank manufacturing process and is a reference video to understand the shape of K2.

Young

The video below has nothing to do with this tank manufacturing process and is a reference video to understand the shape of K2.

Young

Last edited by PE YOUNG; 03-07-2023 at 10:06 PM.

The following users liked this post:

Pah co chu puk (03-08-2023)

#23

That was fun to watch. It was cool to see how you developed the various bodies and components to make up the tank shape. That would give you a bunch of solid bodies all joined. How did you convert that to a shell type assembly that can have space inside for the electronics and motors?

I've designed some things in Fusion 360 too, but clearly you are more skilled and adept at using the software than I am.

I've designed some things in Fusion 360 too, but clearly you are more skilled and adept at using the software than I am.

#24

Thread Starter

That was fun to watch. It was cool to see how you developed the various bodies and components to make up the tank shape. That would give you a bunch of solid bodies all joined. How did you convert that to a shell type assembly that can have space inside for the electronics and motors?

I've designed some things in Fusion 360 too, but clearly you are more skilled and adept at using the software than I am.

I've designed some things in Fusion 360 too, but clearly you are more skilled and adept at using the software than I am.

Young

#25

Thread Starter

In this episode, I will introduce you to the process of completing all the shape assembly and welding of the track that was in production last time and starting to produce the K2 tank bogie wheels.

Regards,

Young

Following the last episode, the process of assembling and welding the caterpillar in one batch continuously to form 20 pieces.

Track Parts Completed in a Bundle of 20

The last caterpillar that has been assembled and welded.

Afterwards, the work should be completed one by one and round the area in contact with the drive sprocket, and the center guide should be sharpened. Finally, a rubber pad will be installed underneath.

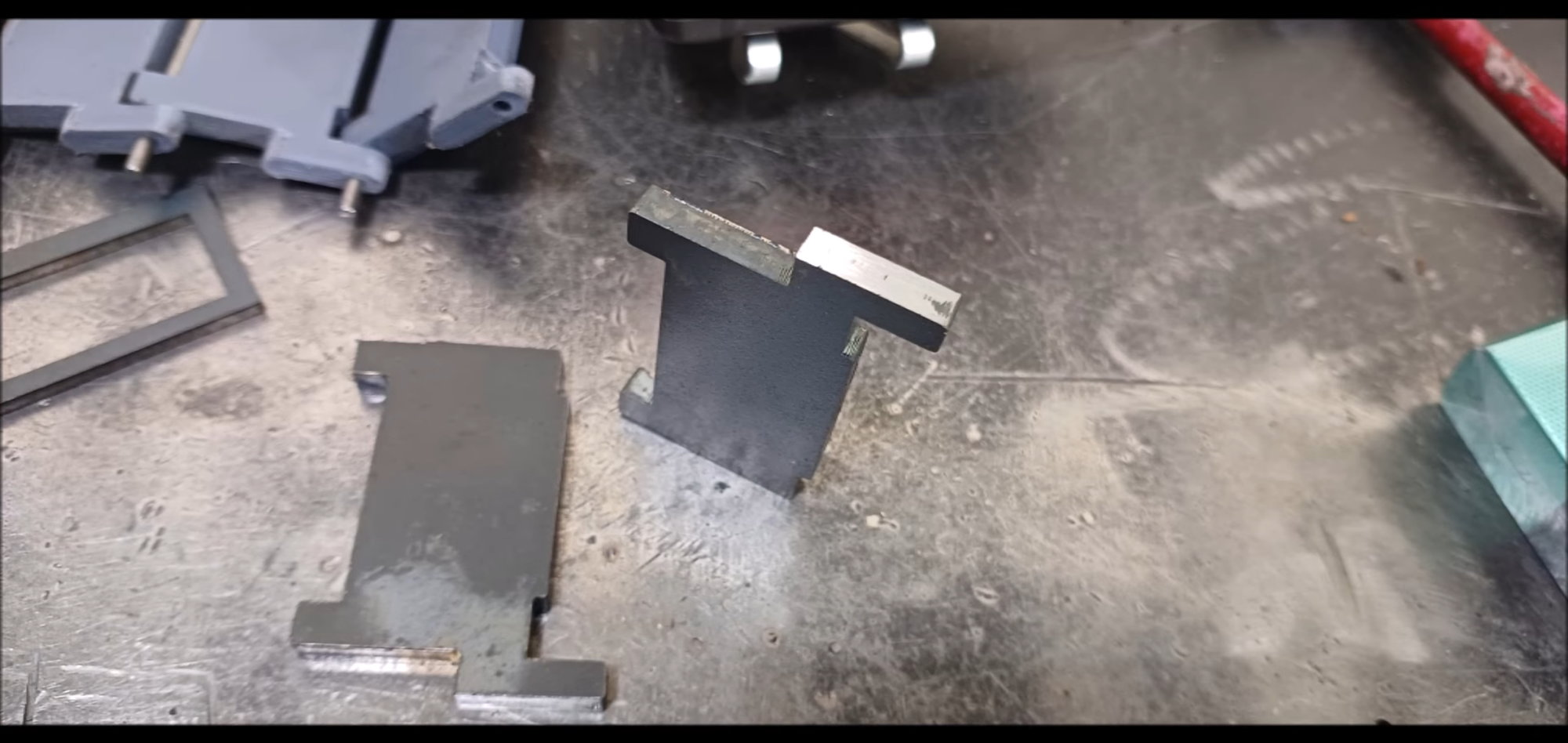

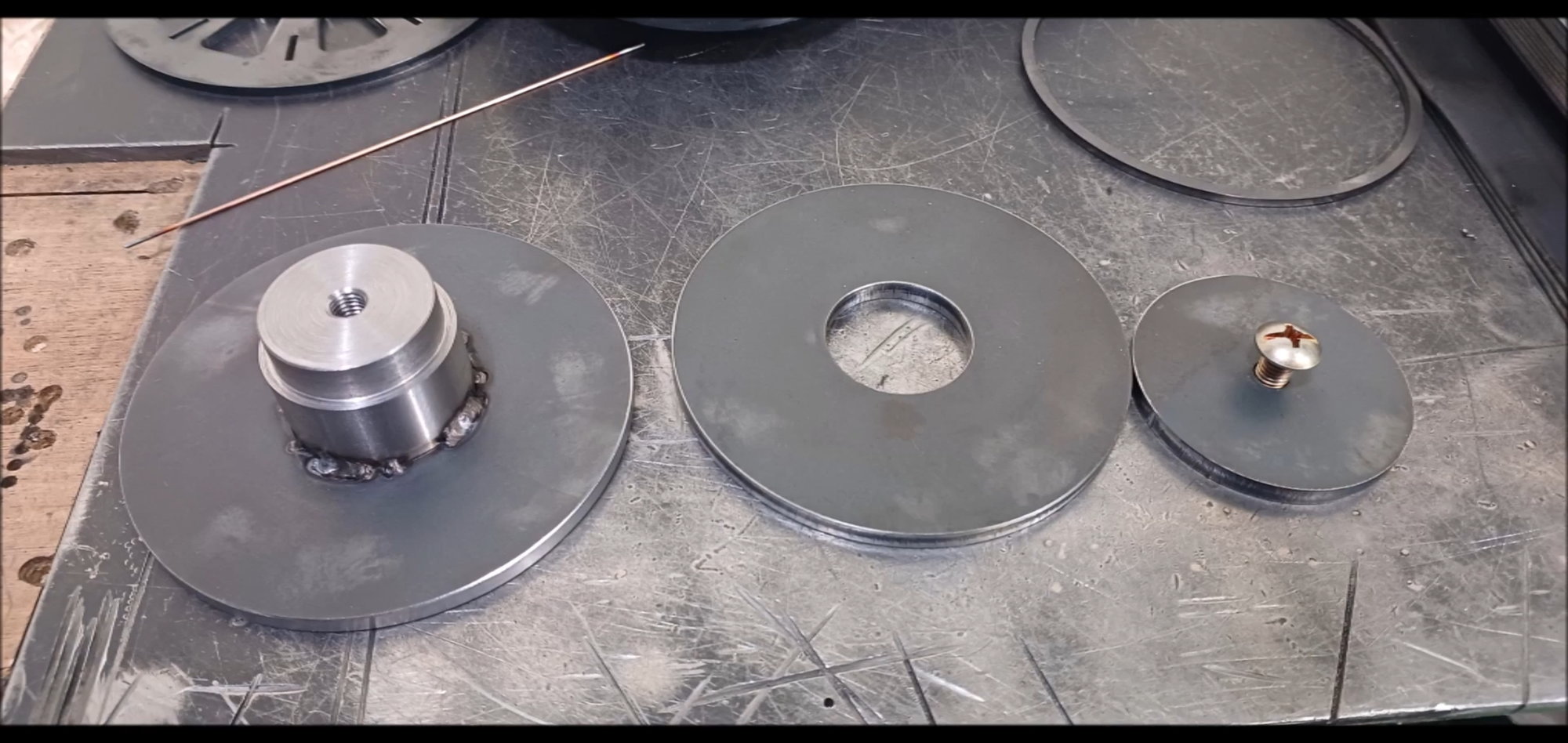

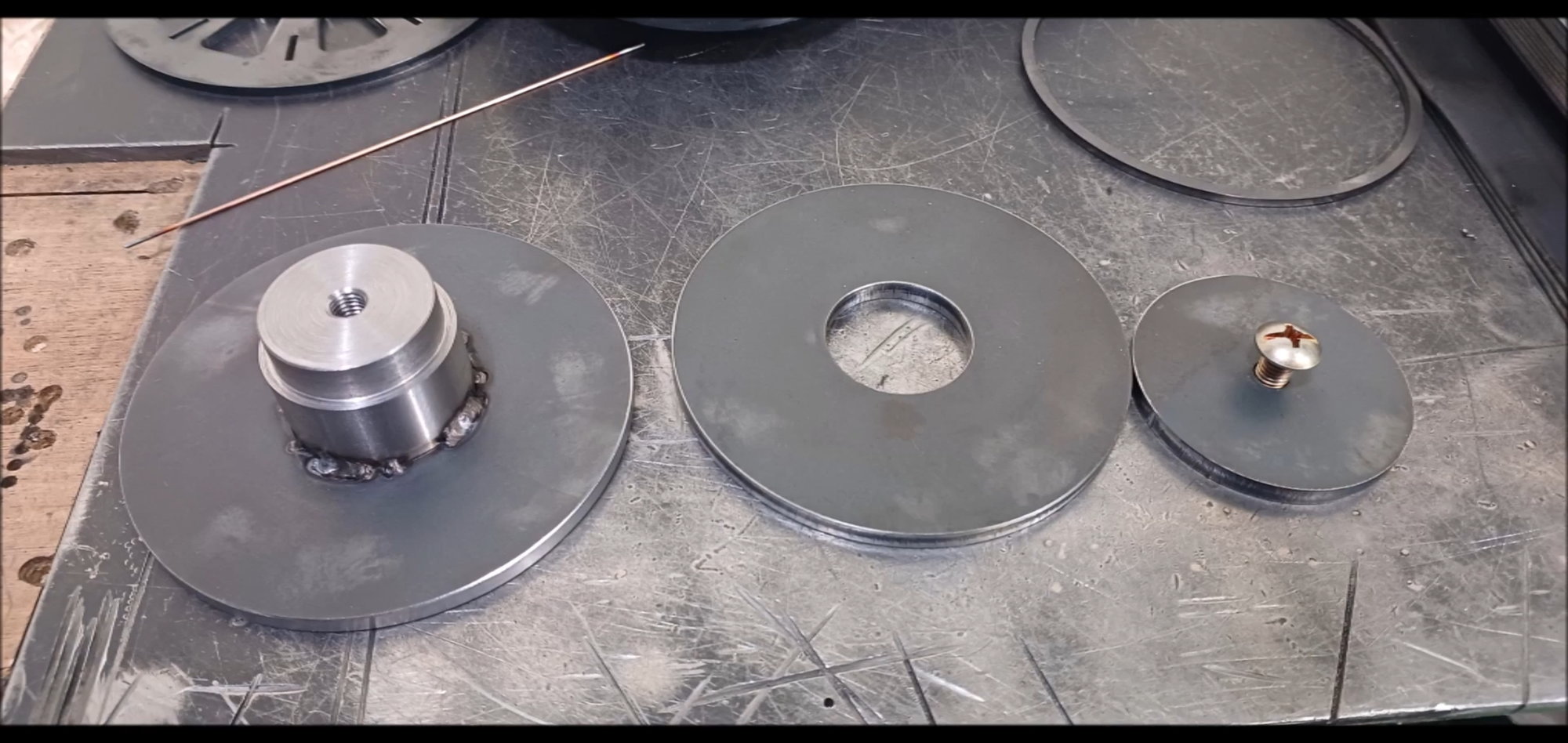

Laser machining parts for fabricating bogie wheels

an instrument for fixing the center and height

Bogie wheel Fabrication

bogie wheel parts with burr removed

Wheel support

The appearance of processing steel plates on tools for rolling irons

Bending completed bogie wheels. Usually, large-diameter pipes are cut to make them, but 1/5 scale K2 is difficult to find a standard pipe. Therefore, as it is now, the steel plate is bent to manufacture the wheel directly.cess of bending a steel plate to make a bogie wheel

Primary workpiece without wheel reinforcement

The process of welding wheel reinforcement components

The process of positioning the wheel reinforcement components

The process of welding the wheel reinforcement part in the circumferential direction

Welding without omission

Inspection after sample production

After the sample production, it is decided to weld the reinforcing parts by covering the bending marks.

Welding reinforcing parts by covering bending marks

a finished wheel The wheels will be made 27 more in the future.

To be continued in the next episode.

Regards,

Young

Following the last episode, the process of assembling and welding the caterpillar in one batch continuously to form 20 pieces.

Track Parts Completed in a Bundle of 20

The last caterpillar that has been assembled and welded.

Afterwards, the work should be completed one by one and round the area in contact with the drive sprocket, and the center guide should be sharpened. Finally, a rubber pad will be installed underneath.

Laser machining parts for fabricating bogie wheels

an instrument for fixing the center and height

Bogie wheel Fabrication

bogie wheel parts with burr removed

Wheel support

The appearance of processing steel plates on tools for rolling irons

Bending completed bogie wheels. Usually, large-diameter pipes are cut to make them, but 1/5 scale K2 is difficult to find a standard pipe. Therefore, as it is now, the steel plate is bent to manufacture the wheel directly.cess of bending a steel plate to make a bogie wheel

Primary workpiece without wheel reinforcement

The process of welding wheel reinforcement components

The process of positioning the wheel reinforcement components

The process of welding the wheel reinforcement part in the circumferential direction

Welding without omission

Inspection after sample production

After the sample production, it is decided to weld the reinforcing parts by covering the bending marks.

Welding reinforcing parts by covering bending marks

a finished wheel The wheels will be made 27 more in the future.

To be continued in the next episode.

Last edited by PE YOUNG; 03-12-2023 at 02:00 PM.

The following users liked this post:

Panther F (03-13-2023)